What Is An Angle Stop In Plumbing

Introduction:

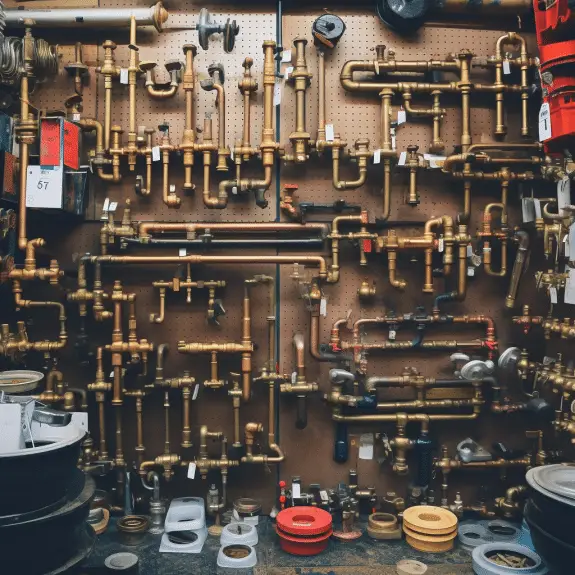

Plumbing Angle Stops: Angle stops control water flow to specified fixtures and appliances. It is a valve that lets people turn off water to a specific region without impacting the plumbing system. This essay discusses angle stops in plumbing, their function, and their relevance in plumbing maintenance and repair.

An angle stop, angle valve, or angle shut-off valve is essential to plumbing projects. It usually links water supply lines to sinks, toilets, and dishwashers. To cut off the water supply to a fixture for repairs, replacements, or maintenance without interrupting the plumbing system, this valve is easy to use.

The angle stop valve is designed to be user-friendly, featuring a handle or lever that can be easily turned to open or close the valve. When the valve is open, water flows freely from the supply line to the plumbing fixture, enabling normal operation. However, when the valve is closed, it blocks the water flow, effectively shutting off the water supply to the fixture. This functionality proves invaluable in situations such as leak repairs or fixture replacements, where isolating the water flow to a specific area is necessary to prevent water damage or inconvenience.

What is angle vs straight stop?

On a straight stop valve, the inlet and outlet are aligned. Straight valves are typically found where the supply line comes through the floor. On an angle valve, the outlet is at a 90-degree angle from the supply line. Angle valves are used on supply lines that come from the wall.

Angle and straight stops are two types of shut-off valves used in plumbing systems to control the flow of water. The main difference between them lies in their orientation and the direction of the water pipe connection.

Angle stops, also known as angle valves, are L-shaped with 90-degree inlets and outlets. Water supply lines that angle out of the wall or floor usually employ this stop valve. The angle stop has an inlet that connects to the water supply line and an outlet to the fixture or appliance. The angle shape makes installation and accessibility straightforward, especially in confined locations where a straight stop valve may not fit.

However, a straight stop, also known as a straight valve, has a linear input and output. This valve is utilized when the water supply line exits the wall or floor vertically or horizontally. Inlet and output connect to the water supply line and fixture or appliance, respectively, in the straight stop valve.

What is the purpose of the angle stop?

Why use an Angle Valve? When upgrading or replacing your faucet or other fixtures or needing repairs, you can use the angle stop valve to turn off water to only that appliance or fixture.

Angle stops in plumbing regulate water flow to certain fixtures and appliances. It functions as a valve to enable or halt water flow to a specific location without impacting the plumbing system.

The angle stop is used to easily turn off water to specific fixtures during maintenance, repairs, or emergencies. Users can isolate water flow to a fixture without interrupting other plumbing system areas by adjusting the angle stop handle or lever. This ability to selectively control water supply is useful when fixing a faulty faucet, changing a fixture, or doing maintenance.

Angle stops help avoid water damage and reduce dangers. The angle stop shuts off water to a ruptured pipe or malfunctioning fixture in a plumbing emergency.

What is the most common angle stop?

It is normal for angle stops to be made of metal or plastic, and they are usually pretty small. The most common sizes are ¼ inch, ⅽ inch, and half-inch. Most of the time, angle stops are found under your home equipment.

Most of the time, the compression angle stop valve is used as an angle stop in pipes. This valve is commonly used in both home and business water systems because it is simple, works well, and is easy to install.

On one end of the compression angle stop valve is a threaded connection that fits onto the water supply line. On the other end is a compression nut that holds the valve in place at the fixture’s inlet. The valve can also be opened or closed by turning a handle or lever.

The name “compression” comes from the way the valve seals off the water. There is a small washer made of rubber or plastic inside the valve. This washer is called a compression ring or ferrule. The compression nut pulls the washer against the pipe when it is tightened on the valve. This makes a tight seal that stops water from leaking.

The fact that the compression angle stop valve can be used in different ways is one of its benefits. It works with different kinds of pipes, like copper, PEX, and CPVC. It also works with pipes of different sizes, which makes placement easy in a variety of plumbing systems.

What size is angle stop?

Angle or straight stops have an inlet that is either 1/2″ fip (female iron pipe) or 5/8″ o.d. copper compression. The 1/2″ fip stops are for attaching to threaded pipe nipples. The copper compression fittings are designed to attach to the smooth outside surface of copper pipe.

Angle stops, or angle valves, come in different sizes to accommodate various plumbing configurations. The most common sizes for angle stops are 1/2 inch and 3/8 inch. These measurements refer to the diameter of the pipe that the angle stop connects to.

