Revolutionizing Construction: Lightweight Building Materials

As a professional copywriting journalist, I am delighted to share with you the latest advancements in lightweight building materials and their impact on modern construction. These innovative materials offer sustainable solutions that not only enhance the efficiency of construction processes but also contribute to a more eco-friendly approach. From reducing energy consumption to improving structural integrity, lightweight building materials are revolutionizing the way buildings are designed and constructed.

Key Takeaways:

- Lightweight building materials are transforming modern construction practices.

- These materials offer sustainable and eco-friendly solutions.

- Advancements in materials science have led to the development of innovative options.

- Lightweight construction materials enhance energy efficiency and reduce environmental impact.

- They provide improved structural integrity, thermal insulation, and aesthetic appeal.

Innovative Materials: Solving Past Problems

When it comes to construction, cracked concrete has always been a major concern. Not only does it compromise the structural integrity of a building, but the repairs can also be costly and time-consuming. However, with the development of innovative materials, such as self-healing concrete, a solution to this problem may have been found.

Self-healing concrete incorporates bacteria, polymers, or enzymes into the concrete mix, which can automatically fill and repair cracks. These materials release substances that react with water, effectively sealing the cracks and restoring the strength of the concrete. This not only saves time and money but also extends the lifespan of concrete structures.

But self-healing concrete is not the only innovative material making waves in the construction industry. Other materials like transparent wood, carbon fiber, and aerogel offer unique properties that enhance the possibilities for modern construction. Transparent wood, for example, is five times stronger and lighter than glass, offering excellent thermal efficiency and lower production costs compared to traditional materials.

Table: Comparison of Innovative Construction Materials

| Material | Strength | Weight | Thermal Efficiency | Cost |

|---|---|---|---|---|

| Self-healing concrete | High | Comparable to traditional concrete | Comparable to traditional concrete | Comparable to traditional concrete |

| Transparent wood | Five times stronger than glass | Lightweight | Excellent | Lower production costs compared to glass |

| Carbon fiber | Exceptional | 75% lighter than iron, 30% lighter than aluminum | Excellent | Higher cost compared to traditional materials |

| Aerogel | Lightest and strongest material | Ultralight | Excellent | Higher cost compared to traditional materials |

These innovative construction materials are paving the way for the future of construction. With their unique properties and benefits, they offer sustainable solutions to long-standing problems in the industry. As researchers continue to refine and develop these materials, we can expect to see even more groundbreaking innovations that will shape the way buildings are designed and constructed.

Transparent Wood: A Sustainable Alternative

Transparent wood is a recent eco-friendly innovation in construction materials. It offers a promising alternative to traditional glass windows and panels, providing a unique combination of strength, durability, and transparency. This sustainable material is created by treating thin strips of wood with a special solution and epoxy resin, resulting in a stable and transparent material that is five times stronger and lighter than glass.

One of the key advantages of transparent wood is its sustainability. It is made from the fast-growing balsa tree, which is a renewable resource. In contrast, the production of glass involves high energy consumption and has a significant carbon footprint. Furthermore, transparent wood has significantly lower production costs compared to glass, making it an economically viable choice for construction projects. Its thermal efficiency properties also contribute to energy savings and reduced carbon emissions.

Transparent wood is a sustainable and eco-friendly material that offers strength, durability, and transparency. Made from renewable balsa trees and with lower production costs compared to glass, it presents a viable and environmentally conscious choice for modern construction.

The applications of transparent wood in construction are vast. From windows and doors to façades and interior partitions, transparent wood can provide natural light while maintaining a sense of privacy. Additionally, it offers excellent thermal insulation properties, contributing to energy-efficient building designs. Its unique aesthetics add a touch of elegance and natural beauty to any architectural project, making it a popular choice among environmentally conscious designers and builders.

