Which Plumbing Device Helps Prevent A Backflow

Introduction

Which Plumbing Device Helps Prevent A Backflow: Backflow is a potentially hazardous plumbing issue that occurs when contaminated water flows backward into a clean water supply system. It can lead to the contamination of drinking water, posing significant health risks to individuals and communities. To prevent this potentially dangerous situation, various plumbing devices have been developed and implemented. Among these devices, the backflow preventer stands out as a crucial component in maintaining the integrity and safety of water supply systems.

A backflow preventer is a plumbing device designed to protect against the reverse flow of water, ensuring that contaminated water cannot enter a clean water supply. It functions by allowing water to flow in one direction only, effectively preventing backflow and safeguarding the quality of the water supply. This device plays a vital role in residential, commercial, and industrial settings, where a reliable water supply is of paramount importance.

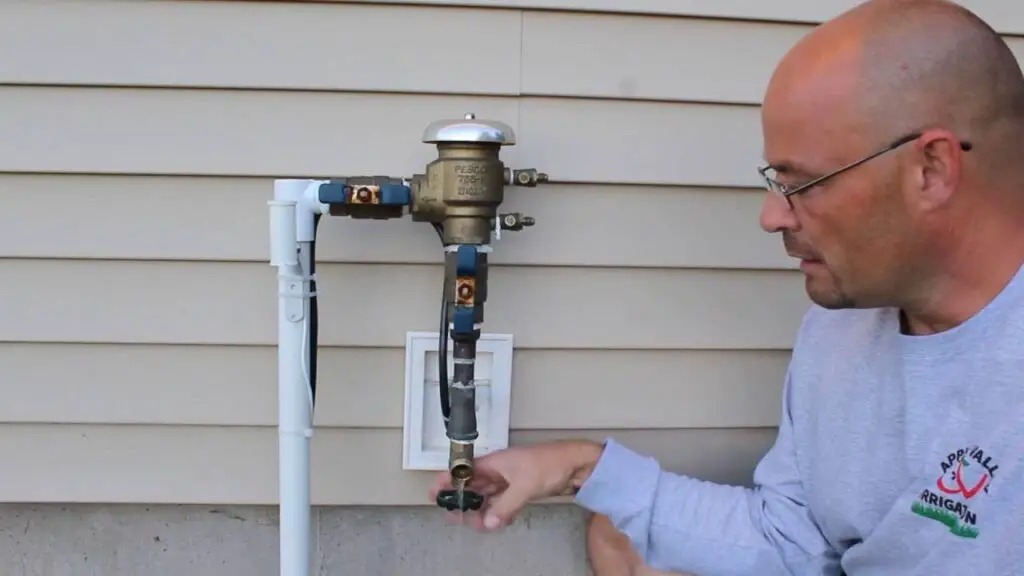

There are several types of backflow preventers available, each tailored to specific applications and levels of protection. Pressure vacuum breakers (PVBs) are commonly used to prevent backflow in irrigation systems. PVBs work by creating an air gap, which prevents water from flowing backward into the main water supply. These devices are relatively simple in design and operation, making them cost-effective and widely used.

A further variety of backflow preventers used in crucial settings is the reduced pressure zone (RPZ) assembly. Its RPZ has a set of check valves & a relief valve to stop water from reversing flow inside of it. Fire sprinkler systems and other commercial and industrial applications rely heavily on these devices for effective backflow protection.

What Valve Prevents Backflow Plumbing?

Check valves

A check valve provides a basic form of backflow prevention, preventing water from flowing in the wrong direction. National Fire Protection Association (NFPA) model codes and standards require them in various places on fire protection systems, and check valves are essential components of backflow preventers.

Backflow can cause problems with the potable water supply and perhaps lead to health problems. One-way valves are used in plumbing systems to restrict water flow to a single direction.The check valve is the most common type of valve used for this purpose.

Check valves, sometimes termed non-return or one-way valves, let fluid flow in one direction but not the other. A ball or disc opens to let water flow when inflow pressure exceeds outflow pressure. When flow direction changes or back pressure occurs, the mechanism shuts, preventing water from flowing in the wrong direction.

Water distribution systems employ check valves to avoid backflow. With check valves on sump pumps, sewage ejector systems, and draining systems, dirty water can’t get into the house. They prevent harmful substances like fertilizers and chemicals from seeping back into irrigation systems.

In order to avoid any unwanted backflow, check valves are frequently utilized in industrial settings. They are very important for keeping chemicals or other pollutants from getting into the water system or sensitive equipment. Safety gates Make sure that water can only go in one way and that dirty water doesn’t get into fire suppression systems.

Which Of The Following Is The Best Device For Preventing Backflow?

A pressure vacuum breaker or PVB is the most common type of backflow prevention devices. These spring operated valves constantly have water flowing through them.

When it comes to preventing backflow, choosing the best device depends on the specific requirements and characteristics of the plumbing system in question. However, among the available options, one device stands out as highly effective and widely used: the reduced pressure zone (RPZ) assembly.

