How To Measure Plumbing Fittings

Introduction

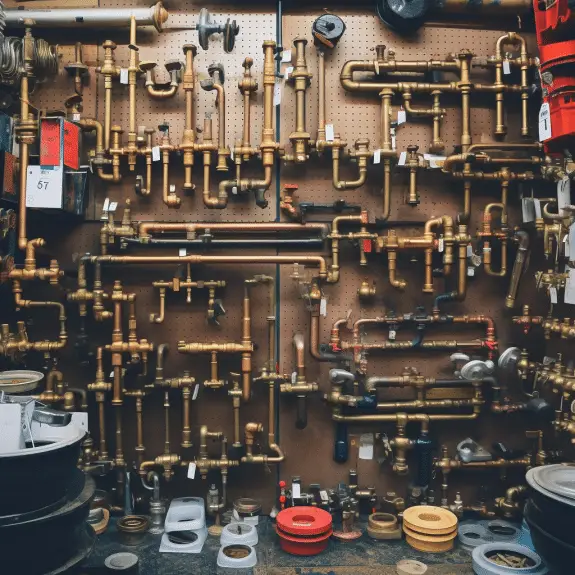

How To Measure Plumbing Fittings: Accurate measurement of plumbing fittings is crucial for successful installation and efficient plumbing systems. Whether you’re a professional plumber or a DIY enthusiast, understanding how to measure plumbing fittings is essential for ensuring a leak-free and properly functioning system.

First, you should know that pipe fittings come in different sizes, shapes, and materials. Every fitting in a plumbing system has a specific job to do, from pipes and links to valves and adapters. To make sure compatibility and stop leaks, exact measurement is necessary.

One of the fundamental measurements in plumbing fittings is the diameter. Understanding the diameter of pipes and fittings is crucial for determining their compatibility and how they will fit together. Calipers or tape measures can measure the inner and outer diameters.

For parts like connectors, couplings, and valves, you also need to measure the length and depth. If you measure these measurements correctly, the parts will fit together securely and tightly, which will stop leaks and other problems that could happen over time.

It is very important to correctly measure the thread size and type when using threaded fittings. To do this, you need to know the thread size, diameter, and whether it’s straight or tapered. By using a thread gauge or a thread pitch measurement tool, you can make sure that threaded joints fit correctly and avoid leaks and loosening.

How are fitting sizes measured?

Wrap a string around the pipe (if it’s a male thread) and mark where the string touches. Determine the length between the end of the string and the touch point, which gives you its circumference. To get diameter, divide the circumference by pi (3.14159). You may need to convert decimal to fraction.

In plumbing, fitting sizes are usually measured using certain rules and methods. The way to measure depends on the type of fitting. Knowing these different ways to measure is important for choosing the right fittings and making sure they work with the rest of the water system.

Usually, fitting ID or OD is used to measure diameter. Pipe diameters are usually determined by their outside width. Copper pipes are measured by their outside diameter. Standard-sized PVC pipes are another example.

However, threaded fittings require thread size and type measurements. Measure the diameter and thread pitch (threads per inch) to determine thread size. Also, determine if the threads are tapered or straight. A thread gauge or thread pitch measurement tool can properly measure them.

How do I know my plumbing pipe size?

To find it, use a bendable measuring tape to go around the pipe’s outside. The answer is about 3.14159 times pi, which is the round number. Take 12.57 inches (319 mm) as an example. If you divide that number by pi, you get 4 inches (100 mm) as the outside circle.

Measure the diameter: The most common way to determine the size of a pipe is by measuring how wide it is. To find the pipe’s outside diameter (OD), use a tape measure or tools. If the end of the pipe has a threaded connection, measure the outside width of that part. A lot of the time, standard pipe sizes are marked with their specified size, which is the pipe’s inside diameter (ID).

Check for markings: Many pipes have marks or labels that tell you what size they are. Look for material that is printed or raised on the pipe’s surface. Some of these markings could be the nominal size, the type of material, or information about the maker. But some pipes, especially older ones or ones that were made just for you, won’t have marks that you can see.

Consult plumbing codes and standards: Plumbing codes and standards provide specifications for pipe sizes based on the intended use and the volume of water flow. Familiarize yourself with the local plumbing codes or refer to recognized industry standards to determine the appropriate pipe size for your application.

What size are plumbing fittings?

The most common CTS fittings are 1/2 inch, 3/4 inch, and larger sizes because they’re used for household plumbing more frequently than ID nominal size parts. Smaller appliances, like under counter filters that run to your refrigerator or ice maker, use OD sized parts.

You must know the plumbing fittings’ sizes to choose the right parts and ensure they fit properly.

Diameter is usually used to measure plumbing connections. The width of the pipe or fitting is usually stated in inches or millimeters.

Along with its diameter, the length of a pipe fitting is also a key number. How far apart the ends of a fitting or clip are tells you how long it is. One thing that needs to be thought about is the length of a coupling or connector to make sure it fits properly between water lines or parts.

To what standards are PVC couplings held?

PVC Pipe sizes are so named by measuring the inside diameter (also called the bore) of the PVC pipe and not the outside diameter. If you measure the outside diameter, it will give you a larger reading than the actual PVC Pipe Size.

Measurements of PVC fittings are usually nominal. Not specific measurements, but the fitting’s typical internal diameter (ID). Typically, the typical size ranges from ½ inch to 12 inches or more. It shows the interior diameter of the PVC pipe it fits.

