Revolutionizing Construction: The Power of 3D Printing

The construction industry is on the brink of a technological revolution with 3D printing technology. Also known as additive manufacturing, it has the potential to redefine traditional building methods and reshape the future of the construction industry. With 3D printing, architects and engineers can have unprecedented design freedom and create complex architectural forms that were previously challenging. This technology offers advantages such as reduced material waste, faster construction time, and the ability to customize and optimize building components.

Key Takeaways

- 3D printing technology has the potential to revolutionize the construction industry.

- Architects and engineers can enjoy greater design freedom with 3D printing.

- 3D printing allows for the customization and optimization of building components.

- The future of construction is embracing innovative building methods, including 3D printing technology.

How 3D Printing Works in Construction

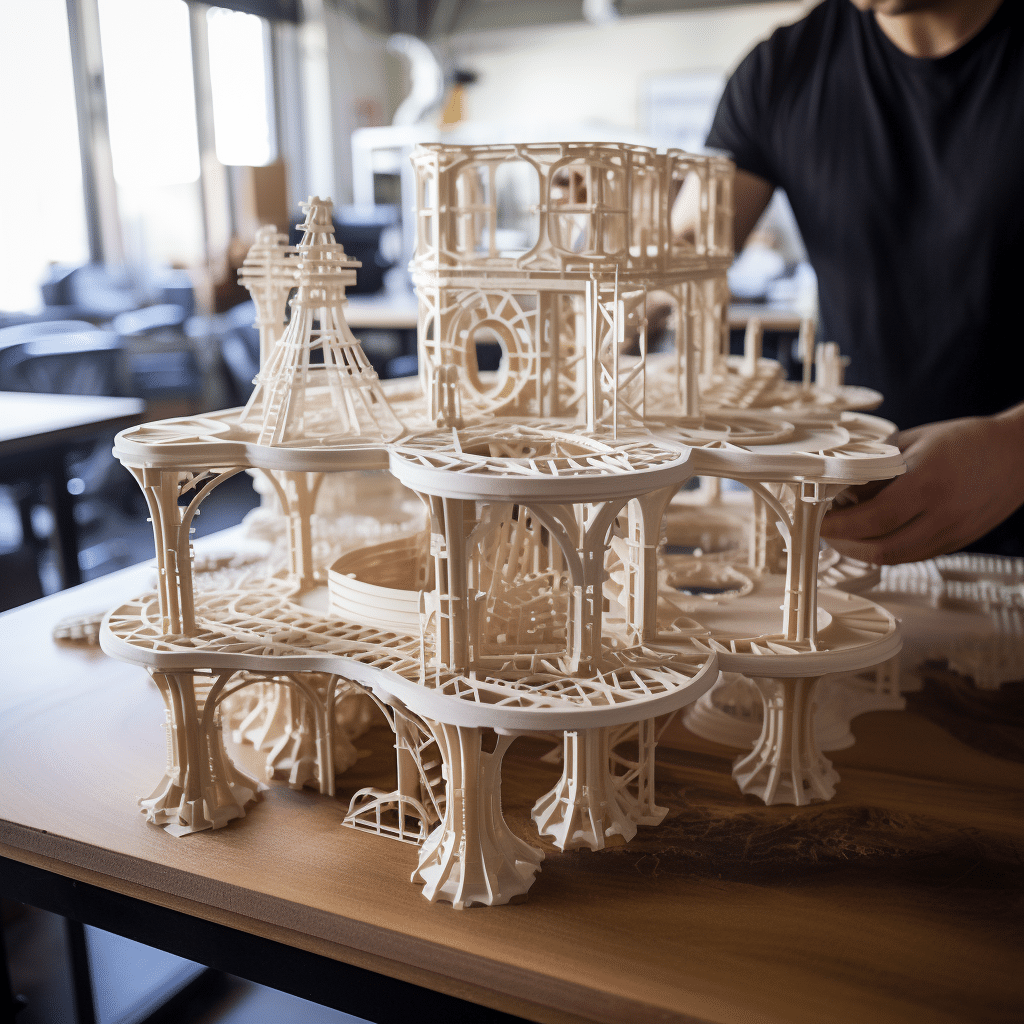

3D printing in construction is a fascinating and innovative process that involves the use of computer-aided design (CAD) software to create a digital blueprint of the building. This digital model serves as the foundation for the 3D printer to bring the design to life. The printer works by depositing layers of material, such as concrete or a composite, based on the instructions from the digital blueprint.

