How To Tighten Plumbing Fittings

Introduction

How To Tighten Plumbing Fittings: Properly tightened plumbing fittings are crucial for maintaining a leak-free and efficient plumbing system. Whether you’re a seasoned DIY enthusiast or a homeowner looking to address minor plumbing issues, understanding how to tighten plumbing fittings correctly is an essential skill. This comprehensive guide will provide you with the knowledge and step-by-step instructions to ensure secure and reliable connections throughout your plumbing system.

The importance of properly tightened plumbing fittings cannot be overstated. Leaks from loose or poorly sealed fittings can cause severe water damage to your home and belongings. Leaky fittings waste water, raising utility bills and harming the environment. Learn how to tighten plumbing fittings to protect your property, save water, and optimize your plumbing system.

Threaded, compression, and other domestic plumbing fittings will be covered in this tutorial. It will also suggest items like adjustable wrenches, pipe wrenches, and Teflon tape. We’ll also compare Teflon tape and pipe thread sealant to help you choose the ideal one for your application.

How Do You Loosen And Tighten Pipe Fittings?

Turning the nut or tap clockwise will tighten it whilst turning it counter clockwise will loosen it.

Loosening and tightening pipe fittings is a fundamental skill for anyone dealing with plumbing repairs or installations. Whether you need to disassemble a section of plumbing to fix a leak or put together a new system, knowing the correct techniques is essential. This step-by-step guide will walk you through the process of both loosening and tightening pipe fittings to help you handle a wide range of plumbing projects with confidence.

Loosening Pipe Fittings:

Prepare the area: Before starting, turn off the water supply to the section you’ll be working on. This is vital to prevent any accidental leaks or water damage.

Determine the fitting type: Identify whether the fitting is threaded or compression. Threaded fittings have grooves on the inside that screw onto pipes, while compression fittings have a nut that compresses onto a pipe or valve.

Use the right tools: For threaded fittings, use two wrenches – one to hold the fitting steady and the other to turn the fitting counterclockwise. For compression fittings, loosen the nut by turning it counterclockwise using an adjustable wrench.

Apply lubricant (if needed): If the fitting is stuck, applying a penetrating lubricant like WD-40 can help ease its removal. Give it some time to work its way into the threads before attempting to loosen the fitting.

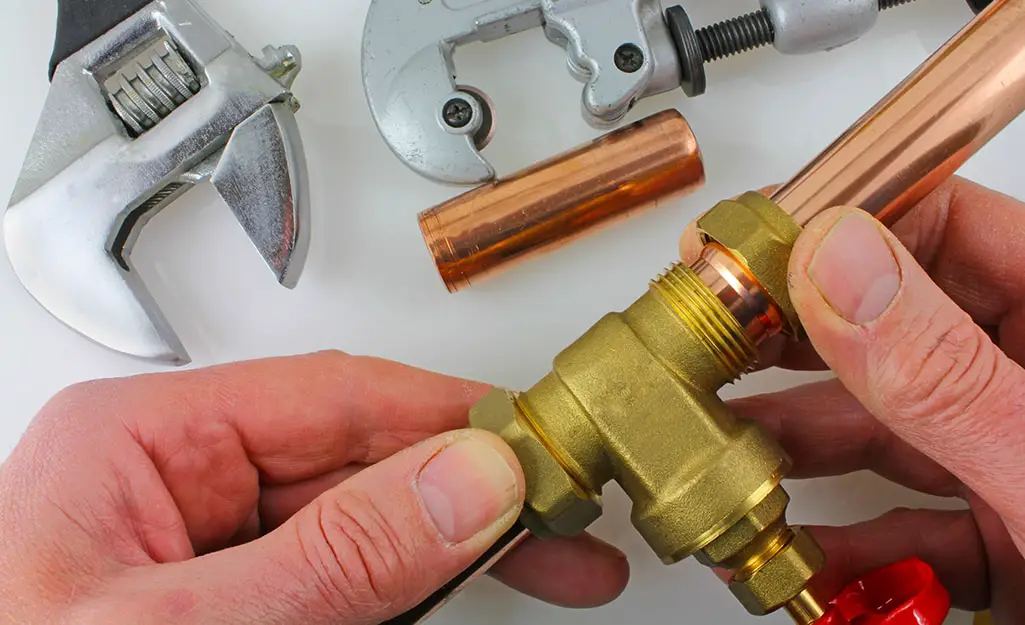

Tightening Pipe Fittings:

Ensure a clean connection: Make sure the pipe and fitting threads are clean and free of debris or old sealant. If using Teflon tape or pipe thread sealant, apply it in the direction of the threads to ensure a proper seal.

Hand-tighten first: Begin by hand-tightening the fitting onto the pipe. This ensures the threads align correctly.

