Redefining Construction: Composite Building Materials

Composite building materials are a key component of advanced construction practices. These materials are engineered from two or more different materials, each with its own unique properties, resulting in high-performing building materials that offer exceptional strength, durability, and versatility.

Examples of composite building materials include concrete, reinforced plastics, cement, steel-reinforced concrete, and composite wooden beams. These materials have revolutionized modern construction by providing improved performance, greater design flexibility, and enhanced resistance to various environmental factors. Understanding the characteristics of composite materials is crucial when choosing the right building material for a specific project.

Key Takeaways:

- Composite building materials are engineered from two or more different materials, resulting in high-performing building materials.

- Examples of composite building materials include concrete, reinforced plastics, cement, steel-reinforced concrete, and composite wooden beams.

- There are different types of composite materials, such as reinforced plastics, thermoset plastics, and thermoplastics, each with its own unique characteristics.

- Composite building materials offer advantages such as durability, strength, and resistance to rot, insects, and moisture.

- However, it’s important to consider the disadvantages of composite materials, such as fading due to UV light exposure or deterioration over time.

Types of Composite Building Materials

Composite building materials encompass a wide range of products. Some common types of composite materials include reinforced plastics, thermoset plastics, and thermoplastics.

Reinforced plastics: These materials are plastic materials that have been reinforced with fibrous material such as fiberglass. They offer excellent strength and durability, making them suitable for various construction applications.

Thermoset plastics: These materials undergo a curing process that creates an irreversible chemical bond, making them highly heat resistant and strong. They are commonly used in environments that require high temperature stability.

Thermoplastics: Unlike thermoset plastics, thermoplastics can be remolded without affecting the material’s physical properties. They offer flexibility and easy processing, making them a popular choice in construction projects.

Table: Comparison of Composite Building Materials

| Types of Composite Materials | Common Applications | Advantages |

|---|---|---|

| Reinforced Plastics | Structural components, tanks, pipes | Durable, lightweight, high strength |

| Thermoset Plastics | Aerospace parts, electrical insulators | Heat resistant, strong, chemical resistant |

| Thermoplastics | Automotive parts, packaging materials | Flexible, easy processing, recyclable |

Reinforced plastics offer excellent strength and durability, making them suitable for various construction applications. Thermoset plastics are highly heat resistant and strong, making them ideal for environments that require high temperature stability. Thermoplastics, on the other hand, offer flexibility and easy processing, making them a popular choice in construction projects.

When selecting the right composite building material, it is essential to consider the specific properties and durability of each type. The table above provides a comparison of the common types of composite materials, their applications, and advantages, which can help guide the decision-making process.

Composite Building Materials: Pros and Cons

Composite building materials have gained significant popularity in the construction industry due to their unique properties and advantages. However, it is also essential to consider the limitations and disadvantages of these materials when making informed decisions for construction projects. Below, I will outline the pros and cons of composite building materials.

Advantages of Composite Building Materials

- Durability: Composite materials are known for their exceptional durability and long lifespan. They can withstand harsh weather conditions, including extreme temperatures, moisture, and UV exposure.

- Strength: Composite building materials offer excellent strength-to-weight ratios, making them lightweight yet strong. This factor is particularly advantageous in applications that require high load-bearing capacities.

- Resistance: Composite materials are highly resistant to rot, insects, and moisture, making them suitable for outdoor or humid environments. They do not warp, crack, or splinter like traditional building materials.

- Aesthetics: Composite materials can be designed to resemble natural wood, offering a visually appealing option for projects that require the appearance of real wood without the maintenance associated with it.

Disadvantages of Composite Building Materials

- Fading: Some composite materials, particularly those containing PVC, may fade when exposed to prolonged UV light exposure. This issue can affect the overall appearance of the material over time.

- Moisture and UV Sensitivity: Certain composite materials, especially those reinforced with wood fibers, may be susceptible to moisture absorption and UV degradation. This can lead to material breakdown and deterioration over time.

- Care and Maintenance: Composite materials may require specific care and maintenance procedures to ensure their longevity. Regular cleaning, sealing, and protection against harsh chemicals may be necessary to preserve their appearance and performance.