The layer-by-layer construction method used in 3D printing allows for precise control over material distribution, resulting in efficient and robust structures. This process not only saves time but also enables architects and engineers to create complex architectural forms that were previously challenging to achieve.

With 3D printing, customization and optimization of building components become possible. This technology offers architects and engineers unprecedented design freedom, allowing them to explore creative and unique designs. Additionally, 3D printing in construction has the potential to significantly reduce material waste compared to traditional construction methods. By only using the necessary amount of material for each layer, 3D printing promotes sustainability in the construction industry.

The Advantages of 3D Printing in Construction:

- Unprecedented design freedom

- Reduced material waste

- Faster construction time

- Promotes sustainability

“3D printing in construction allows for precise control over material distribution, resulting in efficient and robust structures.”

To better understand the process, let’s take a closer look at the key steps involved in 3D printing a building:

- Design Phase: Create a digital model of the building using CAD software.

- Material Selection: Choose the appropriate material for 3D printing, such as concrete.

- Printing Process: The 3D printer deposits the material layer by layer, following the digital blueprint.

- Post-Processing: Finishing touches may be required, such as removing support structures or fine-tuning the final product.

By understanding how 3D printing works and its advantages in construction, we can begin to appreciate the potential of this technology in shaping the future of the industry.

Table: Advantages of 3D Printing in Construction

| Advantages | Explanation |

|---|---|

| Unprecedented design freedom | Ability to create complex architectural forms |

| Reduced material waste | Only uses the necessary amount of material for each layer |

| Faster construction time | Layer-by-layer construction method |

| Promotes sustainability | Minimizes material waste and carbon footprint |

Benefits of 3D Printing in Construction

There are various benefits of employing 3D printing in building. One of the primary advantages is the design freedom it affords. Architects and engineers may now construct intricate and imaginative designs that were previously difficult to attain. With 3D printing, complicated architectural forms and customized building components may be easily realized, stretching the boundaries of traditional construction methods.

Another notable benefit is the reduction in material waste. 3D printing technology enables for exact control over material distribution, ensuring that only the necessary amount of material is utilized for each layer. This not only minimizes waste but also contributes to a more sustainable construction process. Additionally, the layer-by-layer construction approach of 3D printing provides shorter manufacturing periods compared to traditional methods, saving both time and expense.

In summary, the benefits of 3D printing in construction include design freedom, material waste reduction, faster construction time, and sustainability. This technology has the potential to revolutionize the construction industry by offering unprecedented possibilities in terms of design, efficiency, and environmental impact. As the market for 3D printed buildings continues to grow, we can expect to see further advancements and adoption of this innovative technology in the future.

Key Steps in 3D Printing a Building

In order to successfully 3D print a building, several key steps need to be followed. These steps include the design phase, material selection, printing process, and post-processing.

Design Phase

Designing the building involves creating a digital model with CAD software. This model is the 3D printer’s blueprint. This phase lets architects and engineers test designs and meet specifications. The design phase is vital to 3D printing since errors or miscalculations might damage the final structure.

Material Selection

Once the design is finalized, the next step is material selection. Concrete is the most commonly used material for construction 3D printing due to its durability and strength. However, other materials such as composites or plastics can also be used. The material selected must be suitable for 3D printing and meet the structural requirements of the building.

Printing Process

After design and material selection, printing begins. Following design specifications, the 3D printer deposits the material layer by layer. Layers harden and dry before adding more, building the structure. The printing process must be monitored and controlled to place each layer accurately. Layer-by-layer construction allows precise material distribution, creating efficient and robust structures.