Use wrenches (if necessary): Once hand-tightened, use two wrenches – one to hold the fitting and the other to turn it clockwise. For compression fittings, tighten the nut with an adjustable wrench until it is snug.

Avoid over-tightening: Take care not to apply excessive force, as this may damage the fitting or cause leaks. Stop tightening when you feel resistance, indicating a secure connection.

Remember, practice and attention to detail are essential when loosening and tightening pipe fittings. Following these steps will equip you to handle various plumbing projects efficiently and maintain leak-free connections throughout your plumbing system. Always exercise caution, and if you encounter any difficulties, don’t hesitate to seek professional assistance.

Can you overtighten fittings?

This is the fitting at the bottom of the inlet where the column nut attaches. Over tightening this nut can damage the threads on both the nut and the inlet fitting. It is possible to overtighten fittings, and doing so can have detrimental consequences. Overtightening refers to applying excessive force when tightening a pipe or plumbing fitting beyond its recommended torque or pressure limits. While it may seem like a way to ensure a secure connection, overtightening can lead to a range of problems that compromise the integrity of the plumbing system.

One of the primary risks of overtightening is damaging the fitting itself. Overly forceful tightening can distort or crack the threads, making it challenging to properly connect or disconnect the fitting in the future. This can lead to leaks or, in extreme cases, require the replacement of the fitting altogether, adding unnecessary costs and labor to a simple plumbing task.

Moreover, overtightening can cause the fitting to deform or crush the pipe it’s connected to. This can lead to restricted water flow, reduced water pressure, or even complete blockages in the plumbing system. Additionally, overtightening can weaken the surrounding pipe material, making it more susceptible to leaks or breaks under pressure over time.

To avoid overtightening fittings, it is crucial to use the right tools and apply only the recommended amount of force specified by the manufacturer. For threaded fittings, using two wrenches – one to hold the fitting steady and the other to tighten – can provide better control over the torque applied. For compression fittings, tightening the nut until snug is typically sufficient to ensure a secure seal.

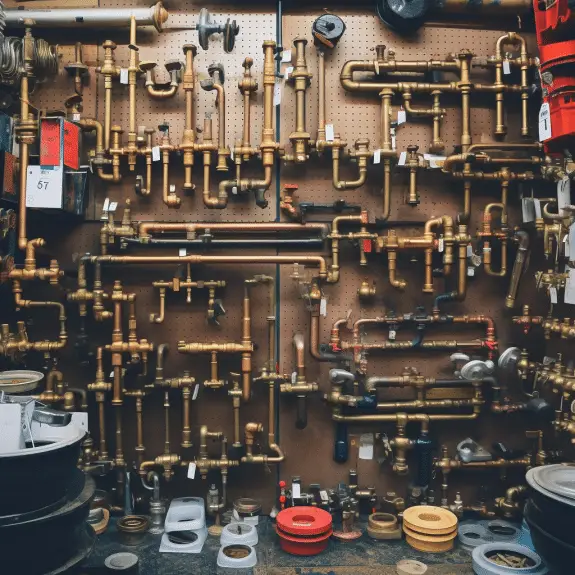

What Tool Should Be Used To Tighten Pipe Fittings?

Pipe Wrench

The pipe wrench serves as a plumber’s largest wrench. Plumbers use these heavy tools to tighten and loosen nuts and fittings on pipework. They typically use two of these wrenches together—one to hold a pipe in place and the other to rotate the nut or fitting in the appropriate direction.

When it comes to tightening pipe fittings, the appropriate tool depends on the type of fitting and its size. Using the right tool ensures a secure and leak-free connection without damaging the fitting or surrounding pipes. Here are the common tools used to tighten pipe fittings:

Adjustable Wrench: This versatile tool is the most commonly used for tightening pipe fittings. Its adjustable jaw allows it to fit various sizes of nuts and bolts, making it suitable for most threaded fittings. However, when using an adjustable wrench, be careful to avoid overtightening, as it can cause damage.

Pipe Wrench: Specifically designed for gripping and turning pipes and pipe fittings, a pipe wrench provides a strong grip that can handle high torque. Pipe wrenches come in various sizes, so ensure you select the appropriate one for the fitting you are working on. It is essential to use a pipe wrench on larger pipe fittings, as an adjustable wrench may not provide enough leverage.

When working on your plumbing system, ensure you have the correct tools on hand for the specific fitting type and size. Using the wrong tool can lead to overtightening, under-tightening, or damaging the fitting, resulting in leaks and potential hazards. If you are unsure about the right tool or technique to use, it is always best to seek guidance from a professional plumber to ensure the job is done correctly and efficiently.

What Is The Proper Tightening Of Pipe Threads?