- Cost: Composite building materials can be more expensive upfront compared to traditional materials. However, it is essential to consider the long-term benefits and durability they offer, which can offset the initial investment.

| Advantages | Disadvantages |

|---|---|

| Durability | Fading |

| Strength | Moisture and UV Sensitivity |

| Resistance | Care and Maintenance |

| Aesthetics | Cost |

In summary, composite building materials offer numerous advantages such as durability, strength, resistance, and aesthetic appeal. However, potential disadvantages including fading, moisture and UV sensitivity, maintenance requirements, and initial cost should be carefully considered. By weighing the pros and cons, construction professionals can make informed decisions when selecting composite building materials for their projects.

Composite 3D Printing Materials

Composite 3D printing is a cutting-edge technology that combines the benefits of composite materials with the versatility of additive manufacturing. It involves using a combination of at least two different components, such as carbon fiber, fiberglass, or Kevlar, mixed with a plastic matrix, to create complex 3D printed objects. This fusion of materials allows for the production of parts with enhanced mechanical properties, durability, and strength.

Carbon fiber is a popular choice for composite 3D printing due to its exceptional strength-to-weight ratio. It provides excellent stiffness and lightweight properties, making it ideal for applications in aerospace, automotive, and other industries where weight reduction is crucial. Fiberglass and Kevlar are also used as reinforcements for thermoplastic polymers, offering improved mechanical and thermal resilience.

“Composite 3D printing technology enables us to create parts with superior performance and tailored properties. By combining different materials, we can achieve a level of design flexibility and functionality that was previously unattainable.”

The versatility of composite 3D printing materials makes them suitable for various industries and applications. The automotive industry benefits from the exceptional strength and durability of composites for producing lightweight and high-performance parts. Additionally, composite 3D printing materials find applications in construction, healthcare, and consumer goods, among others.

Table: Comparison of Composite 3D Printing Materials

| Material | Strength | Weight | Applications |

|---|---|---|---|

| Carbon Fiber | High | Lightweight | Aerospace, automotive, sports equipment |

| Fiberglass | Good | Lightweight | Engineering prototypes, marine applications |

| Kevlar | High | Lightweight | Automotive, defense, industrial |

In conclusion, composite 3D printing materials offer a range of advantages in terms of strength, weight reduction, and design flexibility. With the ability to combine different materials, such as carbon fiber, fiberglass, and Kevlar, with plastic matrices, this technology opens up new possibilities for creating parts with superior performance and tailored properties. As the field of composite 3D printing continues to advance, we can expect even more exciting developments and applications in various industries.

Carbon Fiber Reinforced Composite Materials

Carbon fiber reinforced composite materials are at the forefront of innovation in the construction industry. Combining the exceptional strength and stiffness of carbon fiber with the versatility of composite materials, these composites offer a range of benefits for various applications. The unique properties of carbon fiber composites make them ideal for lightweight yet sturdy structures, making them highly sought after in industries such as aerospace, automotive, and construction.

This combination provides excellent tensile strength, making it suitable for manufacturing end parts that require high performance and durability. Carbon fiber reinforced composite materials also offer exceptional resistance to corrosion, impact, and fatigue, making them well-suited for demanding environments.

Applications of Carbon Fiber

- Aerospace: Carbon fiber reinforced composites are extensively used in the aerospace industry to manufacture components such as wings, fuselages, and interior structures. The high strength-to-weight ratio of carbon fiber allows for fuel efficiency and improved performance in aircraft.

- Automotive: Carbon fiber composites are increasingly utilized in the automotive sector to produce lightweight and fuel-efficient vehicles. Carbon fiber components can enhance the overall strength and rigidity of the vehicle while reducing its weight, thereby improving fuel economy and performance.

- Construction: Carbon fiber reinforced composites find applications in construction projects that require high-strength materials. They are used in the construction of bridges, buildings, and infrastructure to enhance structural integrity and durability.

“Carbon fiber reinforced composite materials offer superior strength, lightweight design, and resistance to environmental factors, making them valuable in various industries.”

