What Is A Check Valve In Plumbing

Introduction

A plumbing check valve allows fluid to flow in one direction while preventing it from reversing. It is necessary for plumbing system integrity and functionality.

Check valves automatically open and close based on fluid flow. It uses pressure differentials. When incoming fluid pressure exceeds output pressure, the valve opens, letting fluid through. When outlet pressure rises, the valve closes, blocking fluid flow backward.

Check valves are frequently used in plumbing to avoid fluid backflow. When flow reverses, backflow can contaminate potable water with non-potable water or other pollutants. Rapid pressure shifts, such as when an appliance siphons water back into the supply line or during water supply outages, can cause this.

The installation of check valves at critical points within a plumbing system helps safeguard against these backflow incidents. They are commonly found in various applications, including residential house plumbing, commercial buildings, industrial facilities, and municipal water supply networks.

What Is The Purpose Of A Check Valve In Plumbing?

To protect pipes, other valves, pumps, and other things, a check valve is a one-way valve that shuts off if the flow changes direction.

Check valves in plumbing stop overflow and keep the system working properly. It can contaminate drinking water or damage plumbing systems. A check valve lets fluid run in one direction but stops it from flowing in the other direction on its own.

Check valves keep dirty water from getting into drinkable water. A sudden drop in the water flow in the city can create a vacuum that pulls water or chemicals back into the supply line from appliances or pipes. A check valve at key points in the plumbing system stops this backflow and makes sure that only clean, drinkable water runs.

A check valve also keeps the water system working well and reliably. It stops fluids from running backwards and keeps them moving forward, so water or other fluids can get where they need to go without any problems.

Where Should A Check Valve Be Installed?

A well’s second check valve should be 25 feet above the pump.

The main water supply line must have a check valve near the building’s main entrance. This prevents appliance or system backflow into municipal water supplies, preventing pollution.

Toilet, dishwasher, washing machine, and irrigation lines employ check valves.

Pump-powered plumbing systems commonly have an outlet-side check valve. It prevents backflow when the pump is off, maintaining pressure and reducing damage.

Branch lines and risers may have cross-connections or tainted water, thus check valves are installed. Fluid- or chemical-using commercial and industrial environments require this.

Underground or exterior applications: Check valves prevent backflow from pressure changes or environmental events like floods or freezing in underground or outdoor plumbing lines.

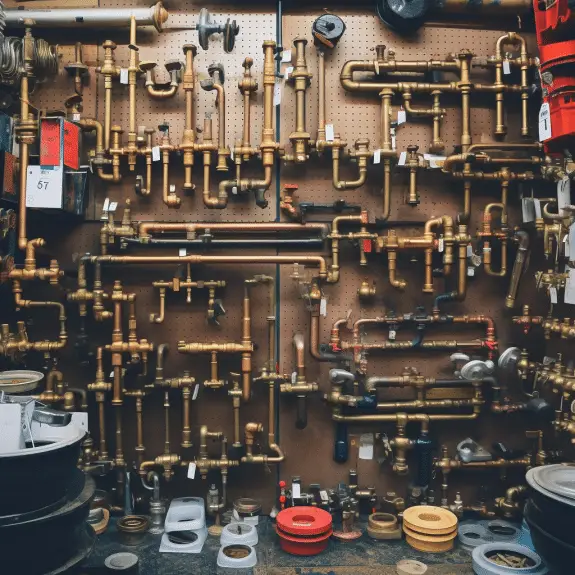

What Is Check Valve Types And Uses?

Check valves allow one-way flow as long as flow pressure stays steady and prevent reverse flow in the pipe system. We sell ball, piston, and stop check valves.

Residential plumbing, sewage, and wastewater use swing check valves.

A spring opens and closes a spring-loaded check valve. The spring accelerates fluid flow reactions and reduces water hammer when flow ceases. These valves serve pumps, irrigation, and high-pressure systems.

Ball check valves have conical seats and spherical discs. When fluid pressure surpasses opposite pressure, the ball leaves the seat, allowing flow. When flow reverses, the ball sits, preventing backflow. Water, wastewater, and industrial systems use ball check valves.

Dual-plate wafer check valves have two hinged semicircular plates. Plates allow fluid flow. Plates close to stop backflow. HVAC, fire protection, and oil and gas pipelines use dual-plate check valves.

What Is The Advantage Of Check Valve?

The Importance of Check Valves

The system fluid pressure opens them, then they close to prevent the fluid from flowing back toward the inlet.

Not letting backflow happen: One great thing about check valves is that they stop backflow. Check valves guard the pipes and potable water by only letting fluid run in one direction and blocking it from going backwards. It is very important to stop chemicals, dirty water, and other things that could damage lines from flowing backwards.

Safeguards Pumps and Appliances: Check valves protect plumbing-connected pumps and appliances. There is less pressure in the system because of the check valves. This keeps the system safe from damage caused by water hammer and pressure spikes. This safety measure keeps the machine working well and makes the pump last longer.

