How Long Does Cast Iron Plumbing Last

Introduction:

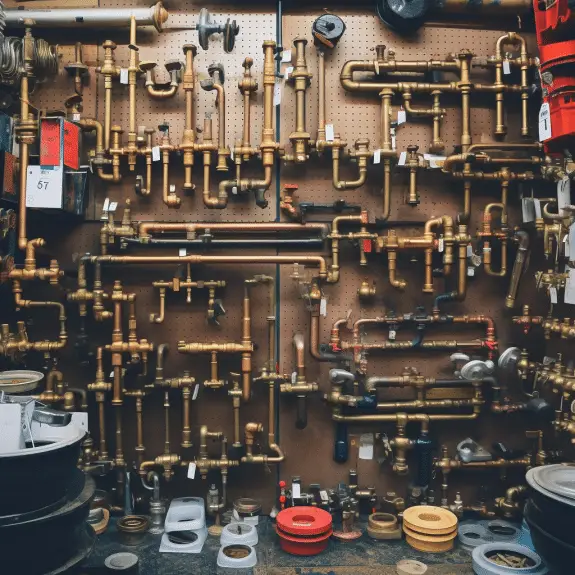

How Long Does Cast Iron Plumbing Last: Cast iron plumbing has been a popular choice for sewage and drainage systems in buildings for many decades. Its durability and strength have made it a reliable option for transporting wastewater and maintaining the structural integrity of plumbing systems. However, a common question that arises when considering cast iron plumbing is: How long does it actually last? In this introduction, we will explore the lifespan of cast iron plumbing, factors that can affect its longevity, and the importance of proper maintenance.

Cast iron plumbing has a reputation for being exceptionally durable, with a lifespan that can span several generations. In fact, it is not uncommon to find cast iron pipes that have been in use for over a century. The material’s high resistance to pressure, temperature changes, and physical impact contribute to its longevity. Cast iron plumbing is well-suited for handling the demands of wastewater disposal and drainage, making it a reliable choice for residential, commercial, and industrial applications.

While cast iron plumbing is renowned for its durability, there are several factors that can influence its lifespan. One of the primary considerations is the quality of installation. Proper installation techniques, such as ensuring secure joints and appropriate support, are crucial for the long-term performance of the plumbing system. Additionally, environmental factors play a role. Soil conditions, water acidity, and other external elements can affect the corrosion resistance of cast iron pipes, potentially reducing their lifespan.

Regular maintenance is essential for maximizing the lifespan of cast iron plumbing. Routine inspections can help identify any signs of corrosion, leaks, or blockages that may compromise the system’s integrity. Addressing these issues promptly through repairs or replacements can significantly extend the lifespan of the plumbing system. Furthermore, proactive measures such as applying protective coatings or liners can provide an additional layer of defense against corrosion and wear.

What is the longest lasting plumbing material?

PVC

Brass, cast iron, and galvanized steel have a lifespan of up to 100 years, copper can last over 50 years, and PEX and PVC usually last around 50 years.

Copper piping is commonly the longest-lasting. Copper pipes have been used in plumbing systems for ages and are corrosion-resistant. bacteria-resistant, making it a hygienic water carrier. Plumbing lasts 50 years or more with proper installation and upkeep.

Another durable plumbing material is brass. Brass, a copper-zinc alloy, is strong and corrosion-resistant. Plumbing systems employ brass pipes for faucets and valves. Brass plumbing, like copper, can last 50 years or more with careful care.

Additionally, stainless steel is durable in plumbing applications. Stainless steel pipes resist corrosion, rust, and scale. They tolerate high temperatures and pressures, making them excellent for household and industrial plumbing. Stainless steel plumbing is reliable and durable, lasting 50 years or more.

What is the life expectancy of cast iron pipes?

between 80-100 years

Cast Iron: Cast iron pipes last between 80-100 years, and are built to withstand a high amount of water pressure. However, like galvanized steel, cast iron piping has been found to be susceptible to rust over time. PVC (Polyvinyl Chloride): Traditionally, PVC piping only lasts between 25-40 years.

The life expectancy of cast iron pipes can vary depending on several factors, including the quality of the pipes, installation techniques, environmental conditions, and maintenance practices. In general, well-installed and properly maintained cast iron plumbing can last for several decades, often surpassing 50 years and even reaching up to 100 years or more.

One of the primary reasons for the long lifespan of cast iron pipes is their inherent durability. Cast iron is a strong material that can withstand high levels of pressure, temperature changes, and physical impacts. It is also resistant to fire and has excellent sound-dampening properties, making it a reliable choice for sewage and drainage systems in buildings.