The versatility and performance of carbon fiber reinforced composite materials continue to drive advancements in the construction industry. Ongoing research and development aim to further improve the properties of carbon fiber composites and explore new applications. As technology progresses, carbon fiber reinforced composite materials will play a crucial role in shaping the future of building, enabling more sustainable, efficient, and durable construction practices.

| Advantages | Disadvantages |

|---|---|

| Exceptional strength and stiffness | Tendency to delaminate under impact |

| Lightweight design | High production cost |

| Resistance to corrosion and fatigue | Susceptible to UV degradation |

Fiberglass Reinforced Composite Materials

Fiberglass reinforced composite materials are widely used in various industries due to their commendable mechanical properties. When combined with thermoplastic polymers, fiberglass can yield parts that are ten times stronger than ABS, making it an excellent choice for engineering prototypes and end-use parts. Unlike carbon fiber composites, fiberglass composites exhibit less rigidity and brittleness, offering a cost-effective solution without compromising on strength.

Applications of Fiberglass Reinforced Composite Materials

- Construction: Fiberglass composites are used in the construction industry for applications such as reinforcement of concrete structures, manufacturing of lightweight roofing panels, and fabrication of strong and durable profiles for windows and doors.

- Marine: Fiberglass reinforced composite materials are widely used in boat building and marine applications due to their resistance to corrosion and ability to withstand harsh environmental conditions. They are used in the construction of hulls, decks, and other structural components.

- Sports: Fiberglass composites find applications in sports equipment manufacturing, such as tennis rackets, hockey sticks, and surfboards. The high strength-to-weight ratio of fiberglass makes it an ideal choice for producing lightweight yet robust sporting goods.

“Fiberglass reinforced composites provide a cost-effective solution with impressive mechanical properties, making them versatile materials for a wide range of applications.”Ian Smith, Materials Engineer

Fiberglass reinforced composite materials offer a favorable combination of strength, cost-effectiveness, and versatility. Their applications range from construction to marine and sports industries, providing durable and lightweight solutions. As technology advances, the development of new resin systems and improved manufacturing processes will continue to enhance the mechanical properties of fiberglass composites, expanding their usage in various industries.

| Advantages | Disadvantages |

|---|---|

| – Excellent strength-to-weight ratio | – Less rigid compared to carbon fiber composites |

| – Corrosion-resistant | – Not as lightweight as carbon fiber composites |

| – Cost-effective | – Limited to specific applications due to lower stiffness |

| – Versatile in various industries |

Kevlar Reinforced Composite Materials

Kevlar is a formidable material that belongs to the category of aramid fibers. Known for its outstanding tensile strength and fatigue resistance, Kevlar surpasses steel in terms of strength-to-weight ratio. When combined with plastics, Kevlar fibers create composite materials that exhibit exceptional abrasion resistance and can withstand intense vibrations. This makes Kevlar composites highly sought after in industries such as automotive manufacturing, where components require both durability and resilience.

“The use of Kevlar composites in the automotive industry has revolutionized the production of various components.”

One remarkable application of Kevlar composites is in 3D printing, which allows for the creation of high-caliber and polished parts with excellent mechanical properties. The versatility of Kevlar composites makes them suitable for a wide range of industries and applications. From protective gear to aerospace components, Kevlar composites offer unparalleled strength and reliability.

Applications of Kevlar Composites:

- Automotive manufacturing: Kevlar composites are utilized in the production of various automotive components, including body panels, interior trims, and engine parts. These composites provide lightweight yet robust alternatives to traditional materials, contributing to fuel efficiency and enhanced performance.

- Sports equipment: Kevlar composites are commonly incorporated into sports equipment such as helmets, protective gear, and sporting goods. The exceptional strength and impact resistance of Kevlar composites make them an ideal choice for ensuring athlete safety.

- Marine industry: Kevlar composites find applications in the marine industry due to their excellent resistance to water, corrosion, and UV radiation. They are used in the construction of boat hulls, decks, and other structural components, providing strength and durability in challenging maritime environments.

| Industry | Application |

|---|---|

| Automotive | Body panels, interior trims, engine parts |

| Sports | Helmets, protective gear, sporting goods |

| Marine | Boat hulls, decks, structural components |

The unique properties of Kevlar composites, including their strength and resistance to various environmental factors, make them invaluable in numerous sectors. As technology advances, the applications of Kevlar composites are likely to expand even further, driving innovation and improving performance across industries.

Composite Materials in Nature

Composite materials are not a new invention but have been a part of nature for a long time. Many common structural materials in nature, such as wood, bamboo, and trees, are composites. Wood, for example, consists of fibers bound together, providing strength and stability. The use of composite materials in construction dates back to ancient times, with examples like adobe bricks mixed with dried grass or straw for added strength. Understanding the prevalence of composite materials in nature can provide insights into their versatility and durability in construction.