As a general guideline, after hand-tight engagement, tighten 2-3 full turns for sizes up to 1 inches for NPT fittings. You should have between 3.5 and 6 engaged threads. Any number outside of this range may indicate either under or over tightening of the joint or out of tolerance threads.

Properly tightening pipe threads is crucial to creating a reliable and leak-free connection. Whether you are dealing with threaded pipe fittings or connecting pipes together, following the correct tightening procedure is essential. Here are the steps to achieve the proper tightening of pipe threads:

Clean the Threads: Before assembling the connection, ensure the pipe threads are clean and free from debris, old sealant, or corrosion. Use a wire brush or a cloth to clean the threads thoroughly.

Apply Thread Sealant or Teflon Tape: For most threaded connections, it is advisable to apply a thread sealant or Teflon tape. These materials help create a secure and watertight seal between the threads, preventing leaks. When using Teflon tape, wrap it clockwise around the male threads to avoid it unraveling during tightening.

Hand-Tighten First: Begin by hand-tightening the fittings together. Turn the fitting clockwise with your hands until it is snug. Hand-tightening ensures that the threads align correctly and prevents cross-threading.

Use Two Wrenches: After hand-tightening, use two wrenches – one to hold the fitting steady and the other to turn the fitting clockwise. The wrench holding the fitting should be positioned on the flat surfaces of the fitting, not on the threaded area, to avoid damaging it.

Apply Steady Pressure: Slowly apply steady pressure to the wrench turning the fitting, gradually increasing the force. Avoid using sudden or excessive force, as it can lead to overtightening. Keep turning until the fitting is snug and forms a watertight seal.

Is Teflon tape necessary for plumbing?

Hydrophobic polytetrafluoroethylene (PTFE) exhibits little friction and is beneficial. Plumbers and irrigation contractors need PTFE tape for pipes.

Plumbing uses teflon tape extensively. Teflon tape, often known as plumber’s tape or PTFE tape (polytetrafluoroethylene), seals threaded pipe fittings and prevents plumbing leaks. Plumbing requires Teflon tape for these reasons:

Creates a Watertight Seal: Teflon tape seals threaded pipe fittings well. Water does not leak through fitting male threads when the tape is correctly applied.

Prevents Leaks: Plumbing systems are under constant pressure, and even little leaks can waste water and damage buildings. Teflon tape prevents threaded joint leaks, saving water damage and repairs.

Easy to Apply: Teflon tape applies easily. Cover the whole threaded part of the male fitting by wrapping the tape in the direction of the threads. It sticks well and stays put during connection assembly.

Heat and Chemical resilience: Teflon tape can be used in hot and cold water plumbing systems due to its resilience to high temperatures and many chemicals.

Can You Over Tighten Plumbing?

The unique construction and configuration of pipes means they are made to be tightened just enough, making them super tight can actually prevent water from flowing properly. Over-tightening will also warp the rubber plumbing fittings inside the pipes over time and increase the risk of leaks.

Over tightening refers to applying excessive force when tightening a plumbing connection beyond the recommended torque or pressure limits. Here are the reasons why over tightening plumbing is a concern:

Damaging the Fittings: Applying too much force can distort or crack the fittings, especially those made of plastic or more delicate materials. This damage weakens the fitting’s structure, making it more susceptible to leaks, cracks, or complete failure over time.

Stripped Threads: Over tightening can strip the threads on both the fitting and the pipe, making it difficult or impossible to properly secure the connection in the future. Stripped threads can result in a loose fitting and water leaks.

Leaks and Water Damage: Over tightening can displace the sealant material, such as Teflon tape or pipe thread sealant, from its intended position, compromising the seal. This can lead to leaks around the fitting, causing water damage to the surrounding area.

To avoid over tightening plumbing fittings, it is essential to use the right tools, such as wrenches, and apply only the recommended amount of force specified by the manufacturer. Following the appropriate guidelines and being cautious during the tightening process can prevent these potential issues and ensure secure and leak-free plumbing connections. If you are unsure about the proper tightening procedure or encounter resistance during the process, it is best to seek advice from a professional plumber to ensure the job is done correctly and safely.

What Is The Best Tool For Tightening Plumbing?

Pipe Wrench

The pipe wrench serves as a plumber’s largest wrench. Plumbers use these heavy tools to tighten and loosen nuts and fittings on pipework. They typically use two of these wrenches together—one to hold a pipe in place and the other to rotate the nut or fitting in the appropriate direction.

The best tool for tightening plumbing fittings largely depends on the specific type and size of the fitting you are working with. Different fittings may require different tools for optimal results. Here are some of the best tools commonly used for tightening plumbing:

Adjustable Wrench

This versatile tool is a staple for plumbing tasks. Its adjustable jaw allows it to fit various sizes of nuts and bolts, making it suitable for most threaded fittings. An adjustable wrench is an excellent all-purpose tool for tightening and loosening plumbing connections.