Advantages of Transparent Wood:

- Eco-friendly and sustainable

- Strength and durability

- Transparency and natural light

- Lower production costs compared to glass

- Excellent thermal insulation properties

- Unique aesthetics

As the construction industry continues to prioritize sustainability and energy efficiency, transparent wood is emerging as a promising solution. Its combination of strength, transparency, and eco-friendliness makes it an attractive alternative to traditional building materials. With ongoing advancements in transparent wood technology, we can expect to see even more innovative applications and architectural designs that integrate this sustainable material in the future.

Carbon Fiber: Strength and Lightness Combined

Carbon fiber is a game-changing material in modern construction, offering a unique combination of strength and lightness. With its exceptional properties, carbon fiber is revolutionizing the way buildings are reinforced and panels are constructed.

The key advantage of carbon fiber is its light weight, as it is 75% lighter than iron and 30% lighter than aluminum. This makes it an ideal material for lightweight reinforcement in traditional building structures. By incorporating carbon fiber into concrete, steel, or timber elements, the overall weight of the structure can be significantly reduced, leading to more efficient use of materials and increased flexibility in design.

“Carbon fiber reinforcement provides excellent thermal insulation, making it a valuable addition to modern construction.”

In addition to its lightness, carbon fiber offers exceptional strength, surpassing that of traditional building materials. Its high tensile strength makes it an effective solution for reinforcing structural components and improving overall stability. Moreover, carbon fiber reinforcement provides excellent thermal insulation properties, helping to regulate temperature and reduce energy consumption in buildings.

Enhancing Construction Efficiency

While carbon fiber offers numerous benefits, its high cost remains a challenge for widespread application in the construction industry. However, ongoing research and advancements in manufacturing techniques are driving down production costs, making carbon fiber a more feasible option for a broader range of projects in the future.

Overall, carbon fiber represents a significant advancement in lightweight construction materials. Its combination of strength, lightness, and thermal insulation properties provides architects and engineers with new possibilities for innovative and sustainable building design. As the construction industry continues to prioritize energy efficiency and environmental sustainability, carbon fiber will play a crucial role in shaping the future of construction.

| Advantages of Carbon Fiber in Construction |

|---|

| Lightweight reinforcement |

| Exceptional strength |

| Thermal insulation properties |

| Flexibility in design |

| Potential for energy savings |

Self-Healing Concrete: A Game-Changer

The construction industry has long grappled with the challenge of concrete cracking, which compromises the structural integrity of buildings and requires costly repairs. However, the development of self-healing concrete has emerged as a groundbreaking solution. By incorporating innovative technologies such as bacterial capsules, polymers, or enzymes into the concrete mix, cracks can now be automatically repaired.

Self-healing concrete works through a simple yet ingenious process. The embedded bacteria or capsules remain dormant until cracks appear in the concrete. Once exposed to water from the crack, the bacteria or capsules release substances that react with the water and form a solid material, effectively filling and sealing the cracks. This automatic repair mechanism not only saves time and money but also extends the lifespan of concrete structures.

“Self-healing concrete represents a significant advancement in construction technology. By harnessing the power of nature, we are able to create more resilient and durable concrete structures. This technology has the potential to revolutionize the industry and reduce the need for frequent repairs and maintenance.”

The Benefits of Self-Healing Concrete

Self-healing concrete offers several benefits that make it a game-changer in the construction industry. Firstly, it improves the overall durability and longevity of concrete structures. The automatic repair mechanism prevents small cracks from developing into larger ones, ensuring that the structural integrity is maintained over time.

Secondly, self-healing concrete reduces the need for costly and disruptive repairs. By repairing cracks as they occur, it eliminates the need for manual intervention and expensive maintenance procedures. This not only saves money but also minimizes the inconvenience caused to building occupants.