Bamboo is one natural composite that has been used for construction for hundreds of years. Since it’s composed of lignin and cellulose fibers, you can twist and fold it without worrying about it breaking. Since bamboo is both lightweight and strong, it is frequently used in building. Mother-of-pearl is a composite material created from oyster shells. It is also known as nacre. The protein matrix in nacre keeps the layers of calcium carbonate crystals together, making the material extremely durable. Because of the protection it provides, it is commonly used in mollusk shells. Many composite materials found in nature have been successfully used for building for many years.

Table: Examples of Natural Composites

| Natural Composite | Components | Properties | Applications |

|---|---|---|---|

| Wood | Cellulose fibers, lignin | Strength, stability | Construction, furniture |

| Bamboo | Cellulose fibers, lignin | Strength-to-weight ratio, flexibility | Construction, flooring |

| Nacre (mother-of-pearl) | Calcium carbonate crystals, protein matrix | Toughness, resilience | Jewelry, decorative items |

By harnessing the knowledge gained from nature, scientists and engineers continue to develop advanced composite building materials that offer even greater strength, durability, and sustainability. The use of composite materials in construction is not only revolutionizing the industry but also paving the way for more efficient and environmentally friendly building practices.

Origins of Composite Materials

Composite materials have a rich history that dates back thousands of years. Humans have long recognized the benefits of combining different materials to create stronger and more durable structures. One of the earliest examples of composite materials is the adobe brick, which combines mud or clay with dried grass or straw for added strength.

As civilizations advanced, so did the use of composite materials. Plywood, for example, emerged as a popular composite material, with layers of wood fibers aligned in different directions to provide optimal strength in all directions. This combination of materials creates a material that is highly resistant to compression and tension, making it ideal for building structures such as bridges and skyscrapers.

Over the years, composite materials have continued to evolve and find new applications in various industries. From aerospace to automotive to construction, composite materials have proven their worth in terms of strength, durability, and versatility. As technology advances, researchers are exploring innovative composite materials that offer enhanced properties and sustainability, paving the way for the future of construction.

