What Is A Wet Vent Plumbing

Introduction

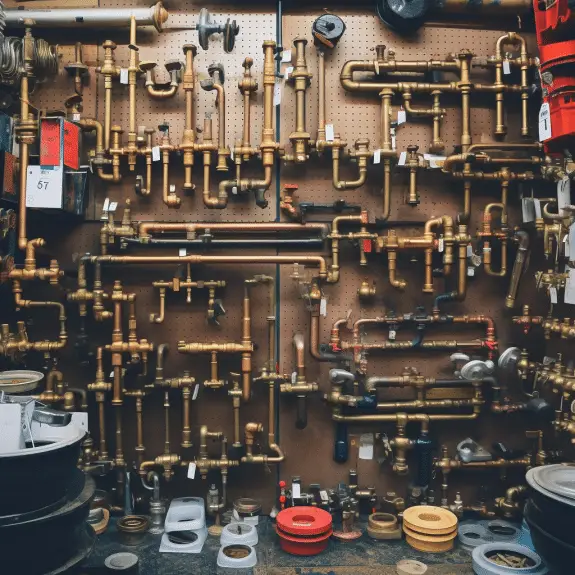

What Is A Wet Vent Plumbing: Plumbing systems have separate pipes for drainage and ventilation. Drain pipes carry waste and wastewater away from fixtures such as toilets, sinks, and showers, while vent pipes provide a means for proper air circulation within the system, preventing negative pressure, siphoning, and odors. However, in a wet vent system, a single pipe serves both purposes concurrently, eliminating the need for separate vent pipes.

The concept behind wet venting is to utilize the water flow in a drainage pipe to house plumbing a natural ventilation effect. As water moves through the pipe, it pushes air ahead of it, creating positive pressure that helps draw air from other fixtures and vent the system. This arrangement simplifies the plumbing layout, reduces the number of pipes needed, and streamlines the installation process.

Wet vent plumbing systems are commonly found in residential and commercial buildings, particularly where space is limited or in situations where the plumbing layout requires a more efficient use of resources. By combining drainage and ventilation functions in a single pipe, it becomes possible to design more compact and flexible plumbing systems, saving both time and money during installation.

What is an example of a wet vent?

Wet venting is most prevalent with toilets and sinks, where the sink drain is also the toilet vent. Let’s examine this bathroom’s moist vent system. Waste and wastewater from all fixtures flow down the toilet’s main drain pipe. Air flows ahead of water and waste as they move down the toilet drain pipe under positive pressure.

The wet vent pipe drains the sink and bathtub and vents the drainage system. Wet vent systems allow for more compact and efficient bathroom plumbing. Wet vent pipes handle drainage and ventilation, saving space and reducing the number of pipes needed. This is useful in smaller bathrooms or buildings with restricted plumbing.

What is a dry vent pipe?

For any bathroom group fixture except an emergency floor drain, the dry vent, which continues upward from the wet vent to the termination of connection to another vent, must be either individual or common.

A dry vent pipe lets air into the drainage system to prevent airlock and siphoning. It allows sewer gasses to escape into the atmosphere rather than gathering in the plumbing system or returning into the structure.

Dry vent pipes preserve plumbing system efficiency by allowing fresh air to enter and balance drainage pipe pressure.

Dry vent pipes must be carefully placed and sized. To guarantee effective ventilation, building codes set minimum diameter and maximum distance between fixtures and vent pipes. Maintaining system integrity and preventing leaks requires proper vent elbow and vent flashing installation.

What is the purpose of a wet vent?

A wet vent is officially defined as a pipe serving simultaneously as a waste pipe and vent. Also, the wet vent protects the drain’s trap for other fixtures connected to the system. If you are not aware, every bathroom fixture needs venting.

Wet vents allow wastewater and sewage to flow properly while venting to prevent negative pressure, siphoning, and sewer gas buildup. Wet vent systems simplify plumbing and save resources by integrating both tasks in one pipe.

Water and waste run down a wet vent system’s drainage pipe, creating positive pressure that pushes air ahead. Positive pressure draws air from other fixtures and vents the system, eliminating vent pipes.

The wet vent pipe drains and vents. It transports effluent from toilets, sinks, and showers and allows airflow. This configuration reduces pipes and optimizes space, simplifying plumbing layout.

In small spaces or when resource efficiency is sought, a moist vent system is beneficial. This plumbing system simplifies installation and saves money for residential and commercial structures.

What size is a wet vent pipe?

The fixture unit discharge into the wet vent determines its size. For 4 drainage fixture units (dfu) or less, the wet vent must be 2 inches (50 mm) in diameter, and for 5 or more, 3 inches (80 mm).

A wet vent pipe’s diameter depends on the TFUs it serves. A fixture’s load on the plumbing system is measured in fixture units. Fixture unit values vary by fixture type, size, and expected use.

The IPC and other plumbing codes provide guidelines and tables to calculate wet vent pipe size depending on fixture units. These tables show the minimum wet vent pipe diameter based on the number and kind of fixtures.