Lastly, self-healing concrete contributes to sustainability efforts in the construction industry. By reducing the need for frequent repairs and replacements, it helps conserve resources and reduce waste. Additionally, the use of eco-friendly materials, such as bacterial capsules, aligns with the growing demand for sustainable construction practices.

| Benefits of Self-Healing Concrete | |

|---|---|

| Improved durability and longevity of concrete structures | |

| Reduction in costly and disruptive repairs | |

| Contribution to sustainability in the construction industry |

Aerogel: The Lightest and Strongest Material

Aerogel is an ultralight material that has garnered significant attention in the construction industry due to its remarkable properties. It is derived from a gel and consists of 99.8% air, making it incredibly lightweight. Despite its low density, aerogel is also one of the strongest materials known to man, capable of withstanding high levels of compression and tension.

One of the key advantages of aerogel is its exceptional thermal insulation properties. It boasts an extremely low thermal conductivity, making it highly effective in preventing heat transfer. This makes aerogel an ideal choice for applications where thermal insulation is crucial, such as in the construction of energy-efficient buildings. By incorporating aerogel into the building envelope, the heat loss can be significantly reduced, leading to lower energy consumption and enhanced comfort for occupants.

“Aerogel is the lightest and strongest material in the world, with extremely low density and thermal conductivity.”

In addition to its thermal insulation capabilities, aerogel also possesses excellent soundproofing qualities. With its porous structure, it can effectively absorb and dissipate sound waves, reducing noise transmission between different areas of a building.

Applications of Aerogel in Construction

Aerogel has various applications in the construction industry. It can be used as insulation material in roofs, walls, and windows to improve energy efficiency. Additionally, aerogel can be integrated into structural elements to enhance their strength and durability. Its lightweight nature also allows for easier handling and installation, reducing construction time and costs.

Furthermore, aerogel has found use in the field of environmental protection. It can act as a collecting matrix for dust particles, making it effective for air filtration systems. Aerogel-based filters can purify air by capturing pollutants and improving indoor air quality.

| Advantages of Aerogel | Applications |

|---|---|

| Ultralight and strong | Insulation in roofs, walls, and windows |

| Excellent thermal insulation | Structural enhancement |

| Superior soundproofing | Environmental protection: air filtration |

Aerogel is a versatile material that has the potential to revolutionize the construction industry. Its combination of ultralight weight, exceptional strength, and thermal insulation properties make it an attractive choice for sustainable and energy-efficient buildings. As research and development in aerogel continue, we can anticipate even more innovative solutions and applications emerging in the future.

Richlite: From Waste Paper to Durable Material

Richlite is a remarkable paper composite material that has gained popularity in the construction industry for its durability, versatility, and eco-friendly properties. Made from waste paper, Richlite offers a sustainable alternative to traditional building materials while providing exceptional performance in various applications. One of its key features is its water resistance, making it suitable for both interior and exterior use.

With its low moisture absorption, Richlite is resistant to warping, rotting, and degradation, making it an excellent choice for areas prone to moisture and humidity. This material can be easily processed, milled, and joined, providing architects and designers with endless possibilities in terms of shape, texture, and color. Whether used as countertops, wall cladding, furniture, or even musical instruments, Richlite offers a unique blend of aesthetic appeal and long-lasting durability.

Applications of Richlite:

- Countertops and kitchen surfaces

- Wall cladding and paneling

- Furniture, including tables, chairs, and cabinets

- Exterior siding and façades

- Decking and outdoor flooring

- Instrument manufacturing

Richlite is not only a sustainable choice but also a material that offers exceptional strength, heat resistance, and a distinctive look. Its unique combination of attributes positions it as a versatile solution for both residential and commercial projects.

Architects and designers appreciate Richlite for its aesthetic appeal, as it comes in a variety of colors and finishes, ranging from natural wood tones to vibrant hues. Its smooth and matte texture adds a touch of sophistication to any space while providing a tactile experience. Moreover, Richlite is easily maintained and cleaned, requiring minimal effort to keep its beauty intact for years to come.

| Advantages of Richlite | Applications |

|---|---|

| Water resistance | Countertops and kitchen surfaces |

| Durability | Wall cladding and paneling |

| Resistance to decay | Furniture |

| Easy to process and join | Exterior siding and façades |

| Variety of colors and finishes | Decking and outdoor flooring |

| Sustainable material | Instrument manufacturing |

In conclusion, Richlite is a remarkable paper composite material that offers a sustainable and durable solution for various construction and design applications. Its water resistance, durability, and versatility make it an excellent choice for countertops, wall cladding, furniture, and more. With its unique combination of attributes, Richlite provides architects and designers with the opportunity to create beautiful and environmentally conscious spaces.