Table: Examples of Composite Materials Throughout History

| Material | Origin | Application |

|---|---|---|

| Adobe Brick | Ancient civilizations | Construction |

| Plywood | Ancient Egypt | Construction, furniture |

| Reinforced Concrete | Ancient Romans | Construction |

| Composite Wooden Beams | Medieval Europe | Construction |

| Fiberglass | 20th century | Automotive, marine, aerospace |

Composite Building Materials in Modern Construction

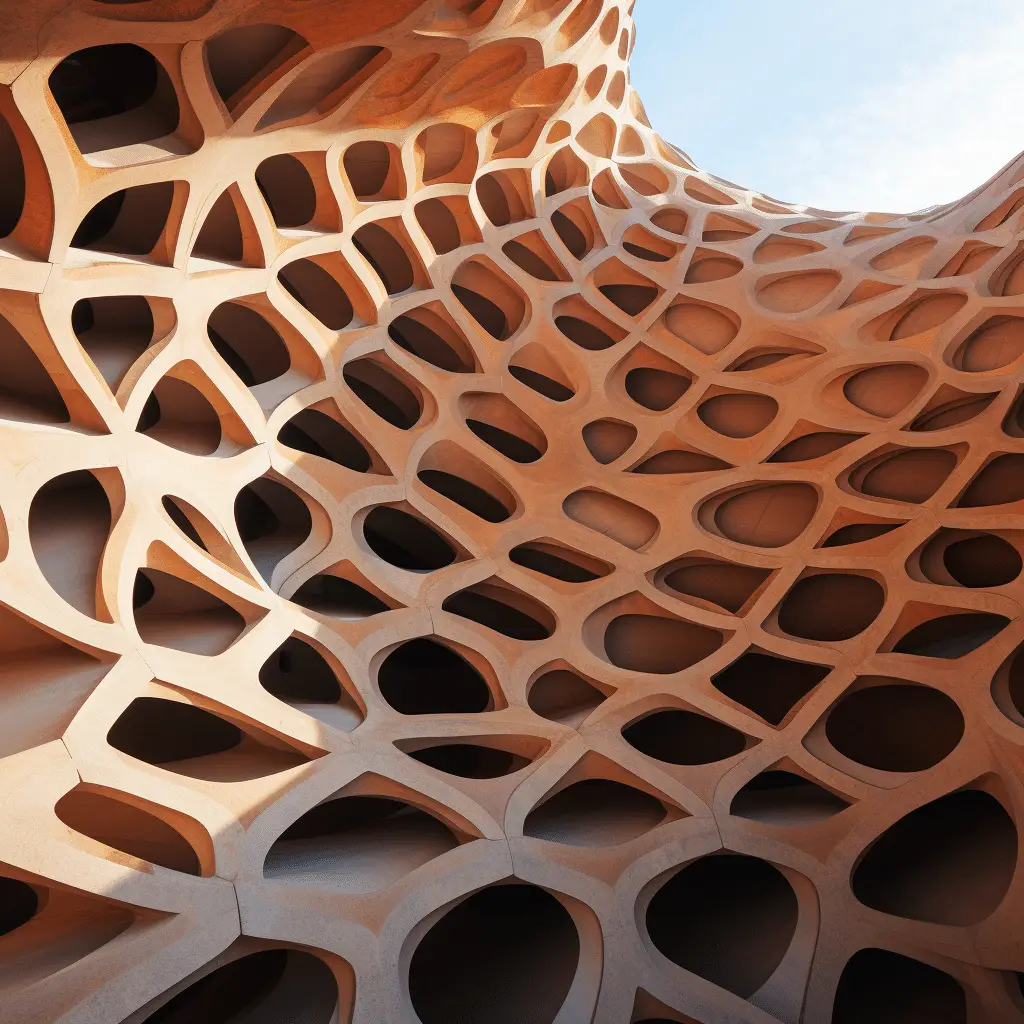

Composite building materials have become increasingly prevalent in modern construction projects due to their numerous advantages and versatility. These advanced materials offer a combination of durability, strength, and design flexibility that surpasses traditional materials like wood, concrete, and steel. More and more architects and builders are incorporating composite materials into their designs to achieve superior performance and meet the evolving demands of the construction industry.

Composites have many different uses in the building industry, ranging from residential and commercial structures to bridges and other infrastructure. Composites, also known as “modern building materials,” are materials that combine two or more different types of material. The resistance to corrosion and weathering that is inherent to reinforced plastics makes them ideal for use in exterior construction. In comparison to carbon fiber, fiberglass composites are much more affordable while still delivering excellent mechanical and thermal properties. Carbon fiber composites, on the other hand, excel in industries such as aerospace that place a premium on lightweight strength.

Composites have the advantage of being easily tailored and engineered to meet the specific requirements of any given construction project. Composites can be designed to mimic the appearance of wood or other organic materials while maintaining the durability and reliability of man-made materials. This paves the way for innovative, aesthetically pleasing, and essentially maintenance-free architecture. Composites are changing the construction industry by broadening the possibilities for architectural design and construction.

Advantages of Composite Building Materials in Modern Construction:

- Durability and resistance to corrosion, rot, and weathering.

- Superior strength-to-weight ratio, enabling lightweight and efficient designs.

- Flexibility in design, allowing for customized and innovative architectural solutions.

- Enhanced performance in specific applications, such as fire resistance or thermal insulation.

Table: Comparison of Composite Building Materials

| Material | Advantages | Applications |

|---|---|---|

| Reinforced Plastics | – Resistance to corrosion and weathering – Excellent strength-to-weight ratio | – Outdoor structures – Infrastructure components |

| Fiberglass Composites | – Cost-effective alternative to carbon fiber – Good mechanical and thermal properties | – Engineering prototypes – Marine applications |

| Carbon Fiber Composites | – Exceptional strength-to-weight ratio – High stiffness and tensile strength | – Aerospace components – Automotive parts |

As the field of materials science and manufacturing technology develops, it is anticipated that composites will become increasingly common in contemporary construction. Improvements in performance, sustainability, and cost-effectiveness are the primary goals of the ongoing research and development in the field of composites.

Advancements in Composite Building Materials

As technology continues to evolve, so do composite building materials. Researchers and engineers are constantly exploring innovative materials and manufacturing processes to improve the performance, durability, and sustainability of composites. The future of composite building materials holds great promise, with advancements that will revolutionize the construction industry.