However, the lifespan of cast iron pipes can be influenced by external factors. Environmental conditions, such as soil acidity and moisture levels, can accelerate the deterioration of the pipes. Corrosion is another common issue that can affect cast iron plumbing, particularly in areas with aggressive water or chemical content. If not addressed promptly, corrosion can lead to leaks, blockages, and ultimately the failure of the plumbing system.

Can cast iron pipes last longer than 100 years?

There is some difference when it comes to assessing the life span of cast iron sewer pipes since more conservative estimates peg the range at anywhere from 50 to 65 years. More optimistic sources bump those numbers up to roughly 75 years, with some lasting a full century.

Yes, cast iron pipes have the potential to last longer than 100 years with proper installation, maintenance, and favorable environmental conditions. While there are numerous factors that can affect the lifespan of cast iron plumbing, the material’s inherent durability and resistance to corrosion make it capable of withstanding the test of time.

When installed correctly, cast iron pipes can provide long-lasting performance for sewage and drainage systems in residential, commercial, and industrial settings. The material’s ability to withstand high pressure, temperature fluctuations, and physical impact contributes to its longevity. Additionally, cast iron’s resistance to rust and corrosion helps protect the pipes from internal and external deterioration.

However, it’s important to note that the lifespan of cast iron pipes can vary depending on several factors. Environmental conditions, such as soil acidity, moisture levels, and chemical exposure, can accelerate corrosion and reduce the lifespan of the pipes. Furthermore, poor installation practices, lack of maintenance, and neglecting timely repairs can also contribute to premature deterioration.

What eats cast iron pipes?

Tuberculation forms along the pipe wall due to iron-oxidizing bacteria found in the water. The bacteria congregate in water lines and begin to metabolize the cast iron pipes.

Cast iron pipes are generally resistant to being consumed or eaten by living organisms. However, there are a few factors that can contribute to the degradation or deterioration of cast iron pipes over time. These factors include:

Corrosion

Corrosion is a chemical process that can gradually eat away at the surface of cast iron pipes. It is typically caused by the reaction between the iron in the pipes and elements in the surrounding environment, such as oxygen and moisture. Corrosion can weaken the pipes and lead to leaks or structural damage.

Soil Acidity

If the soil surrounding the cast iron pipes has high acidity levels, it can accelerate the corrosion process. Acidic soil can corrode the protective layer of the pipe, making it more vulnerable to deterioration.

Chemical Drain Cleaners

Harsh chemical drain cleaners, if used regularly, can potentially damage cast iron pipes. These cleaners contain strong acids or alkalis that can corrode or weaken the pipe material over time.

Why does cast iron pipe crack?

One is the crack that you describe, usually forming on top of the pipe or at a seam, created by the form used during the casting process. This is likely due to the hydrogen sulfide gas collecting in concentration and the resulting acidic attack weakening the pipe wall.

Cast iron pipes can crack for several reasons, and understanding these factors can help in preventing or addressing the issue. Here are some common causes of cast iron pipe cracking:

Corrosion

Corrosion is one of the primary reasons for cast iron pipe cracking. Over time, exposure to moisture and certain chemicals in wastewater can lead to the formation of rust and corrosion on the interior and exterior surfaces of the pipe. This corrosion weakens the structural integrity of the pipe, making it susceptible to cracking under pressure.

Age and Wear

Cast iron pipes have a long lifespan, but they can eventually deteriorate with age. The constant flow of wastewater, along with natural wear and tear, can gradually weaken the pipe material. Over time, this weakening can lead to cracks and fractures, especially in areas where the pipe is exposed to higher levels of stress or impact.

Soil Movement

Changes in the surrounding soil can put stress on cast iron pipes and cause them to crack. Shifting or settling of the soil due to factors like ground movement, construction activities, or changes in moisture levels can exert pressure on the pipes. This can result in cracks or even complete pipe failure.

Poor Installation or Support

Improper installation practices, such as inadequate support or misaligned joints, can create stress points in cast iron pipes. These stress points can lead to cracking over time, especially when the pipes are subjected to pressure or movement.

Freezing Temperatures

In regions with cold climates, freezing temperatures can cause water inside cast iron pipes to expand, leading to pipe cracks or bursts. This is particularly common when the pipes are not adequately insulated or protected from freezing conditions.

What factors can affect the lifespan of cast iron plumbing?

Several factors can influence the lifespan of cast iron plumbing. These include the quality of the installation, the type and frequency of use, the presence of corrosive substances in the water, and the level of maintenance and upkeep. Harsh chemicals, abrasive materials, and excessive wear and tear can contribute to the deterioration of cast iron pipes over time.