Liquid Granite: A Versatile Construction Mixture

When it comes to construction materials, liquid granite stands out as a solid and durable option. Made from a combination of marble chips, additives, and decorative fillers, this unique construction mixture offers a range of benefits for various applications. One of its main advantages is its ability to create a solid and durable seal when sprayed onto surfaces like concrete, brickwork, stone, or asphalt. Acting as a surface sealant, liquid granite provides protection against environmental impacts and enhances the longevity of the construction.

What makes liquid granite particularly versatile is its ability to be customized. Whether you want to achieve a smooth, textured, or patterned finish, liquid granite can be tailored to meet your design preferences. With a wide range of colors and textures available, this construction mixture offers endless possibilities for creating visually appealing surfaces that meet both functional and aesthetic requirements.

“Liquid granite is a game-changer in the construction industry. Its ability to create a solid and durable seal provides long-lasting protection for various surfaces. Whether it’s for decorative finishes or protective coatings, liquid granite offers versatility and customization options that traditional materials cannot match.”

Surface Sealant Properties

The surface sealant properties of liquid granite make it an excellent choice for a range of construction projects. Not only does it provide protection against environmental factors such as moisture, UV rays, and chemical exposure, but it also enhances the overall durability of the surfaces it is applied to. By creating a strong and resilient seal, liquid granite helps to prevent cracks, chips, and other forms of damage, prolonging the lifespan of the underlying structure.

| Benefits of Liquid Granite: | Applications: |

|---|---|

| Superior durability | Concrete surfaces |

| Resistance to environmental impacts | Brickwork |

| Protection against moisture and UV rays | Stone surfaces |

| Customizable colors and textures | Asphalt |

| Enhanced longevity |

From decorative finishes to protective coatings, liquid granite offers a versatile solution for various surfaces. Its solid and durable properties, combined with a customizable appearance, make it a go-to choice for architects, contractors, and designers seeking long-lasting and visually appealing results. With its wide range of applications and benefits, liquid granite continues to shape the future of construction materials.

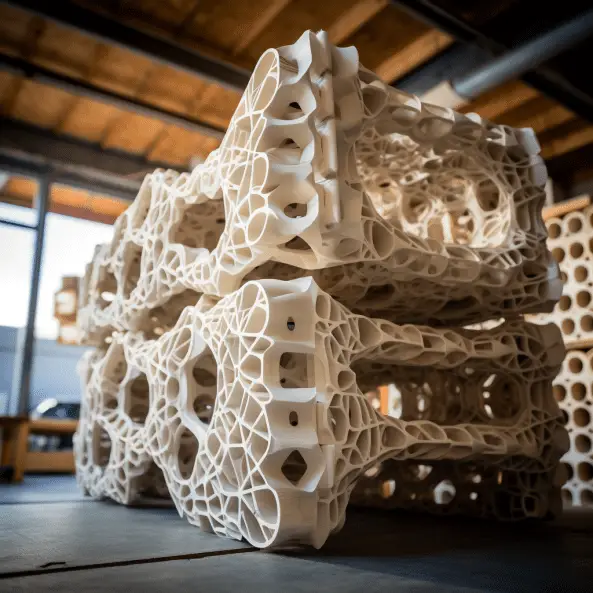

Allusion Panels: Lightweight Cladding with Various Applications

Allusion panels, made from stabilized aluminum foam, are a versatile and innovative solution for lightweight cladding in modern construction projects. These panels offer a range of unique features and applications, making them an excellent choice for architects and builders.

One of the standout properties of allusion panels is their lightweight nature. Being made from aluminum foam, they are significantly lighter than traditional cladding materials, reducing the overall weight of the building. This not only makes transportation and installation easier, but also allows for greater design flexibility and possibilities.