The 1/2 inch angle stop is the standard size for most residential plumbing applications. It is commonly used for sinks, toilets, and other fixtures in homes. The 1/2 inch angle stop typically connects to 1/2 inch copper, PEX, or PVC supply lines.

The 3/8 inch angle stop is typically used for smaller fixtures such as bathroom faucets or appliances that require a smaller water supply line. It is commonly found in compact or low-flow installations. The 3/8 inch angle stop connects to 3/8 inch supply lines.

How long do angle stops last?

After 8-10 years or even one use, the compression component of the valve that stops water fails.

Angle stops’ longevity depends on valve quality, material, and plumbing system usage and maintenance. Angle stops are usually durable, however they may wear out with time.

Brass or chrome-plated brass angle stops survive longer than plastic ones. Brass valves are used for plumbing due to their corrosion resistance and durability.

Angle stop longevity is also affected by water quality and pressure. Hard water with high mineral content or corrosive water may deteriorate the valve. High water pressure in the plumbing system can further stress the angle stop, shortening its longevity.

What is the difference between angle valve and stop valve?

Most of the time, supply lines that go from the floor to the fixture right above it have straight stops on them. Angle Stops are made for supply lines that come out of the wall. In addition to their normal job, they also work as an elbow, sending the flow up and toward the fixture.

In plumbing, the terms “angle valve” and “stop valve” are often used to refer to the same valve. Their use or form may be a little different depending on the situation.

If you put an angle valve or angle stop valve between the water supply line and a device or appliance, it will turn off the water flow. The angle is usually 90 degrees. You can use this valve in tight spots like behind sinks or toilets. It is easier and takes up less space to install because the angle valve handle or switch can be reached at a right angle to the water supply line.

A stop valve, also called a stop and waste valve, is used for water and irrigation systems outside, though. To keep the water from freezing in the winter, it turns off and drains the supply line. Most stop valves are buried, and when they’re closed, they let water drain away.

Why are angle valves used?

What angle valves are usually used for is to regulate or control the flow and to reduce pressure. They may also have some influences on temperature. The mechanisms used to reach these functions may differ. For example, angle valves can be used as shutoff valves, needle valves, check valve or stop-check valves.

Angle valves, also known as angle stops or angle shut-off valves, are used in plumbing for several important reasons:

Control and Shut-off

Angle valves are mostly used to control and shut off water to specific fixtures and appliances. Users can easily switch off water flow to sinks, toilets, and dishwashers by installing an angle valve near them. During repairs, maintenance, or emergencies like leaks or burst pipes, this feature isolates the afflicted region without interrupting water delivery to the plumbing system.

Convenience and Accessibility

Angle valves are designed to be easily accessible. They are typically located close to the fixture they serve, allowing users to quickly reach and operate the valve without having to access the main water supply line. This convenience makes it simpler for homeowners or plumbers to perform tasks such as replacing fixtures, installing new appliances, or conducting routine maintenance without having to shut off water to the entire building.

Flexibility and Adaptability

Angle valves offer flexibility in plumbing installations. They come in different sizes and configurations to accommodate various pipe diameters and plumbing layouts. Additionally, angle valves are available in different materials, such as brass, chrome-plated brass, or plastic, providing options to suit specific plumbing needs and preferences.

Is an angle stop a fixture?

Another name for this valve is a compression valve. It is the emergency closing valve that is under every appliance and fixture in your home that uses water. Additionally, angle stops are a popular and low-cost plumbing part that can help you avoid spending thousands of dollars on repairs.

No, in plumbing terms, an angle stop is not a device. An angle stop is a valve that goes between the water line and a faucet, toilet, sink, or other fixture or appliance. For controlling the flow of water to the spigot, it fits into this hole. Even though an angle stop is an important part of water systems, it is not itself a fixture.

In plumbing, fixtures are things like sinks, toilets, showers, bathrooms, and other things that take in or send out water. It is necessary for these fixtures to have water to work because they are linked to the plumbing system. On the other hand, the angle stop valve controls the flow of water to a certain device as a separate unit.

Angle stop valves are useful because they make it easy to turn off the water to a certain device without affecting the rest of the plumbing. It lets you stop the flow of water to a certain fixture during maintenance, fixes, or emergencies.

Conclusion

An angle stop is a crucial component in plumbing systems that plays a significant role in controlling the flow of water. It is a valve installed between the water supply line and a fixture or appliance, such as a faucet, toilet, or dishwasher. The angle stop allows users to shut off the water supply to a specific fixture without affecting the rest of the plumbing system. This feature is particularly useful during maintenance, repairs, or emergencies.

The angle stop valve is typically located near the fixture it serves and is easily accessible. It consists of a handle or lever that can be turned to open or close the valve. When the valve is open, water flows freely to the fixture, allowing normal operation. However, when the valve is closed, it stops the water supply, preventing any further flow to the fixture.

The angle stop valve is designed to provide convenience and efficiency in plumbing systems. It allows for quick and easy shut-off of water to a specific area, enabling repairs or replacements without disrupting the entire water supply. In case of emergencies, such as a burst pipe or a leaking fixture, the angle stop valve can be quickly closed to prevent further water damage.

Additionally, angle stops are available in various materials, such as brass, chrome-plated brass, or plastic, to suit different plumbing needs and preferences. They come in different sizes to accommodate different pipe diameters and configurations.