What Is A Closed Plumbing System

Introduction

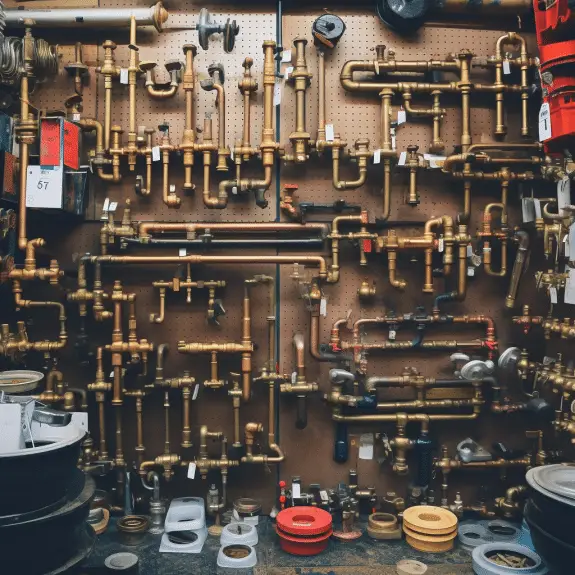

A closed plumbing system, also known as a closed-loop plumbing system, is an essential component of modern indoor plumbing infrastructure designed to ensure the efficient and safe distribution of water throughout a building.

Unlike an open plumbing system, which relies on gravity for water flow, a closed plumbing system utilizes a network of pressurized pipes and valves to create a controlled water distribution system. The key characteristic of a closed plumbing system is the presence of a backflow prevention device, which prevents the contamination of potable water by backflow or the reversal of water flow.

Closed plumbing systems offer several advantages over open systems. Firstly, they provide enhanced control over water pressure, allowing for consistent and reliable water supply to different fixtures and appliances within the building. Secondly, they minimize the risk of water contamination by preventing cross-connections and backflow, ensuring the safety and purity of the water supply. Additionally, closed plumbing systems are more energy-efficient, as they can incorporate recirculation systems and water-saving technologies.

Why Is Thermal Expansion Important In Closed Plumbing System?

The valve opens to release pressure and leak water when thermal expansion causes excess water in the hot water system. If your relief valves leak, don’t worry—they’re working! This protects plumbing equipment and piping.

Understanding thermal expansion is critical to preserving closed plumbing systems’ integrity and performance. Residential and commercial buildings have closed plumbing systems with sealed fluid flow.

Thermal expansion in closed plumbing systems is important because fluids react to temperature changes. The volume of a fluid like water increases with temperature. Fluid compresses when temperature drops. In a closed plumbing system, heat fluctuations can cause significant pressure changes.

The increased pressure from fluid expansion can damage pipes, fittings, and other components in a closed plumbing system without thermal expansion. Overpressure can cause leaks, cracks, or burst pipes, causing water damage, supply loss, and costly repairs.Installation of expansion tanks is a frequent solution. By adding space for the expanding fluid, these tanks reduce system pressure.

What Is A Loop System In Plumbing?

A loop system in plumbing uses a continuous loop of pipes to swiftly and efficiently transport hot water to building fixtures and appliances. This design ensures hot water is accessible at every point of use without delay or temperature loss.

A loop system connects a primary hot water pipe to a manifold for central distribution. Hot water fixtures and appliances receive smaller branch connections from the manifold. These branch pipes form a building-wide loop to maintain hot water flow. The loop system uses “demand-controlled circulation”.

Loop systems engage the circulation pump only when hot water is needed at a fixture or appliance, unlike typical plumbing systems. This saves electricity and water. A flow-activated pump monitors demand and circulates hot water from the loop to the fixture or appliance almost quickly. Loop system ensures continuity

What Is The Difference Between Closed And Open System?

The environment can interchange energy and matter with an open system. An open cooktop system loses heat and water vapor to the air. Unlike open systems, closed systems can only exchange energy with their environment.

The exchange of matter and energy with the environment distinguishes closed and open systems.

A closed system exchanges heat or work but does not transmit matter. Thus, energy can enter and leave the system but not mass. A sealed container with a fixed amount of gas is a closed system. Gas molecules can move and collide inside the container, but none can enter or leave.

However, an open system can interchange matter and energy with its surroundings. Mass and energy can cross its bounds. A stovetop pot of boiling water is an open system. It applies to engineering, ecology, and information systems.

What Is Closed Plumbing System?

A closed plumbing system contains the water supply in a closed loop. This technology isolates water from pollutants by circulating it via pipes.

A closed plumbing system distributes water from a main line to building fixtures and appliances. The pipelines deliver hot and cold water to various locations.

Backflow prevention devices are essential to closed plumbing systems. They prevent contamination by preventing water from entering the main supply or mixing with potable water.

