When Was Cast Iron Plumbing Used

Introduction

When Was Cast Iron Plumbing Used: Cast iron plumbing has a long and storied history, with its usage dating back several centuries. The earliest evidence of cast iron being used in plumbing systems can be traced back to ancient civilizations, including the Roman Empire and ancient China. However, it wasn’t until the 18th century that cast iron plumbing became widely adopted in Europe and North America, revolutionizing the way water and waste were managed in urban areas.

During the Industrial Revolution, the rapid growth of cities and the increasing demand for water supply and sanitation necessitated the development of more efficient plumbing materials. Cast iron emerged as a superior option due to its durability, strength, and resistance to corrosion. The manufacturing process involved melting iron and pouring it into molds, creating sturdy pipes that could withstand the pressure and stresses of water damage plumbing distribution and waste disposal systems.

Cast iron plumbing dominated sewer lines, drainage systems, and water distribution networks in the 19th and early 20th centuries. It was used in residential, commercial, and industrial applications due to its reliability and durability. In older buildings, especially metropolitan ones, cast iron pipes were used to meet the needs of growing populations and infrastructure.

How old is cast iron pipe?

Versailles got its first cast iron pipes in 1664. In the 1810s, Philadelphia erected the first cast iron pipes to replace deteriorating spruce log pipes.

Ancient Romans, recognized for their outstanding engineering and infrastructure, pioneered cast iron water distribution and drainage pipes. They built a complex network of aqueducts and sewers, with cast iron pipes going back to the 3rd century BCE. Early pipes were manufactured by pouring molten iron into molds to create strong cylindrical tubes.

Ancient China also valued cast iron pipes. China used cast iron pipes in its plumbing infrastructure in the 4th century BCE Warring States period. These pipes irrigated, drained, and supplied cities and farms with water.

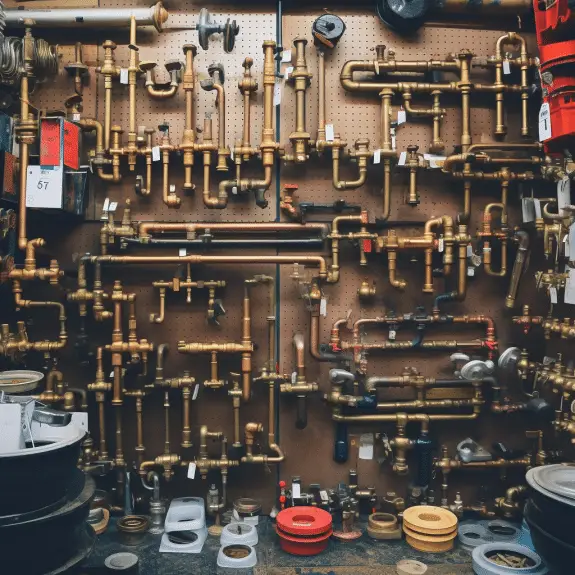

Cast iron pipe

Cast iron plumbing wasn’t widespread in Europe and North America until the 18th century. Industrialization accelerated urbanization, increasing water and sanitation needs. The strength, durability, and corrosion resistance of cast iron made it suitable.

The 19th and early 20th centuries saw cast iron pipes dominate sewer, drainage, and water distribution networks. Residential, commercial, and industrial use in cities. Many antique buildings have cast iron pipes.

Cast iron pipe ages vary greatly. Maintenance, installation, and production quality affect cast iron pipe longevity. Well-maintained cast iron pipes endure 100 years.

Is cast iron still used for plumbing?

Pre-1970s (early 1980s) residences had iron pipes. Builders praised cast iron pipes’ toughness, water resistance, and damage resistance. Residential installations are fewer.

Plumbing requires less cast iron due to copper, PVC, PEX, and other alloys. These materials are cheap, corrosion-resistant, and easy to install. Plumbing uses copper pipes for durability and versatility. Plumbing uses plastic pipes often. PVC and PEX pipes are lightweight, flexible, corrosion- and chemical-resistant. They install faster and easier than cast iron.

Plumbing cast iron rust destroys it. Cast iron can rust and scale if ignored, despite its corrosion resistance. Leaky cast iron pipes are expensive to repair and replace.

Despite these issues, cast iron pipes are used occasionally. Older buildings may have cast iron sewer and drainage lines. Pipes may still work. Maintenance and inspections are needed for continuous operation.

Are cast iron pipes a problem?

Pre-1975 homes may contain cast iron pipes. Rusty cast iron pipes weaken. About 76 million US homes need cast iron pipe replacement. Mineral deposits and scale can form inside cast iron pipes. Buildup blocks and lowers water pressure. Scale’s uneven surface collects dirt and clogs.

Support is needed for cast iron pipe installation. Plumbing rehabilitation and retrofitting are complicated by pipe weight. Handling, transit, and collisions make cast iron more fragile. Cast iron pipes that crack may need immediate repair or replacement. Plastic and copper pipes are more flexible than cast iron. Installation in narrow spaces and around obstacles is challenging due to stiffness. Installation may take longer than flexible options.

Not all cast-iron pipes last. Poor installation, maintenance, and harsh environments limit cast iron pipe life. Repairing or replacing these pipes is expensive and difficult.

Is cast iron better than PVC?

Fireproof cast iron and PVC. PVC melts in house fires due to its 450-degree self-ignition. Heat-resistant iron pipes won’t melt. PVC is cheaper than cast iron. Transporting and installing lightweight PVC is cheaper and easier. Heavy cast iron pipes require more labor to install, raising material and labor costs. Over time, cast iron pipes’ durability can exceed their cost.

