What Is A Slip Joint In Plumbing

Introduction:

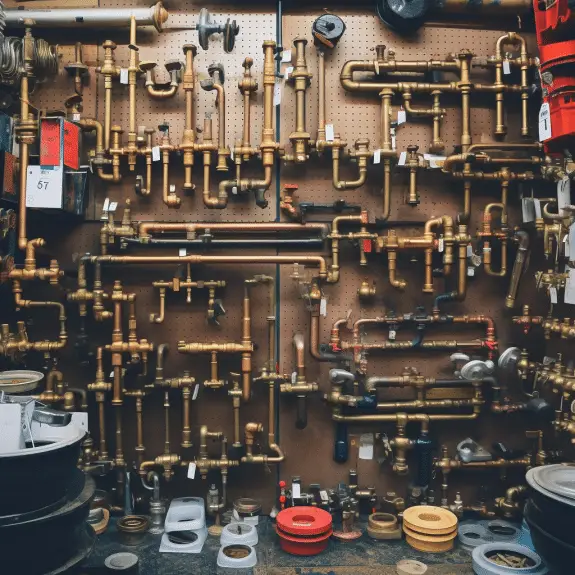

What Is A Slip Joint In Plumbing: In plumbing systems, slip joints are a fundamental component that allows for easy disassembly and reassembly of pipes and fittings. They play a crucial role in providing flexibility and convenience when it comes to plumbing installations and repairs. In this introduction, we will explore what slip joints are, their purpose in plumbing systems, and their significance in ensuring efficient and adjustable connections.

A slip joint, also known as a compression joint or slip nut connection, is a type of connection that enables the joining of pipes or fittings without the need for soldering or gluing. The slip joint consists of two main parts: a slip nut and a slip washer or compression ring. This design allows for the easy adjustment and removal of pipes or fittings, making slip joints highly versatile and practical in plumbing applications.

The primary purpose of slip joints in plumbing is to provide flexibility in connecting and disconnecting pipes and fittings. They allow for adjustments in length and angle, making it easier to align and fit the pipes properly. This adjustability is especially useful when dealing with installations or repairs that require precise positioning or when working in tight spaces.

What is the purpose of the slip joint?

The slip joint is a mechanical device commonly used in various applications to allow relative movement between two connected parts. Its primary purpose is to accommodate variations in length, compensate for misalignment, or facilitate disassembly and maintenance.

Another important purpose of slip joints is to facilitate easy disassembly and maintenance. By incorporating a slip joint, components can be quickly and easily separated without the need for complex disassembly procedures.

What is slip joint also known as?

In rare circumstances, the internal friction force is so great that the joint loses its ability to bend. A slip joint, also known as an adjustable joint or sliding joint, is a type of mechanical connection that allows for limited movement between two components.

The slip joint gets its name from the ability of the joint to slide or slip along its length. It consists of two components, typically cylindrical or tubular in shape, that fit together with overlapping sections. The overlapping sections create a gap that allows for movement.

One of the key features of a slip joint is its adjustability. This adjustability is particularly useful in situations where precise measurements or alignment may vary. The ability to adjust the length of the joint makes installation and repair easier, as it allows for slight variations in pipe positioning.

What is the difference between a slip joint and a coupling?

Slip couplings provide an easy way to make minor repairs or adjustments without replacing an entire section of pipe, while couplings provide an effective way to join two separate lengths of pipe together in underground applications. While they both serve the purpose of connecting two components, there are significant differences between them.

A slip joint, also known as a slip joint fitting or slip nut, is a type of connection that allows for limited movement and adjustment. It typically consists of two components: a slip nut and a slip washer. The slip nut can slide along the length of the fitting, while the slip washer provides a seal. This design allows for easy assembly and disassembly without the need for special tools.

On the other hand, a coupling is a type of connection that provides a rigid and permanent joint between two components. It is typically used to join two pipes or shafts together securely. Couplings come in various forms, such as rigid couplings, flexible couplings, and compression couplings. They provide a more robust and permanent connection that ensures stability and alignment between the connected components.

What are the parts of a slip joint?

A slip joint is a type of mechanical joint that allows for limited axial movement between two components. It is commonly used in various applications, including plumbing, automotive, and mechanical assemblies. The slip joint consists of several essential parts that enable its functionality.