Post-Processing

This can include the removal of support structures, smoothing or polishing surfaces, and any necessary adjustments to ensure the structural integrity of the building. Post-processing is essential for achieving the desired aesthetic and functional qualities of the 3D printed structure.

| Step | Description |

|---|---|

| Design Phase | Create a digital model of the building using CAD software. |

| Material Selection | Select the appropriate material for the 3D printing process. |

| Printing Process | Deposit the material layer by layer to build the structure. |

| Post-Processing | Refine the final product through necessary adjustments and finishing techniques. |

The Potential of 3D Printed Building Materials

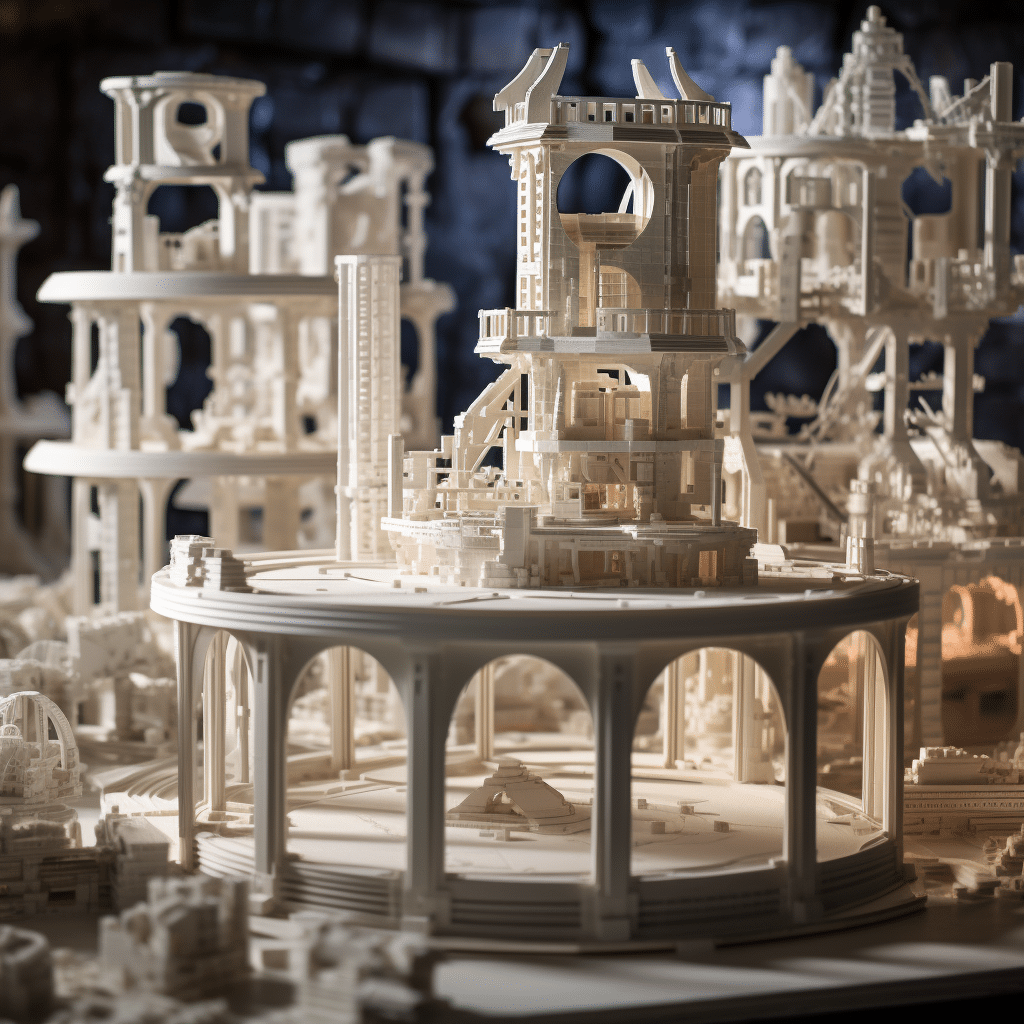

3D printed building materials have the potential to revolutionize the construction industry. The ability to customize and optimize building components allows architects and engineers to create structures that meet specific requirements and push the boundaries of traditional construction methods. One of the key advantages of 3D printing in construction is the ability to create complex geometries that were previously challenging to achieve. This innovative technology offers precise control over material distribution, resulting in highly efficient and robust structures.

With 3D printed building materials, architects and engineers have unprecedented design freedom. They can explore innovative designs and create unique architectural forms that were once thought to be impossible. The layer-by-layer construction process of 3D printing allows for precise control over material placement, ensuring structural integrity and efficient resource utilization. From intricate facades to organic shapes, the possibilities for architectural expression are limitless.