Installing PVC pipes is easy because they are lightweight and can be linked using solvent welding or mechanical connections. The flexibility of PVC makes small spaces easier to navigate. Stiff iron pipes need careful handling and support during installation. Installing heavy items takes additional labor and equipment.

PVC pipes are adaptable because they resist corrosion. Poorly maintained cast iron pipes rust and scale. Regularly cleaning and lining cast iron pipes reduces corrosion.

Cast iron pipes naturally reduce water flow noise and vibration. They help residential structures reduce noise. PVC pipes are lightweight and stiff, making them noisier. Insulation and soundproofing reduce noise.

How do I know if my plumbing is cast iron?

If you locate the pipes in this area and notice that they have a black finish along with a bulge at each section, then you know that you have cast iron plumbing. Keep in mind, though, that these pipes can corrode and the black finish might get a rusty hue.

Visual Inspection: Examine any exposed pipes in your basement, crawl space, or utility areas. Cast iron pipes have a distinctive appearance, often characterized by a rough, textured surface with a dull gray or black color. They may also display signs of rust or scaling, especially in older systems.

Pipe Diameter: Cast iron pipes typically have a larger diameter compared to modern materials like PVC or copper. If you can access a section of the pipe, measure its diameter. If it exceeds 3 or 4 inches, it is more likely to be cast iron.

Magnet Test: Cast iron is a ferrous metal, which means it is magnetic. Use a magnet and see if it sticks to the pipe. If the magnet attaches firmly, it suggests that the pipe is made of cast iron. However, be cautious, as some modern materials may have a thin layer of metal coating that can also attract magnets.

Professional Inspection: If you are unsure about the material of your plumbing system, it is best to consult a licensed plumber or a plumbing professional. They have the expertise and tools to accurately identify the type of pipes used in your plumbing system. They may perform tests, use inspection cameras, or analyze pipe samples to determine the material.

Historic Records or Building Documentation: If available, consult any documentation or records related to your property’s plumbing system. Blueprints, building permits, or maintenance records may provide information on the type of pipes used during construction or subsequent renovations.

Why use cast iron pipe for plumbing?

Strength and Durability

Heavy weights don’t deflect cast iron pipes, making them strong. It is perfect for trenchless pipe lining and underground drainage. Cast-iron pipes resist corrosion. They can withstand soil, water, and sewage corrosion if protected. This resistance prevents leaks and maintains piping.

Fireproof cast iron pipes are non-combustible. High-temperature cast iron pipes prevent fires and plumbing damage. Due to their weight and density, cast iron pipes reduce sound. This reduces water flow noise, which is important in homes.

Plumbing water stays warm using cast iron pipes. Insulation decreases heat loss and improves hot water distribution energy efficiency. Cast iron is eco-friendly and recyclable. Melting and recycling cast iron pipes saves resources.

Where are cast iron pipes used?

Cast Iron Pipe Meaning Before plastic pipes, CI pipes carried water and sewage. Construction drainage systems remove rainwater and wastewater with cast iron pipes. Due to their endurance, they can withstand water pressure and flow in commercial and industrial settings.

Heavy-duty industrial plumbing uses cast iron pipes. Manufacturing, chemical processing, and power production use cast iron pipes because they resist high temperatures, pressure, and corrosion.

Properties built before the mid-20th century may include cast iron plumbing pipes. Cast iron pipes are durable enough to endure in historical buildings.

Older cities and urban areas use cast iron pipes for water distribution. They deliver clean water to households, companies, and industries.

Why use cast iron pipe for plumbing?

Strength and Durability

Cast iron is a strong piping material because it doesn’t deflect under heavy loads. Therefore, it makes for an excellent choice for underground drainage installations and trenchless pipe lining services.

Corrosion Resistance: Cast iron pipes possess inherent resistance to corrosion. When properly protected, they can withstand the effects of corrosive elements present in soil, water, and sewage. This resistance reduces the risk of leaks and maintains the integrity of the plumbing system over time.

Sound Dampening: Cast iron pipes have natural sound-dampening properties due to their weight and dense composition.

Fire Resistance: Cast iron is a non-combustible material, making cast iron pipes highly resistant to fire. In the event of a fire, cast iron pipes can withstand high temperatures, limiting the spread of flames and minimizing damage to the plumbing system.

Environmental Considerations: Cast iron is a recyclable material, making it an environmentally friendly choice. As a result, cast iron plumbing became less common in new construction projects. Nonetheless, the impact of cast iron plumbing should not be underestimated.

Conclusion

While cast iron plumbing has been gradually replaced by newer materials in modern construction, its legacy endures in many structures that still rely on the robustness and longevity of these pipes. The utilization of cast iron pipes showcases the ingenuity and innovation of past generations in addressing the challenges of managing water and waste.

The advent of new materials, such as copper, plastic, and PVC, brought about advancements in plumbing technology, offering cost-effective, easier-to-install, and corrosion-resistant alternatives to cast iron. These materials have become the standard choice for contemporary plumbing systems. While cast iron plumbing enjoyed decades of success, its usage gradually declined in the mid-20th century with the emergence of new materials such as copper, plastic, and PVC.

These materials offered advantages in terms of cost, ease of installation, and resistance to corrosion. As a result, cast iron plumbing became less common in new construction projects. Nonetheless, the impact of cast iron plumbing should not be underestimated. It paved the way for the development of more efficient plumbing solutions, enabling the expansion of cities, improved public health, and better living conditions for millions of people.