Pipe or Tube

The slip joint involves two pipes or tubes that are designed to fit together. These pipes are usually cylindrical in shape and have specific dimensions to ensure a proper fit.

Slip Nut

A slip nut is a threaded nut that is used to secure the slip joint assembly. It has internal threads that match the external threads on the pipe or tube. The slip nut allows for adjustment and tightening of the joint.

Washer

A washer is often placed between the slip nut and the slip joint to provide a seal and prevent leakage. It acts as a gasket and helps create a watertight connection.

Friction Ring

The friction ring is a vital component of the slip joint assembly. It is a circular ring made of rubber or plastic that fits around the pipe or tube. The friction ring creates a tight seal when compressed, preventing water or fluid from leaking.

Slip Joint Adapter

The slip joint adapter connects the slip joint assembly to another component, such as a drain or faucet. It typically has male threads on one end and a slip joint connection on the other.

By combining these components, the slip joint allows for adjustable and leak-resistant connections between pipes or tubes, providing flexibility and ease of assembly and disassembly in various applications.

What are the different types of slip joints?

There are several different types of slip joints, each with its own unique design and application.

Sleeve Slip Joint

This is the simplest type of slip joint, consisting of a cylindrical sleeve that slides over two connected components. It allows for axial movement but does not provide any rotational flexibility.

Universal Joint

Also known as a Cardan joint, it consists of two yokes connected by a cross-shaped intermediate member. It provides flexibility in both axial and angular movements, allowing the connected components to move in different directions.

Constant Velocity Joint (CV Joint)

These joints are commonly used in automotive applications to transmit torque while accommodating variable angles. They employ a set of ball bearings or tripod rollers to maintain a constant velocity, reducing vibrations and ensuring smooth power transmission.

Which type of joint is used for plumbing?

Pipes having different diameters are suitable for this type of joint. Solder is a low-melting-point alloy that flows between the joint, creating a strong and watertight connection.

They provide a secure and leak-free connection, making them suitable for both water supply and drainage systems. Additionally, soldered joints are relatively easy to create and require minimal tools and materials.

Where is the slip joint located?

The slip joint is in the back of the transmission on most live axle, leaf sprung rear ends (the Hotchkiss system). It’s actually a yoke that slides on splines on the output shaft. These typically move in and out less than an inch in a regular car, across the available suspension travel.

The slip joint is a mechanical joint commonly found in plumbing systems. It is typically located in a section of a pipe where there is a need for adjustment or disconnection. The slip joint consists of two components: a slip nut and a slip washer.

The slip nut is a threaded collar that can be tightened or loosened by hand, while the slip washer is a flexible gasket or washer placed between the slip nut and the adjoining pipe or fitting. This design allows for easy assembly and disassembly of the joint without the need for specialized tools.

The slip joint is often used in applications such as sink drains, P-traps, and other plumbing connections that require periodic maintenance or adjustments. It provides a convenient way to connect and disconnect pipes or fittings without the need for permanent soldering or gluing.

What are slip joints in construction?

Slip joint is installed in junctions of brickwork and concrete to allow for low friction movement between differing materials due to the expansion and contraction caused over time. It aids in preventing the cracking of bricks or mortar over time.

Slip joints in construction refer to a type of connection or joint between two structural elements that allows for limited movement or displacement. The purpose of slip joints is to prevent excessive stress or damage that could result from the rigid connection of structural elements.

Conclusion

A slip joint is a crucial component in plumbing that allows for the disassembly and reassembly of pipes and fittings. It is a simple yet effective mechanism that provides flexibility and convenience in plumbing systems. The slip joint consists of two parts: a slip nut and a slip washer. This design allows for easy installation and removal of pipes and fittings without the need for specialized tools or adhesives.

The slip joint plays a significant role in various plumbing applications, particularly in connecting drainpipes and traps under sinks, toilets, or other fixtures. It allows for adjustments in length and angle, making it easier to align and fit the pipes properly. This versatility and convenience make slip joints a common and essential feature in many plumbing installations.

Understanding the purpose and functionality of slip joints is essential for both professional plumbers and homeowners. It allows for efficient plumbing installations and repairs, ensuring proper alignment and secure connections. Whether it’s replacing a trap or adjusting the height of a drainpipe, slip joints provide the flexibility and ease of use required for these tasks.