One of the most dependable and sturdy backflow prevention devices is the RPZ assembly. It has a wide range of applications where stopping backflow is critical. The strict standards for backflow prevention in commercial, industrial, and fire sprinkler systems necessitate the usage of RPZ components.

The key advantage of an RPZ assembly lies in its design, which incorporates multiple check valves and a relief valve. This design avoids reverse flow and protects the water supply. The relief valve releases water and relieves assembly pressure if pressure drops or backflow occurs. This mechanism safeguards against contamination and provides a reliable barrier against backflow.

Another factor that contributes to the RPZ assembly’s effectiveness is its ability to provide protection even under adverse conditions. It is resistant to backflow from severely contaminated sources and can bear high pressure.This makes it suited for backflow-risky applications like chemical or hazardous industrial processes.

What Is A Backflow Valve In Plumbing?

Backflow prevention systems are devices installed onto a pipe that only allow water to flow in one direction. Think of it as a one-way gate that allows water from the city’s public water supply to flow into your home’s piping but stops water if and when it ever tries to flow backwards into the main water supply.

A backflow valve prevents water from flowing backward in plumbing systems. By preventing contaminated water from entering the clean water system, it protects the water supply.

Backflow occurs when there is a change in pressure in a plumbing system, causing the flow of water to reverse. A municipal water supply pressure dip, ruptured pipe, or siphoning effect might cause this reversal. Backflow from irrigation systems, sewage lines, or industrial activities can contaminate drinking water, creating serious health problems.

Water flows one way through a backflow valve, preventing backflow. When water flow reverses, check valves or mechanical devices close, preventing contaminated water from entering the clean water supply. Until the water flow is back to normal, the valve will stay closed.

Which Type Of Valve Allows Flow But Prevents Backflow?

Check valves

Check valves are one-way or nonreturn valves that open with fluid movement and pressure, and close to prevent backflow of the pressure to upstream equipment such as pumps and compressors. In fact, check valves allow the fluid to flow in only one direction.

Check valves have a disc or ball that opens for forward flow and closes for backflow. Fluid flows through the valve when inlet pressure exceeds output pressure. However, when the flow direction changes or back pressure occurs, the mechanism closes, effectively blocking the reverse flow of fluid.

Many different kinds of plumbing systems and applications make use of check valves to prevent backflow. Here are a few examples:

Residential Plumbing

Sump pumps have check valves to prevent water from returning to the basement during floods or drainage.

Irrigation Systems

In irrigation systems, check valves prevent tainted water from entering the main water supply.

Industrial Applications

In industrial settings, check valves are used to control the flow of gas or liquid while blocking its backwards movement.

Water Treatment Systems

Check valves are essential components in water treatment systems to prevent the backflow of treated water and maintain the integrity of the clean water supply.

Check valves come in various designs, including swing check valves, lift check valves, and ball check valves, among others. The specific design and configuration of the check valve may vary depending on the intended application and flow requirements.

What Is A Backflow Prevention Device?

A backflow prevention device is a product that ensures water can only flow in one direction. There are multiple types of backflow prevention devices, and they all work best in specific applications. All backflow preventers, no matter the type, protect clean water lines from wastewater contaminants.

A backflow prevention device is a crucial component in plumbing systems designed to protect the integrity and quality of the water supply by preventing the reverse flow of water. Its primary function is to prevent dangerous contaminants from tainting potable water supplies.

Backflow occurs when there is a change in pressure in a plumbing system, causing water to flow in the opposite direction. This reversal can happen due to various reasons, such as a drop in municipal water supply pressure, a burst pipe, or a siphoning effect. Backflow can introduce contaminants, such as chemicals, sewage, or pollutants, into the potable water supply, posing significant health risks.

Every single point in a plumbing system where backflow could occur requires a backflow prevention device. These devices work by utilizing check valves, mechanical devices, or air gaps that close or create barriers when water flow reverses, thus blocking the backflow of water and contaminants.

Are There Different Types Of Backflow Preventers?

These devices are specifically engineered to prevent the reverse flow of water and protect the integrity of the water supply.

Pressure Vacuum Breaker (PVB)

Irrigation systems frequently employ the usage of pressure vacuum breakers. It features a valve that creates an air gap between the water supply and the irrigation system. The air gap prevents backflow by allowing atmospheric air to enter the system when there is a drop in pressure, thus preventing the contamination of the water supply.

Double Check Valve Assembly (DCVA)

Residential & commercial plumbing use DCVAs. They consist of two check valves arranged in series. These check valves allow water to flow in one direction only, preventing backflow. The double protection of two check valves provides a higher level of protection against backflow.

Reduced Pressure Zone (RPZ) Assembly

Industrial settings and fire suppression systems frequently use RPZ components because of their superior safety. They include multiple check valves and a relief valve. The check valves prevent the reverse flow of water, while the relief valve opens to release water if there is a drop in pressure or a potential backflow situation. RPZ assemblies provide a comprehensive barrier against backflow and are suitable for applications with a high risk of contamination.