Pipe Wrench

Specifically designed for gripping and turning pipes and pipe fittings, a pipe wrench provides a strong grip that can handle high torque. There are different types and sizes of pipe wrenches, making them ideal for larger plumbing fittings and pipe connections.

Basin Wrench

A basin wrench is essential for reaching fittings in tight spaces, such as those under sinks. Its long handle and pivoting jaw make it ideal for tightening nuts on faucet supply lines and other hard-to-reach fittings.

Tube Wrench (Flare Nut Wrench)

When dealing with compression fittings, a tube wrench, also known as a flare nut wrench, is the best tool for the job. It provides a precise grip on the nut without damaging it, ensuring a secure connection.

Socket Wrench

Socket wrenches are handy for tightening hexagonal or square-shaped nuts and bolts. They are particularly useful for some plumbing applications that require a more precise and snug fit.

Combination Wrench

A combination wrench is a double-ended tool with one open end and one closed end. It is useful for accessing tight spaces and can work well for some plumbing fittings.

Torque Wrench

For critical applications where specific torque values are necessary, a torque wrench is the best choice. It ensures that fittings are tightened to the manufacturer’s recommended specifications, preventing over-tightening or under-tightening.

It is essential to select the right tool for the job to avoid damaging the fittings and ensure leak-free connections. Always use the appropriate tool that matches the fitting size and type. If you are unsure about the correct tool or technique for your plumbing project, consulting with a professional plumber can provide valuable guidance and ensure the job is done safely and effectively.

What should I do if a fitting is still leaking after tightening?

If a fitting is still leaking after tightening, it can be frustrating and concerning. However, there are several steps you can take to address the issue and achieve a leak-free connection:

Turn off the Water

Before attempting any further adjustments, turn off the water supply to the affected area. This will prevent any further water leakage and minimize potential damage.

Inspect the Fitting

Check the fitting and surrounding area for any signs of damage, cracks, or defects. Ensure that the fitting is properly aligned and seated on the pipe. If you notice any issues, such as damaged threads or a cracked fitting, it may need to be replaced.

Reapply Teflon Tape or Sealant

If the fitting appears to be in good condition, you may need to reapply Teflon tape or pipe thread sealant to the threads. Make sure to apply it in the correct direction, as specified by the manufacturer, and wrap it around the male threads thoroughly.

Proper Tightening Technique

When tightening the fitting again, be mindful of the proper technique. Use the appropriate tool, such as an adjustable wrench or pipe wrench, and apply steady, even pressure. Avoid over-tightening, as this can lead to further problems.

Check for Cross-Threads

It’s possible that cross-threads may have occurred during the initial tightening, especially if the fitting was forced onto the pipe at an angle. Inspect the threads for any signs of misalignment or damage, and if cross-threading is suspected, carefully re-thread the fitting to ensure a proper connection.

Consider Using Pipe Dope

In some cases, using a pipe thread sealant (pipe dope) in addition to Teflon tape can provide an extra layer of protection against leaks. Just ensure that the pipe dope is compatible with the fitting material and the plumbing system.

Use New Fittings or Gaskets

If the fitting still leaks despite your best efforts, it may be necessary to replace the fitting or gaskets. It’s crucial to use high-quality fittings and gaskets that match the specific plumbing system requirements.

Seek Professional Help

If the issue persists or if you are unsure about the cause of the leak, it’s best to seek assistance from a professional plumber. They have the expertise and tools to diagnose and resolve complex plumbing problems effectively.

Remember, addressing leaks promptly is essential to prevent water damage and wastage. With proper inspection, correct technique, and, if needed, professional assistance, you can resolve the issue and achieve a reliable, leak-free plumbing connection.

Conclusion

Understanding the importance of correctly tightened fittings, we explored the potential consequences of overtightening and the risks associated with under-tightening. Overtightening can lead to damaged fittings, stripped threads, and potential water leaks, while under-tightening may result in loose connections and water wastage. Striking the right balance and using the appropriate tools and techniques are essential for achieving secure and reliable plumbing connections.

Teflon tape emerged as a necessary component for threaded connections, offering an easy-to-use and effective method for creating watertight seals. Its versatility, compatibility with various plumbing materials, and cost-effectiveness make it a valuable asset for a range of plumbing applications.

Throughout the guide, safety precautions were emphasized to protect both the plumbing system and the individual carrying out the work. Turning off the water supply before starting any work and avoiding the use of excessive force are critical measures to prevent potential injuries and damages.

By adhering to the proper tightening techniques for different types of fittings and utilizing the correct tools, plumbing enthusiasts can achieve successful and efficient results. Hand-tightening fittings before using wrenches and checking for leaks after tightening are essential steps to ensure the connection is secure and leak-free.