What Is A Riser In Plumbing

Introduction

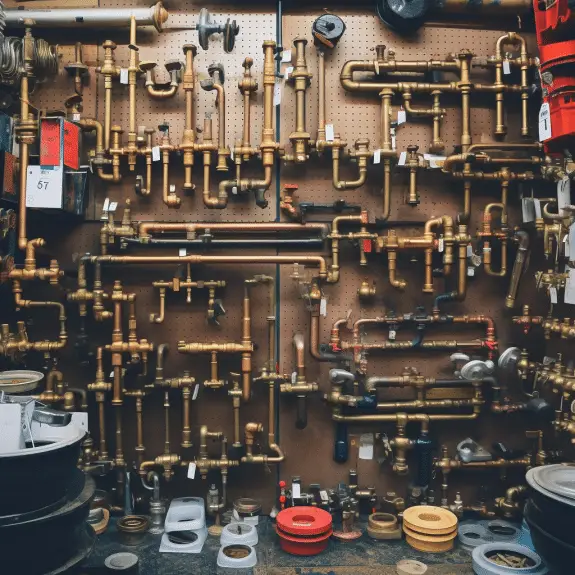

In the realm of plumbing systems, numerous components work together to ensure the smooth functioning of water supply and drainage. Among these components, a riser holds a crucial role in directing water flow vertically within a building or structure. A riser in plumbing pipe refers to a vertical pipe or conduit that connects different floors or levels, allowing the movement of water or other fluids between them.

The primary purpose of a riser is to facilitate the vertical movement of water or sewage from one level to another. For instance, in multi-story buildings, a riser serves as a conduit for water supply, enabling water to reach upper floors efficiently. In addition to their functional purpose, risers often incorporate additional features to enhance their safety and accessibility. For instance, they may include shut-off valves or isolation valves at different levels, allowing for individual control and maintenance of water supply.

What Is Riser In Plumbing?

Up and down pipes bring fresh water from the bottom to the upper floors.

Vertical pipes move liquid like water, gas, and other substances from one level of a building to another. It helps the piping system move water around and get rid of waste. With valves and links, risers control the flow of fluids to bring water to the surface and remove waste.

Risers get rid of water and garbage from buildings with more than one floor. They connect the plumbing and equipment on each floor to the main water and waste lines.

Walls or shafts hide the risers. It has branch lines that link to horizontal pipes on each floor. This lets trash or water rise. Build rules in your area decide whether to use copper, PVC, or cast iron riser lines.

What Is Riser Means In Drilling?

A drilling riser temporarily connects a subsea oil well to a surface drilling facility.

Risers are essential offshore drilling components. A large-diameter pipe connects the drilling rig on the water’s surface to the wellhead on the seafloor. The riser transports drilling fluids like mud and cuttings between the surface and the wellbore.

A riser in drilling is used to push drilling fluids down the wellbore and return cuttings and other items to the surface. Drilling fluid circulation cools and lubricates the drill bit, stabilizes the wellbore, and transports cuttings to the surface.

What Is Bathroom Riser?

A elevated toilet seat is a simple device that raises a toilet bowl. Older persons who have problems sitting in toilet-like seats utilize them. The most common toilet seat riser heights are 2 to 6 inches.

A bathroom riser is a plumbing system that raises bathroom fixtures like toilets and sinks for people with special needs or mobility issues. Risers make standard-height bathroom fixtures more accessible and pleasant for persons who have trouble using them.

Bath risers lift fixtures to make them easier for those with mobility issues to use without bending or straining. Disability, elderly, and post-surgery patients may benefit from this.

Toilets often have bathroom risers fitted between the base and seat to raise the seat. This modification can help disabled toilet users sit and stand.

What Is The Difference Between Riser And Pipeline?

Risers are vertical or near-vertical pipes that connect above-water facilities to an underwater pipeline. According to rules, the riser part must run from the first above-water valve or isolation flange to five pipe diameters beyond the bottom elbow.

Commonly used in fluid transportation, “riser” and “pipeline” refer to separate components and have different tasks.

A riser is a vertical pipe or conduit that efficiently distributes fluids like water or gas between building levels. Plumbing systems use risers to move fluids between floors. They can serve upper floors with water or remove garbage. Risers have valves and fittings to manage fluid flow and isolate or maintain floors or portions.

However, a pipeline is a large network of pipes that transfer oil, gas, or water over great distances. They can be underground, underwater, or above ground and span hundreds or thousands of kilometers.

What Is Riser Size?

Riser size affects fluid capacity and flow rate. Plumbing riser sizes depend on use and building codes. Water supply line risers for residential structures are usually 3/4″ or 1″, but bigger commercial buildings may need 1 1/4″ or 1 1/2″. A plumbing riser’s size depends on the water demand of fixtures on different floors and the pressure needed for flow.

The diameter of the pipe connecting the drilling rig to the undersea wellhead is called riser size. Offshore drilling risers are 18–21 inches or larger than plumbing risers. Drilling fluids and equipment pass through the wider diameter during offshore drilling.

What Is The Advantage Of Riser?