Furthermore, 3D printed building materials can lead to significant advancements in sustainability. By reducing material waste and optimizing material usage, 3D printing in construction promotes environmentally friendly practices. Additionally, the faster construction time achieved through additive manufacturing can minimize disruption to the surrounding environment. This technology also has the potential to make construction more cost-effective in the long run, as the customization and optimization of building components can lead to improved energy efficiency and reduced maintenance costs.

Table: Comparing Traditional Construction Methods with 3D Printing

| Traditional Construction Methods | 3D Printing |

|---|---|

| Limited design freedom | Unprecedented design freedom |

| Higher material waste | Reduced material waste |

| Longer construction time | Faster construction time |

| Standardized building components | Customizable and optimized building components |

| Difficult to achieve complex geometries | Easily achievable complex geometries |

3D printed building materials have great potential in construction. With the ability to customize, optimize, and create complex geometries, this technology is changing building design and construction. Using precise material distribution, architects and engineers can build efficient and sustainable structures. We can expect more innovative 3D printing applications in construction as this technology advances.

Showcasing 3D Printed Building Materials

This event provided a unique platform for industry professionals, researchers, and enthusiasts to explore and experience various innovative construction technologies, including 3D printing. Live demonstrations of cutting-edge technologies were a highlight of the event, allowing participants to witness firsthand the capabilities of 3D printed building materials in action.

The event featured live demonstrations of robotic construction, advanced formwork systems, and smart building technologies, among others. These demonstrations provided valuable insights into the practical applications of 3D printing technology in the construction industry. Industry experts shared their knowledge and expertise, discussing the benefits, challenges, and future prospects of 3D printed building materials.

Participants had the opportunity to interact with industry leaders, network with like-minded professionals, and engage in thought-provoking discussions. The event served as a catalyst for collaboration and knowledge exchange, fostering innovation in the construction industry. By showcasing the latest advancements in 3D printed building materials, the event highlighted the transformative potential of this technology and its role in shaping the future of construction.

| Key Highlights of the Event: |

|---|

| Live demonstrations of 3D printing technology |

| Discussions on the benefits and challenges of 3D printed building materials |

| Networking opportunities with industry professionals |

| Exploration of innovative construction technologies |

The Growing Market for 3D Printed Houses

As the construction industry adopts 3D printed building materials, the market for 3D printed houses is growing. Grande View Research estimates that the global market for 3D-printed houses was worth USD 13.84 billion in 2021 and will grow 20.8% from 2022 to 2030.

In addition to market growth, 3D printer shipments are expected to rise. This significant shipment increase shows rising global demand for 3D-printed houses.

The construction industry is recognizing the numerous advantages of 3D printed houses, such as increased efficiency, sustainability, affordability, and design flexibility. These houses offer reduced construction time, lowered costs, and improved planning reliability. Additionally, 3D printing technology minimizes material waste and reduces the carbon footprint, making it an environmentally friendly option. The optimization of material usage in 3D printing can also contribute to more affordable housing solutions. Furthermore, the design flexibility of 3D printed houses allows for the creation of unique and customized living spaces.

The growing market for 3D printed houses signifies a revolution in the construction industry. As technology advances, we can expect even more innovations and advancements in the field of 3D printing, further shaping the future of construction.

| Year | Market Size (USD Billion) | Number of 3D Printer Shipments (Million Units) |

|---|---|---|

| 2021 | 13.84 | 2.2 |

| 2022 | 16.71 | 3.8 |

| 2023 | 20.18 | 6.5 |

| 2024 | 23.72 | 9.4 |

| 2025 | 27.84 | 12.6 |

Examples of 3D Printed Houses

Several impressive examples of 3D printed houses have already been built, showcasing the potential and versatility of this innovative technology. These projects push the boundaries of traditional construction methods and demonstrate the capabilities of 3D printed building materials. Let’s take a closer look at some notable examples:

House Zero

Located in Austin, Texas, House Zero is a prime example of 3D printing’s ability to create modern and sustainable homes. This project incorporates advanced technologies and sustainable design principles, resulting in an energy-efficient and environmentally friendly dwelling.