Some plumbing rules require a 2 inch (51 mm) wet vent pipe for a single toilet and one or two other fixtures like a sink or bathtub. However, wet vent pipe diameter may grow with fixture count and fixture unit load.

What is the angle of a wet vent?

All horizontal wet vents must have 45-degree drain pipe connections. Our wet vent pipe size must match the fixtures’ maximum load.

Wet vent pipe slope requirements are commonly specified in the International Plumbing Code (IPC) and other plumbing codes. The minimum slope for drainage is usually represented as a vertical rise to horizontal run ratio in these rules.

A minimum slope of 1/4 inch per foot (20.8 mm/m) is recommended for horizontal drainage pipes, including wet vent pipes. This slope keeps wastewater flowing and prevents pipe flooding.

A moist vent pipe that stretches horizontally 10 feet (3 meters) must have a minimum slope of 2.5 inches (64 mm) for drainage. This slope lets wastewater flow downhill with gravity, preventing pipe buildup.

Plumbing rules may also limit maximum slope to prevent excessive flow rates, noise, or pressure imbalances. Maximum slope limits vary by plumbing code and pipe diameter.

Wet vent pipe slope requirements must be determined by consulting the project’s local plumbing code or a trained plumber. During installation, consider pipe diameter, flow rates, and plumbing system layout.

Can you wet vent a shower?

In a wet vent system, as water and waste flow down the drainage pipe from the shower, they create positive pressure that pushes air ahead of them. This positive pressure helps draw air from other fixtures connected to the wet vent, effectively venting the entire plumbing system.

When wet venting a shower, the wet vent pipe will typically serve other fixtures as well. For example, the wet vent pipe may also connect to the drain of a nearby sink or toilet. The combined flow of wastewater and air from these fixtures helps maintain proper drainage and ventilation within the plumbing system.

It is important to note that wet venting a shower, or any other fixture, must comply with local building codes and regulations. Building codes may specify the maximum distance between fixtures, the minimum pipe diameter, and other requirements to ensure proper ventilation, drainage, and compliance with plumbing standards.

Careful planning and design are crucial when wet venting a shower. Adhering to the requirements outlined in the plumbing codes and consulting with a qualified plumbing professional can ensure the effective and safe wet venting of a shower.

What is the difference between a wet vent and a common vent?

Wet vent systems drain water from one fixture and vent air from others. A dry vent system moves air only. Vents can vent one fixture and drain another, while dry vents normally vent one fixture.

Wet Vent: A wet vent uses one pipe to drain and ventilate many fixtures. Systems vent the plumbing system by pushing air ahead of the drainage pipe due to positive pressure.

Wet venting simplifies plumbing arrangement and reduces pipe count, its main benefit. Venting maximizes space usage, lowers material and installation costs, and streamlines the plumbing system by integrating drainage and ventilation.

A common vent is a plumbing system where many fixtures share a vent pipe for ventilation. A common vent does not convey wastewater or drain like wet venting. The vent pipe allows air to enter and exit the plumbing system, preventing negative pressure, siphoning, and sewage gas buildup.

The fundamental benefit of a shared vent system is efficient ventilation without fixture-specific vent pipes.

What are the requirements for a wet vent?

The wet vent shall be not less than 2 inches in diameter for 4 drainage fixture units (DFU) or less, and not less than 3 inches in diameter for 5 DFU or more.

Fixture Unit Load: The total fixture unit load determines the sizing and capacity of the wet vent pipe. Fixture units represent the load or demand that each fixture places on the plumbing system. The local plumbing code will provide guidelines on the minimum pipe diameter and maximum fixture units allowed for wet venting.

Vent Pipe Size and Placement: The diameter and placement of the wet vent pipe must adhere to code requirements. Building codes often specify the minimum pipe diameter based on the number and types of fixtures connected to the wet vent system.

Slope and Drainage: Proper slope is critical for effective drainage in a wet vent system.

Venting Requirements: Wet venting must provide adequate ventilation to prevent negative pressure, siphoning, and sewer gas buildup. The local plumbing code will outline the requirements for venting, including the maximum distance between fixtures and the vent pipe, the positioning of vent fittings, and the number and type of vents required for the wet vent system.

Conclusion

A wet vent plumbing system is a unique configuration that combines drainage and ventilation functions within a single pipe. By leveraging the water flow in the drainage pipe, the system creates a natural ventilation effect, eliminating the need for separate vent pipes. This innovative approach simplifies plumbing layouts, reduces installation complexity, and optimizes space utilization.

The advantages of wet vent plumbing systems make them particularly beneficial in situations where space is limited or where a more efficient use of resources is desired. Residential and commercial buildings can benefit from the streamlined installation process and cost savings associated with this type of plumbing system.

Careful planning and design are essential to ensure the system functions effectively and meets all necessary requirements. Overall, wet vent plumbing systems offer a practical and efficient solution for integrating drainage and ventilation functions in plumbing setups. With proper implementation and adherence to regulations, this approach can contribute to the smooth and reliable operation of plumbing systems in various settings.