Additionally, allusion panels provide excellent soundproofing capabilities. The unique composition of aluminum foam helps to dampen sound vibrations, making them an ideal choice for spaces where noise reduction is important. Whether it’s in commercial buildings, residential complexes, or even concert halls, allusion panels can contribute to a more comfortable and peaceful environment.

Applications of Allusion Panels

Allusion panels have a wide range of applications in construction and architecture. They can be used as wall panels, facades, ceilings, floorings, signages, and even light fixtures. Their lightweight nature and versatile properties make them suitable for various design styles and construction requirements.

| Application | Benefits |

|---|---|

| Wall Panels | Lightweight, soundproofing, easy installation |

| Facades | Energy-efficient, weather-resistant, aesthetic appeal |

| Ceilings | Soundproofing, fire-resistant, customizable design |

| Floorings | Durable, low maintenance, impact-resistant |

| Signages | Lightweight, weather-resistant, easy customization |

| Light Fixtures | Creative design possibilities, lightweight, energy-efficient |

These are just a few examples of how allusion panels can be utilized in construction. Their versatility, durability, and aesthetic appeal make them a popular choice among architects and builders looking to create modern, sustainable, and visually striking buildings.

Innovative Façade Solutions: From Spacer Tapes to Bonding Tapes

When it comes to modern construction, façade solutions play a crucial role in ensuring structural integrity, energy efficiency, and aesthetics. One of the key elements in lightweight façade constructions is the use of spacer tapes. These tapes are essential for bonding stiffener bars to claddings, providing extra stiffness and secure attachment. An excellent option in the market is Norbond Bonding Tapes, known for their high-quality performance and reliability.

Norbond Spacer Tapes simplify the assembly process, ensuring optimal curing and robust bonding between the structural components. These tapes are designed to withstand external forces, such as wind loads, while maintaining the integrity of the building envelope. They contribute to the overall structural stability of lightweight façades, enhancing their resistance to deformation and ensuring long-term durability.

In addition to spacer tapes, bonding tapes also play a significant role in lightweight construction. Norbond Bonding Tapes are commonly used for panel tacks, providing exceptional holding power and facilitating the construction of lightweight structures with high-performance cladding systems. These tapes offer a reliable and efficient solution for bonding different materials, from glass to metal, ensuring a secure and aesthetic finish.

The combination of spacer tapes and bonding tapes in façade solutions enables architects and builders to achieve innovative and efficient designs. Whether it’s for structural glazing, curtain walls, or ventilated facades, these innovative tapes provide the necessary support and bonding properties required for lightweight construction. With their reliable performance and ease of use, Norbond Bonding Tapes have become a go-to solution for architects and builders seeking high-quality façade solutions.

The Benefits of Lightweight Construction

Lightweight construction offers numerous benefits for modern construction projects. By utilizing lightweight building materials, several advantages can be achieved, including lower energy consumption, enhanced comfort, and improved sustainability. These benefits make lightweight construction an attractive option for architects, builders, and homeowners alike.

Lower Energy Consumption: One of the significant advantages of lightweight construction is its ability to reduce energy consumption. Lightweight building materials typically have lower embodied energy, meaning less energy is required in their production and transportation. Additionally, these materials offer improved thermal insulation, reducing the need for excessive heating or cooling, which can significantly lower energy usage over time.

Enhanced Comfort: Lightweight construction materials provide excellent thermal and acoustic insulation, leading to enhanced comfort and well-being for occupants. These materials can effectively regulate indoor temperature, keeping the interiors cooler in hot climates and warmer in cold climates. Additionally, they offer superior soundproofing capabilities, minimizing external noise and creating a peaceful and comfortable living environment.