Besides burning calories, a standing desk riser can reduce blood sugar. Studies show that standing for lengthy durations reduces blood sugar rises by 43% more than sitting.

Using risers in numerous applications improves fluid transport system efficiency and effectiveness. Key riser benefits include:

Risers make it easier to supply water to upper floors and remove garbage from them. Risers improve plumbing system functionality by connecting building floors for easy water and drainage access.

This ensures appropriate supply and pressure for fixtures and appliances by efficiently and evenly distributing resources to floors or regions.

Flexibility and Modularity: Risers are modular, making installation, replacement, and reconfiguration straightforward. Their modular design facilitates quick plumbing or fluid transport system changes to meet changing needs.

System Isolation and Maintenance: Risers have valves and fittings to isolate floors or parts of a structure. This function permits floor or section shutdowns without interrupting the system, which is useful during maintenance or repair.

Safety and Security: Risers protect wellbore integrity and prevent fluid or gas escape during drilling. Risers improve drilling safety by allowing fluid circulation and supporting safety equipment like blowout preventers (BOPs).

Where Are Risers Commonly Used In Plumbing?

Risers are frequent in multi-story buildings including flats, offices, hotels, and businesses. Water supply and drainage connections to different floors are necessary for a building-wide plumbing system.

Plumbing systems that convey water or waste vertically employ risers. Common plumbing riser uses include:

Multistory Buildings: Risers deliver water and remove garbage from upper floors in multistory buildings. They ensure continuous water flow and effective waste disposal by connecting major water supply and drainage lines to floor fixtures and appliances.

Risers supply water to upper-level apartments and condominiums in high-rise residential structures. They ensure enough water pressure and supply to each apartment or condominium unit by efficiently distributing water to numerous floors.

Office complexes, shopping malls, hotels, hospitals, and other commercial facilities use risers to deliver water and manage trash on multiple levels. Risers allow water to reach restrooms, kitchens, and utility rooms while ensuring effective drainage.

High-Efficiency Plumbing Systems: Green buildings and those following water conservation regulations may use risers to optimize water usage and reduce energy consumption.

How Is A Riser Different From A Regular Pipe?

Risers and conventional pipes transport fluids in a plumbing system, but their direction differs. Riser pipes connect levels vertically, while normal pipes deliver water horizontally or at an angle.

Risers and normal pipes serve different purposes and contexts. Risers differ from normal pipes in these ways:

Vertical or horizontal installation is a major difference. A riser is a vertical conduit that connects building floors to transfer fluids vertically. Alternatively, a horizontal pipe transports fluids in a system.

Risers are used in plumbing systems to give water to upper floors or remove garbage. They ensure effective building fluid distribution. In irrigation systems, water supply networks, and industrial pipelines, regular pipes transfer fluids over larger distances.

Size and Design: Risers are usually smaller than pipes. Riser size depends on the application and building codes. Regular pipes, especially those for long-distance fluid transfer, can handle higher flow rates and pressures and have bigger diameters.

Regular pipes are visible and accessible for inspection, maintenance, and repair.

How Are Risers Connected To The Plumbing System?

The process of connecting risers to the plumbing system involves several steps:

Design and Planning:

The connection of risers starts with careful design and planning of the plumbing system.

Branch Line Connection:

Risers are typically connected to the main supply or drainage lines through branch lines. These branch lines extend horizontally from the main lines to the desired location of the riser. The connection is made using appropriate fittings, such as tees or elbows, ensuring a secure and watertight joint.

Valve Installation:

Valves are installed on the riser at each floor or level to control the flow of water or waste. These valves allow for the isolation of specific floors or sections of the plumbing system during maintenance or repair work.

Fixture Connection:

Once the riser is in place, the fixtures or appliances on each floor are connected to the riser through appropriate fittings. These fittings may include pipes, connectors, or flexible hoses depending on the specific fixture and building codes.

Testing and Inspection:

After the risers and fixtures are connected, the plumbing system is thoroughly tested for leaks and proper flow. This includes conducting pressure tests and inspecting connections and joints to ensure they meet the required standards.

Conclusion

A riser in plumbing serves as a vital component in facilitating the vertical movement of water and sewage within a building or structure. Its primary function is to connect different levels or floors, enabling the efficient supply of water and the proper disposal of wastewater. By understanding the role and characteristics of risers, plumbers, construction professionals, and homeowners can ensure the effective design, installation, and maintenance of plumbing systems.

Risers are constructed using durable materials such as copper, PVC, or cast iron, ensuring their ability to withstand the pressure and load of water or waste flowing through them. They are often equipped with shut-off valves or isolation valves at various levels, allowing for individual control and maintenance of water supply. Concealed within walls or other enclosed spaces, risers also contribute to the aesthetic appeal of a building.

The importance of risers extends beyond functionality. They play a crucial role in ensuring the safety and convenience of occupants by providing uninterrupted water supply to upper floors and facilitating the efficient disposal of wastewater. Properly designed and maintained risers contribute to the overall efficiency and longevity of plumbing systems, minimizing the risk of leaks, blockages, or other plumbing issues.