Atmospheric Vacuum Breaker (AVB)

Water systems use AVBs on hose bibs & sprinkler heads. They feature a check valve and an air inlet valve that allows air to enter the system when there is a drop in pressure, preventing backflow.

Spill-resistant Vacuum Breaker (SVB)

SVBs see widespread application in professional settings, such as hospitals and spas. They provide protection against backflow by incorporating a check valve and an air inlet valve that prevents backflow while allowing air to enter the system.

Each type of backflow preventer has its own specific design and functionality, making it suitable for particular applications and levels of protection. It is important to consult with a qualified professional to determine the appropriate type of backflow preventer based on the specific requirements and regulations of the plumbing system. Regular maintenance and testing of backflow preventers are essential to ensure their proper functioning and reliability.

Where Are Backflow Preventers Commonly Used?

Backflow preventers are commonly used in various settings where protecting the integrity of the water supply is crucial. These devices are essential in preventing the reverse flow of water and the potential contamination of clean water sources. Some of the common applications and locations where backflow preventers are commonly used include:

Residential Plumbing

Protecting the drinking water supply necessitates the installation of backflow preventers in household plumbing systems. You can find them in your home if you have an irrigation system, a pool, or a cross-connection to a water source that isn’t safe to drink.

Commercial Buildings

Office buildings, hotels, shopping centers, and restaurants are just some of the many commercial establishments that make use of backflow preventers. They avoid contamination from fire sprinklers, boilers, and cooling towers that reuse water. Commercial buildings often have complex plumbing systems with multiple potential sources of backflow, making backflow preventers essential for maintaining water quality.

Industrial Facilities

Backflow preventers are vital in industrial facilities where there is a high risk of water contamination. It may be necessary to separate the wastewater and other contaminants from the potable water supply at these sites. To stop these contaminants from getting into the drinking water supply, backflow preventers are set up.

Irrigation Systems

Irrigation systems typically have backflow preventers installed to keep polluted water from entering the mains supply. Clean water is protected against contamination by installing these devices at the point of connection between the irrigation system and the main water supply.

Fire Protection Systems

Backflow preventers are crucial components of fire sprinkler systems. They prevent the backflow of water or firefighting agents into the main water supply. This ensures that the water used for fire protection remains separate from the potable water supply, preventing contamination.

It is important to note that the specific regulations and requirements for backflow prevention may vary depending on local plumbing codes and standards. Consulting with a qualified plumber or plumbing engineer is essential to determine the appropriate type and installation of backflow preventers based on the specific needs of each application and the local regulations in place.

Why Is Backflow A Concern In Plumbing Systems?

Backflow is a significant concern in plumbing systems due to the potential contamination of clean water supplies, which can pose serious health risks to individuals and communities. Here are some key reasons why backflow is a concern:

Contamination of Drinking Water

Backflow can introduce harmful substances, such as chemicals, pesticides, bacteria, or sewage, into the potable water supply. Consuming or using contaminated water can lead to various health issues, including gastrointestinal problems, infections, and even long-term illnesses.

Cross-Connections

Cross-connections occur when there is a connection between a potable water system and a non-potable water source or a contaminated system. Backflow can occur through these connections, allowing contaminants to flow back into the clean water supply. Cross-connections can exist in various settings, including residential homes, commercial buildings, and industrial facilities, making it crucial to prevent backflow to maintain water safety.

Legal and Regulatory Compliance

Backflow prevention is mandated by plumbing codes and regulations in many jurisdictions. Compliance with these regulations is essential to ensure the safety and quality of the water supply. Failure to install and maintain appropriate backflow prevention devices can result in legal consequences and potential liabilities for property owners and operators.

Protection of Public Health

Backflow prevention is a fundamental aspect of safeguarding public health. Communities rely on clean and uncontaminated water supplies for drinking, cooking, bathing, and other daily activities. Preventing backflow helps protect individuals and communities from waterborne diseases and potential outbreaks.

Environmental Impact

Backflow can also have negative environmental consequences. Contaminated water flowing back into the environment can harm ecosystems, aquatic life, and vegetation. Preventing backflow helps maintain the ecological balance and protects natural water sources.

Conclusion

The plumbing device that plays a crucial role in preventing backflow is the backflow preventer. Backflow is a serious concern as it can contaminate clean water supplies, leading to significant health risks. A backflow preventer acts as a barrier, ensuring that water flows in one direction only and preventing the reverse flow of water and contaminants.

Various types of backflow preventers are available to suit different applications and levels of protection. These include pressure vacuum breakers (PVBs), double check valve assemblies (DCVAs), and reduced pressure zone (RPZ) assemblies. Each type of backflow preventer is designed with specific mechanisms to block backflow and maintain the integrity of the water supply.

Backflow preventers are commonly used in residential, commercial, and industrial settings, as well as in irrigation systems and fire protection systems. They are installed at strategic points in the plumbing system to safeguard against potential sources of contamination, such as irrigation systems, cross-connections, or industrial processes. By utilizing check valves, mechanical devices, or air gaps, backflow preventers ensure that water flows in one direction only, protecting the health and safety of individuals and communities.