It’s important to keep in mind, though, that the real sizes of PVC fittings may not always match their nominal sizes. This is because of tolerances in manufacturing and different norms in different areas or between manufacturers. As a result, it is always a good idea to check the fittings’ real sizes before connecting them.

It’s important to think about the hole depth when measuring PVC fittings. The socket depth tells you how long the hole in the fitting is where the pipe goes in. Ensure the pipe goes all the way into the hole for a proper fit. Putting the pipe in too shallow could weaken the joints or cause leaks.

What is the size of a PVC pipe?

The most common PVC pipe sizes are 1½ inches (used as drain pipes for kitchen sinks, bathroom vanity, and tubs). 2 inches (used as drain pipes for washing machines and shower stalls), 3 inches (used in piping toilets). 4 inches (used to connect homes to sewer system). The size of a PVC pipe refers to its nominal size. Plumbers utilize standardized designations. The most common PVC pipe sizes are fractions or whole numbers.

For example, common PVC pipe sizes include ½ inch, ¾ inch, 1 inch, 1 ¼ inch, 1 ½ inch, 2 inches, 3 inches, 4 inches and so on. These sizes represent the approximate inside diameter (ID) of the pipe.

It’s important to note that the actual outside diameter (OD) of a PVC pipe. Can vary depending on factors such as the schedule or thickness of the pipe. PVC pipes are manufactured in different schedules, which determine the wall thickness and pressure rating of the pipe.

The most common schedules for PVC pipes are Schedule 40 and Schedule 80. Schedule 40 PVC pipes have a slightly larger OD compared to Schedule 80 pipes of the same nominal size. This is because Schedule 80 pipes have thicker walls to handle higher pressure applications.

For example, a 1-inch Schedule 40 PVC pipe typically has an outside diameter (OD) of about 1.315 inches. While a 1-inch Schedule 80 PVC pipe has a slightly smaller OD of approximately 1.315 inches.

It’s important to refer to the manufacturer’s specifications or consult a PVC pipe sizing chart to determine the exact dimensions. Including the OD, ID, and wall thickness, for the specific type and schedule of PVC pipe you are using.

How do I measure the depth of a plumbing fitting?

To measure depth, use a ruler or caliper to determine. The distance from the top edge to the bottom edge of the fitting. This measurement is crucial for ensuring a secure and proper fit.

As a plumber, you need to know how deep a pipe goes to make. Sure it fits safely and properly in your system. The depth number tells you how far the fitting goes from its very top to very bottom. It is very important to get this measurement right for parts like connectors, valves, couplings and others that need. To be placed at a certain depth.

Gather the necessary tools: You will need a ruler or a caliper to accurately measure the depth of the fitting. Ensure that the ruler or caliper is long enough to reach from the top edge to the bottom edge of the fitting.

Position the fitting: Place the fitting on a flat surface or hold it firmly in your hand. Ensuring that it is in the correct orientation for measurement.

Align the measuring tool: Position the ruler or caliper against the top edge of the fitting. Ensuring that it is parallel to the fitting’s length.

Take the measurement: Carefully slide the ruler or caliper down along the side of the fitting until it reaches the bottom edge. Read and note the measurement displayed on the ruler or caliper.

Confirm the measurement: Double-check the measurement to ensure accuracy. If necessary, take multiple measurements to ensure consistency.

Can I measure plumbing fittings without specialized tools?

You can get accurate readings with special tools. But you can also get close with common tools like rulers and tape measures. For precision, though, it’s best to spend money on specialized tools.

You can use a ruler or tape measure to find out. Whether the diameter of a pipe fitting is the inner or outer diameter. These tools aren’t as exact as calipers, but they can give you a good idea of the fitting’s size and whether it works with other parts.

A ruler or tape measure can be used to find out how long a link. Coupling or valve is all the way around. Make sure the fitting is fully stretched out or squeezed before measuring it from one end to the other. Specialized depth tools are better at measuring depth. But you can still use a ruler or caliper to guess the depth of a fitting by measuring. From the top edge to the bottom edge.

Are there any standard measurement charts available for plumbing fittings?

Yes, you can find measurement charts and tables that show the normal sizes for different plumbing fittings. You can use these charts as guides to find the right sizes for fittings.

Measurement charts are especially useful when working with different materials like PVC, copper, or brass. As each material may have specific sizing requirements. These charts help ensure that the correct fitting sizes are chosen for the specific material being used.

Additionally, measurement charts may include information on pressure ratings, flow rates, and other relevant technical details. This allows plumbers, contractors, and DIY enthusiasts to make informed decisions about the suitability of a fitting for a particular plumbing system or application.

For these charts, you can search the Internet, read plumbing books, or look through company brochures. Most of the time, companies post their measurement charts online so that people can print or share them.

Conclusion

Measuring plumbing parts correctly is a very important skill that all plumbers and people. Who like to do their own projects should have. If you know how to measure plumbing parts correctly, you can make. Sure they work with each other, stop leaks and build a plumbing system that works well.

If you measure the diameter of pipes and fittings properly. You can see if they will fit together and how they will connect. To make sure that valves, couplings, and fittings fit tightly and firmly, you need to know their length and depth. This will stop leaks and other problems that could happen over time. It’s also important to know the thread type and size to make sure the link fits right and doesn’t leak or come loose.

Mastering the art of measuring plumbing fittings is an essential skill for any plumbing endeavor. By understanding the dimensions, materials, and tools involved. You can ensure a proper fit, prevent leaks, and create a reliable plumbing system that will stand the test of time.