Several factors can affect the lifespan of cast iron plumbing. These include:

Environmental Conditions

The environment in which the cast iron pipes are installed can have a significant impact on their longevity. Factors such as soil acidity, moisture levels, and the presence of chemicals or corrosive substances in the surrounding soil can accelerate the deterioration of the pipes. Harsh environmental conditions can cause the cast iron to corrode more rapidly, shortening its lifespan.

Water Quality

The quality of the water running through the cast iron pipes can also affect their lifespan. High levels of acidity or alkalinity in the water, as well as the presence of minerals and contaminants, can contribute to corrosion and rust formation. Over time, this can weaken the pipes and lead to leaks or structural damage.

Installation Quality

The quality of the initial installation plays a crucial role in determining the lifespan of cast iron plumbing. Improper installation techniques, such as inadequate support or poorly sealed joints, can create weak points in the system. These weak points are more prone to leaks, corrosion, and eventual failure. Proper installation practices, including ensuring secure connections and appropriate support, can help extend the lifespan of the plumbing system.

How can I extend the lifespan of cast iron plumbing?

To extend the lifespan of cast iron plumbing, regular inspection and maintenance are crucial. This includes checking for signs of corrosion, leaks, or damage, and addressing them promptly. Keeping drains clear and avoiding the disposal of harmful substances down the drains can also help prevent clogs and minimize the strain on the pipes. Additionally, applying protective coatings or linings to the pipes, as well as periodically flushing the system, can provide additional protection and help prolong their lifespan.

To extend the lifespan of cast iron plumbing, there are several key steps you can take:

Regular inspections and maintenance

Schedule routine inspections of your plumbing system to identify any signs of corrosion, leaks, or blockages. Early detection and prompt repairs can prevent further damage and extend the lifespan of the pipes. Regular maintenance should include cleaning out debris and ensuring proper water flow.

Control water acidity

High levels of acidity in water can accelerate the corrosion of cast iron pipes. Test your water periodically and, if necessary, install a water treatment system to adjust the pH levels and reduce acidity. This can help protect the pipes from premature deterioration.

Prevent pipe clogs

Avoid disposing of materials that can cause clogs and blockages in your plumbing system. This includes grease, oils, food scraps, and non-flushable items like wipes and sanitary products. Using drain strainers or screens can help trap debris and prevent it from entering the pipes.

What are common signs of deterioration in cast iron plumbing?

Signs of deterioration in cast iron plumbing may include the presence of rust or corrosion on the pipes, leaks or water stains, foul odors, frequent clogs or slow drains, and a decrease in water pressure. If you notice any of these signs, it’s important to have the plumbing system inspected by a professional to assess the extent of the damage and determine the necessary repairs or replacements.

Common signs of deterioration in cast iron plumbing include:

Corrosion

One of the primary indicators of cast iron plumbing deterioration is the presence of corrosion. Over time, exposure to water and wastewater can cause the interior and exterior surfaces of the pipes to corrode. Signs of corrosion include reddish or orange-brown stains on the pipes, flaking or scaling of the metal, and rough textures on the pipe surfaces.

Leaks and Water Damage

Deteriorating cast iron pipes are prone to developing leaks. These leaks can manifest as dripping or pooling water around the plumbing fixtures, damp spots on walls or ceilings, or unexplained increases in water bills. Water damage, such as mold growth, rotting wood, or discoloration of building materials, may also indicate deteriorating cast iron plumbing.

Blockages and Reduced Water Flow

Over time, cast iron pipes can accumulate mineral deposits, rust, and debris, leading to blockages and reduced water flow. Slow-draining sinks, toilets, or showers, gurgling noises in the plumbing system, or recurring clogs are common signs of deteriorating cast iron plumbing. These blockages can occur due to the corrosion and scaling of the pipes, hindering the smooth flow of wastewater.

Conclusion

Cast iron plumbing has a reputation for being durable and long-lasting. With proper installation and maintenance, cast iron pipes can have a lifespan of up to 100 years or more. The material’s strength and resistance to corrosion make it an excellent choice for sewage and drainage systems in both residential and commercial buildings.

However, it’s important to note that the lifespan of cast iron plumbing can be influenced by various factors. Environmental conditions, such as soil acidity and moisture levels, can accelerate the deterioration of cast iron pipes. Additionally, the quality of installation and maintenance practices play a significant role in determining the longevity of the plumbing system.

To maximize the lifespan of cast iron plumbing, regular inspections and maintenance are crucial. This includes checking for signs of corrosion, leaks, and blockages, as well as addressing any issues promptly. Over time, it may be necessary to repair or replace sections of cast iron pipes if they become compromised. By following these guidelines and taking proactive measures, property owners can ensure the extended durability of their cast iron plumbing system.