Mighty Buildings

Situated in southern California, Mighty Buildings has successfully constructed a net-zero energy home using 3D printing technology. This project showcases the efficiency and sustainability of 3D printed building materials, offering a glimpse into the future of environmentally conscious housing.

Project Milestone

In the Netherlands, Project Milestone has demonstrated the feasibility of 3D printed concrete houses. This groundbreaking initiative has proven that 3D printing can be utilized to construct durable and structurally sound homes, revolutionizing the traditional building industry.

Tecla

Tecla, an innovative housing prototype in Italy, combines traditional clay materials with 3D printing technology. This unique approach combines sustainability with design flexibility, creating low-carbon housing solutions that blend seamlessly with the natural environment.

Kamp C

Europe’s largest 3D-printed house, located in Belgium, is a striking example of the possibilities offered by 3D printed building materials. Kamp C showcases the potential for large-scale construction using 3D printing technology, demonstrating its versatility and efficiency.

| Example | Location | Main Features |

|---|---|---|

| House Zero | Austin, Texas | Modern, sustainable home incorporating advanced technologies |

| Mighty Buildings | Southern California | Net-zero energy home built using 3D printing technology |

| Project Milestone | The Netherlands | Feasibility of 3D printed concrete houses |

| Tecla | Italy | Low-carbon housing prototype combining clay and 3D printing |

| Kamp C | Belgium | Europe’s largest 3D-printed house showcasing versatility and efficiency |

The Advantages of 3D Printed Houses

3D-printed houses have many advantages over traditional construction methods. Efficiency is a major benefit. Sustainability and efficiency are other benefits of 3D-printed houses. This technology optimises material use, reducing waste and carbon footprint. 3D printed houses reduce material waste, making construction greener.

The affordability of 3D-printed houses is another benefit. Cost savings result from precise material distribution and usage optimization. These houses are cheaper than traditional construction methods, saving homeowners and builders money.

Furthermore, 3D printed houses provide design flexibility. This technology allows architects and designers to create unique and customized living spaces, pushing the boundaries of traditional building methods. Whether it’s complex geometries or innovative designs, 3D printing offers unparalleled design freedom and opens up new possibilities in architectural creativity.

| Advantages of 3D Printed Houses |

|---|

| Efficiency |

| Sustainability |

| Affordability |

| Design Flexibility |

Conclusion

With their innovative technology, they offer exciting possibilities for architects and engineers to push the boundaries of design and create complex and customized structures. The advantages of 3D printing, such as reduced material waste and faster construction time, make it a sustainable and cost-effective option for the industry.

As the market for 3D printed houses continues to grow, we can expect to see further advancements in this field. The ability to optimize material usage and achieve precise control over material distribution allows for efficient and robust structures. This technology not only offers efficient construction methods but also opens up opportunities for sustainable and affordable housing.

With ongoing developments in 3D printing technology, the construction industry is on the cusp of a revolution. As we move forward, it is clear that 3D printing will play a crucial role in shaping the future of construction.

FAQ

What is 3D printing in construction?

3D printing in construction is a process that uses computer-aided design (CAD) software and a 3D printer to create buildings. The printer deposits layers of material based on a digital blueprint, gradually building the structure layer by layer.

What are the benefits of using 3D printing in construction?

3D printing in construction offers design freedom, reduces material waste, and can significantly reduce construction time. It also promotes sustainability and can be more cost-effective in the long run.

What are the key steps involved in 3D printing a building?

The process of 3D printing a building involves creating a digital model using CAD software, selecting the appropriate material, and then using the 3D printer to deposit the material layer by layer according to the design specifications.

What is the potential of 3D printed building materials?

3D printed building materials have the potential to revolutionize the construction industry by offering customization, optimization, and the ability to create complex geometries. They allow for precise control over material distribution and result in highly efficient and robust structures.

Are there any examples of 3D printed houses?

Yes, there are several examples of 3D printed houses, including House Zero in Texas, Mighty Buildings in California, Project Milestone in the Netherlands, Tecla in Italy, and Kamp C in Belgium.

What are the advantages of 3D printed houses?

3D printed houses are more efficient and productive, reduce construction time and costs, and have environmental benefits such as minimizing material waste and reducing carbon footprint. They also offer design flexibility, allowing for unique and customized living spaces.