Lowers Water Hammer: Water hammer happens when the flow of water is suddenly stopped or switched, causing a pressure surge in the pipes.

Makes Plumbing Work Better: Check valves make plumbing work better by limiting the flow of fluids to one direction. They make sure that fluids like water move so that they can get where they need to go easily. This is very important in systems that have pumps or tools that need steady flow rates and pressure.

What Is The Maximum Pressure For A Check Valve?

Back pressure is limited to 1000 psi (69 bar) for 1/4″ and 200 for 3/8 to 1″.

Check valves’ maximum pressure depends on their kind, size, materials, and manufacturer’s specifications. Guidelines for common check valve maximum pressure:

Swing Check Valve: Swing check valves can withstand 125 to 250 psi. Industrial swing check valves may have higher pressure ratings of 1,500 psi or more.

Spring-Loaded Check Valve: Sometimes intended for higher pressures. Depending on valve size, materials, and construction, their maximum pressure ratings can be 150 to 600 psi or more.

Ball check valves can tolerate high pressures. The ball valve’s size, materials, and design determine its maximum pressure rating, which is usually 150 to 600 psi or greater.

Dual-Plate Check Valve: These valves can withstand 150 to 600 psi or more. Size, materials, and design determine the valve’s pressure-handling capacity.

Please note that these maximum pressure values are recommendations and manufacturer specifications may vary. To determine a check valve’s maximum pressure rating, see the manufacturer’s literature or product specifications.

What Is A Plumbing Check Valve?

A check valve, also called a one-way valve, is a device that allows the flow of fluids to move only in one direction. The primary purpose of a check valve is to prevent backflow in the system. Check valves are cheap, effective, and easy solutions to a potential issue.

Plumbing check valves control fluid flow and prevent backflow. The device allows fluid to flow in one direction while automatically blocking the other. A plumbing check valve is essential to system integrity and performance.

Pressure changes, water supply disruptions, and non-potable water or substance-introducing appliances or fixtures can induce backflow. Water contamination and piping damage can result from backflow.

Residential, commercial, industrial, and municipal plumbing check valves are used. Backflow-prone places include the main water supply line, appliances, fixtures, pumps, and branch lines. Plumbing check valves include swing, spring-loaded, ball, and dual-plate.

What Are The Benefits Of Using A Check Valve In Plumbing?

Backflow occurs when a fluid switches direction and contaminates drinking water with contaminants or unsafe water. If fluid flows one way, examine valves. Changes in direction close the valve, stopping flow. This keeps lines working and water clean.

Check valves are crucial for stopping contaminated water from entering the drinking water system. Limiting overflow prevents contaminants, other chemicals, and unsafe water from entering the clean water supply.

Backflow can put too much stress on pipes, pumps, and machines, breaking them. Check valves stop overflow, which lowers water pounding, pressure spikes, and pipe stress. The lines, pumps, and other parts will last longer, which will save money on repair and replacement costs.

Check valves make sure that fluids only flow in one way, which makes plumbing systems work better.

Can A Check Valve Be Installed In Any Direction In A Plumbing System?

On the body of most check valves, there is an arrow or some other sign that shows the direction of flow. This mark tells you how to place the valve and shows the best way for water to flow through it. To get the best performance, it is very important to follow this advice and place the check valve in the right way.

Putting in a check valve the wrong way can cause a number of issues. If you put the valve in backwards, it might not open or close properly, which could cause a leak or a slower flow rate. It’s possible for the valve to get stuck or damaged during backward installation, making it useless for stopping backflow.

Mistakes in construction can also cause problems like water hammer, higher pressure drops, or plumbing systems that work less efficiently. These issues may cause the lines to be under more stress, water flow to slow down, or even damage to the check valve itself.

Conclusion

A check valve is a critical component in plumbing systems that plays a vital role in maintaining the integrity and functionality of the system. Its purpose is to allow fluid flow in one direction while preventing backflow, which could lead to contamination of the potable water supply or damage to the plumbing infrastructure. By automatically opening and closing based on pressure differentials, check valves ensure the unidirectional flow of fluids and protect against the reversal of flow.

The installation of check valves at strategic points within a plumbing system provides several benefits. They prevent backflow, safeguarding the potable water supply from contamination and maintaining its cleanliness and safety. Check valves also protect pumps and appliances by relieving pressure and reducing the risk of damage caused by sudden changes in flow or water hammer effects. Additionally, they contribute to the overall efficiency of the system by ensuring consistent flow rates and preventing interruptions in fluid movement.

There are many varieties of check valves for plumbing applications.Swing, spring-loaded, ball, and dual-plate check valves are widely utilized for their various benefits. Choosing the appropriate check valve type depends on factors such as the fluid type, pressure, temperature, flow rates, and system specifications.