Sustainability: Lightweight construction promotes sustainability by adopting materials with lower environmental impacts. The use of lightweight building materials reduces the demand for traditional resource-intensive materials, such as concrete and steel, which contribute significantly to carbon emissions. Furthermore, the lightweight nature of these materials allows for easier transportation and prefabrication, resulting in reduced fuel consumption and construction waste.

| Benefits of Lightweight Construction |

|---|

| Lower Energy Consumption |

| Enhanced Comfort |

| Sustainability |

Overall, lightweight construction offers a range of benefits that positively impact energy efficiency, occupant comfort, and environmental sustainability. By incorporating lightweight building materials into construction projects, developers can create structures that are not only aesthetically pleasing but also sustainable, comfortable, and cost-effective.

Conclusion

In conclusion, lightweight construction materials are paving the way for a sustainable future in the construction industry. These materials offer a range of benefits, including reduced energy consumption, enhanced comfort, and lower environmental impact. By utilizing innovative solutions like self-healing concrete, transparent wood, carbon fiber, and aerogel, architects and builders can create structures that are not only aesthetically pleasing but also durable and energy-efficient.

The future of construction lies in the continued development and application of lightweight materials. As advancements in materials science continue, we can expect to see even more innovative solutions emerge. These materials will not only enhance the efficiency and sustainability of buildings but also contribute to the overall well-being of occupants.

With the increasing focus on sustainability and the growing demand for eco-friendly construction practices, lightweight construction is positioned to play a crucial role in shaping the future of the industry. By embracing these sustainable solutions, we can create buildings that meet the evolving needs of society while minimizing our impact on the environment.

FAQ

What are lightweight building materials?

Lightweight building materials are materials that offer sustainable, efficient, and cost-effective solutions for modern construction. These materials are environmentally friendly, reliable, and durable while also being lightweight and easy to install.

What is self-healing concrete?

Self-healing concrete is a type of concrete that incorporates bacteria, polymers, or enzymes into the mix. These substances react with water and automatically fill and repair cracks in the concrete, saving both time and money on costly repairs.

What is transparent wood?

Transparent wood is an eco-friendly innovation in construction materials. It is created by treating thin strips of wood with a special solution and epoxy resin, resulting in a stable and transparent material that is stronger and lighter than glass.

What is carbon fiber?

Carbon fiber is a lightweight material that offers exceptional strength and durability. It is 75% lighter than iron and 30% lighter than aluminum, making it ideal for reinforcing traditional building materials and reducing weight in panels.

How does self-healing concrete work?

Self-healing concrete incorporates bacteria, polymers, or enzymes into the mix. When the concrete cracks, the bacteria or capsules release substances that react with water, fill the cracks, and restore the concrete’s strength, saving the need for costly repairs.

What is aerogel?

Aerogel is a synthetic porous material derived from a gel and is 99.8% air. It is the lightest and strongest material in the world, with extremely low density and thermal conductivity. It is widely used for thermal insulation in construction.

What is Richlite?

Richlite is a paper composite material made from waste paper. It is a durable and versatile material that is water-resistant, hygienic, and has low moisture absorption. It is suitable for various applications in construction and furniture design.

What is liquid granite?

Liquid granite is a construction mixture made of marble chips, additives, and decorative fillers. When sprayed onto surfaces like concrete, brickwork, stone, or asphalt, it creates a solid and durable seal, providing protection and enhancing the longevity of the construction.

What are allusion panels?

Allusion panels are lightweight cladding made from stabilized aluminum foam. They offer unique features such as soundproofing, durability, fire resistance, and ease of installation, making them suitable for various applications in construction and architecture.

What are innovative facade solutions?

Innovative facade solutions include spacer tapes and bonding tapes. Spacer tapes are used to bond stiffener bars to claddings, providing extra stiffness and secure attachment. Bonding tapes are used for panel tacks, offering exceptional holding power and facilitating the construction of lightweight structures with high-performance cladding systems.

What are the benefits of lightweight construction?

Lightweight construction offers numerous benefits, including reduced carbon footprint, improved energy efficiency, enhanced thermal and acoustic insulation, streamlined processes, reduced costs, and promotion of sustainable practices.