Future Materials: Bio-based Composites

One exciting area of development is bio-based composites. These composites are made from renewable resources such as plant fibers, natural resins, and biodegradable polymers. Bio-based composites offer several advantages, such as reduced environmental impact, lower carbon footprint, and improved resource efficiency.

The Role of Nanocomposites

Nanocomposites are another area of advancement in the composite building material industry. These composites utilize nanotechnology to enhance the properties of traditional composites. By incorporating nanoparticles into the composite matrix, materials can exhibit improved mechanical strength, thermal stability, and electrical conductivity. Nanocomposites have the potential to revolutionize several sectors, including aerospace, automotive, and infrastructure.

The use of nanocomposites in construction can lead to lighter and stronger structures, reducing material consumption and construction costs. These materials can also offer better insulation properties, resulting in improved energy efficiency in buildings. With ongoing research and development, the future of nanocomposites in construction looks promising.

| Advancements in Composite Building Materials | Key Features |

|---|---|

| Bio-based Composites | Renewable resources, reduced environmental impact, improved mechanical properties |

| Nanocomposites | Nanotechnology, enhanced mechanical strength, thermal stability, and electrical conductivity |

In conclusion, advancements in composite building materials are driving the future of construction. With the development of bio-based composites and nanocomposites, the industry is moving towards sustainable and high-performing materials. These advancements will not only benefit the construction sector but also contribute to a greener and more efficient built environment. As technology continues to progress, we can expect even more exciting breakthroughs in composite building materials.

Conclusion

Composites are changing the face of the construction industry and the way buildings are constructed in the future. Reinforced polymers, fiberglass, and carbon fiber composites are examples of these adaptable and long-lasting materials, which have many uses in the building industry.

Composites have the advantages of being resistant to the elements, lightweight, and strong. They provide more leeway in terms of layout, which opens the door to creative new building approaches. Composites and nanocomposites made from renewable resources are of interest to scientists because of their superior qualities and long-term viability. Construction techniques, energy efficiency, and environmental effect may all benefit from the use of these materials. Composite construction materials will be essential in altering the way we build as the industry moves toward a more sustainable and innovative future.

In conclusion, composites are changing the face of the construction business and ushering in a new era of cutting-edge construction practices. With their unique features and continual improvements, composite materials are primed to drive innovation, sustainability, and efficiency in construction operations.

FAQ

What are composite building materials?

Composite building materials are engineered from two or more materials with different properties, resulting in high-performing building materials.

What are some examples of composite building materials?

Examples of composite building materials include concrete, reinforced plastics, cement, steel-reinforced concrete, and composite wooden beams.

What types of composite materials are there?

There are different types of composite materials, such as reinforced plastics, thermoset plastics, and thermoplastics.

What are the advantages of composite building materials?

Composite building materials offer advantages such as durability, strength, resistance to rot, insects, and moisture, and the ability to resemble real wood.

Are there any disadvantages to using composite building materials?

Some disadvantages of composite building materials include potential fading when exposed to UV light, and possible breakdown or deterioration over time due to moisture and UV light exposure.

What is composite 3D printing?

Composite 3D printing is a technology that combines composite materials, such as carbon fiber, fiberglass, or Kevlar, with a plastic matrix to create strong and lightweight parts.

What are some applications of carbon fiber reinforced composite materials?

Carbon fiber reinforced composites are commonly used in industries such as aerospace, automotive, and construction for their exceptional strength-to-weight ratio.

What are some applications of fiberglass reinforced composite materials?

Fiberglass reinforced composites find applications in engineering prototypes and end-use parts that require robust mechanical and thermal resilience, in industries such as construction, marine, and sports.

What are some applications of Kevlar reinforced composite materials?

Kevlar reinforced composites are utilized in the automotive industry and other industries to manufacture components that require exceptional tensile strength, fatigue resistance, and vibration resistance.

Have composite materials been used throughout history?

Yes, composite materials have been used for thousands of years, with examples like adobe bricks mixed with dried grass or straw for added strength.

How have composite materials influenced modern construction?

Composite building materials have revolutionized modern construction by offering durability, strength, versatility, and improved design flexibility.

What does the future hold for composite building materials?

The future of composite building materials includes advancements in construction methods, energy efficiency, and environmental impact, as new technologies and materials are developed.