Commercial, residential, and industrial buildings use closed plumbing systems. They improve water quality, manage water pressure, and reduce contamination. Keeping the water supply separated in the closed loop reduces the risk of external contaminants, bacteria, and chemicals.

How Do I Know If My Plumbing System Is Closed?

A closed plumbing system has a backflow prevention device like a check valve or pressure-reducing valve attached to the main water shutoff valve. Check for backflow prevention devices in your plumbing system.

Closing plumbing systems stabilizes water pressure better than open systems. Lack of direct external connections: Closed plumbing systems insulate water from pollutants and external sources. Check for direct connections to wells or untreated water supplies.

Additional components: Closed plumbing systems may have additional components for efficiency and usefulness. Expansion tanks, pressure regulators, and circulation pumps are examples. Such components in your plumbing system indicate a closed configuration.

Why Is A Closed Plumbing System Necessary?

Closed plumbing prevents public water contamination. Without a backflow protection mechanism, contaminated building plumbing water could contaminate the public water supply. A closed plumbing system ensures water supply safety, efficiency, and reliability. Closed plumbing systems matter because:

Closed plumbing systems prevent water backflow and pollutant contamination of drinking water. Backflow preventers and check valves reduce external contamination. Plumbing closures prevent contaminants, chemicals, and microbes from entering water. A closed loop isolates the water from outside pollutants.

Building water pressure is improved by closed plumbing systems. Closed-loop water delivery reduces external pressure changes. This stabilizes fixture and appliance water pressure. Closed plumbing systems distribute hot water efficiently. The closed loop design speeds hot water delivery, reducing wait time and waste.

When properly built and maintained, a closed plumbing system can extend plumbing infrastructure life. By minimizing corrosion and rapid pressure changes, pipes and components are less prone to leak or break.

Where Are Closed Plumbing Systems Typically Used?

Residential buildings: Closed plumbing systems can be found in residential properties such as houses, apartments, and condominiums. They provide a reliable water supply and help ensure consistent water pressure throughout the building. Additionally, closed systems are beneficial for efficient hot water distribution, reducing waiting times and conserving water.

Commercial buildings: Many commercial buildings, including office complexes, shopping centers, and hotels, utilize closed plumbing systems. These systems are essential to meet the high water demands of various occupants and activities within the building.

Industrial facilities: Closed plumbing systems are prevalent in industrial facilities where maintaining water quality and preventing contamination are critical. Industries such as pharmaceuticals, food processing, and manufacturing often employ closed systems to ensure the purity and integrity of their processes.

Healthcare facilities: Hospitals, clinics, and other healthcare facilities require strict adherence to hygiene and sanitation standards. Closed plumbing systems play a crucial role in preventing the spread of infections and diseases. They help maintain water quality and prevent the backflow of contaminated water into the potable water supply.

Are Closed Plumbing Systems Required By Building Codes?

Closed plumbing systems are required in many building codes to protect the public water supply. Please consult local plumbing codes.

Local construction codes define closed plumbing system requirements. Plumbing is regulated by local construction rules to ensure safety, functionality, and efficiency.

Some construction codes require or recommend closed plumbing. To reduce pollutants, enhance water quality, and improve distribution, building codes demand closed plumbing systems. Following scenarios may require or encourage closed plumbing systems:

Many construction rules demand closed plumbing systems for high-rise structures due to water distribution complexity and the need to maintain water pressure.

Building codes may restrict plumbing systems in offices, hotels, hospitals, and schools. These plants demand more water and stricter pollution and water quality standards.

To maintain water purity, pharmaceuticals, food processing, and laboratories may need closed plumbing systems.

Conclusion

A closed plumbing system is an integral part of modern plumbing infrastructure that plays a crucial role in ensuring the efficient and safe distribution of water within a building. By utilizing a network of pressurized pipes and valves, along with backflow prevention devices, closed plumbing systems offer numerous advantages over open systems.

One of the key benefits of a closed plumbing system is its ability to provide consistent water pressure throughout the building, enabling reliable water supply to various fixtures and appliances. This ensures optimal performance and user satisfaction. Moreover, closed systems prevent the risk of water contamination by eliminating the possibility of backflow, thereby safeguarding the quality and purity of the water supply.

Another advantage of closed plumbing systems is their energy efficiency. They can incorporate recirculation systems and water-saving technologies, reducing water wastage and energy consumption. This not only benefits the environment but also leads to cost savings for the building owner. The components of a closed plumbing system, including pipes, valves, pumps, and backflow prevention devices, work together to create a closed-loop system that effectively manages the distribution of water and the disposal of wastewater. These components are crucial for maintaining the integrity and functionality of the system.