How To Make Shelves For Storage

Introduction

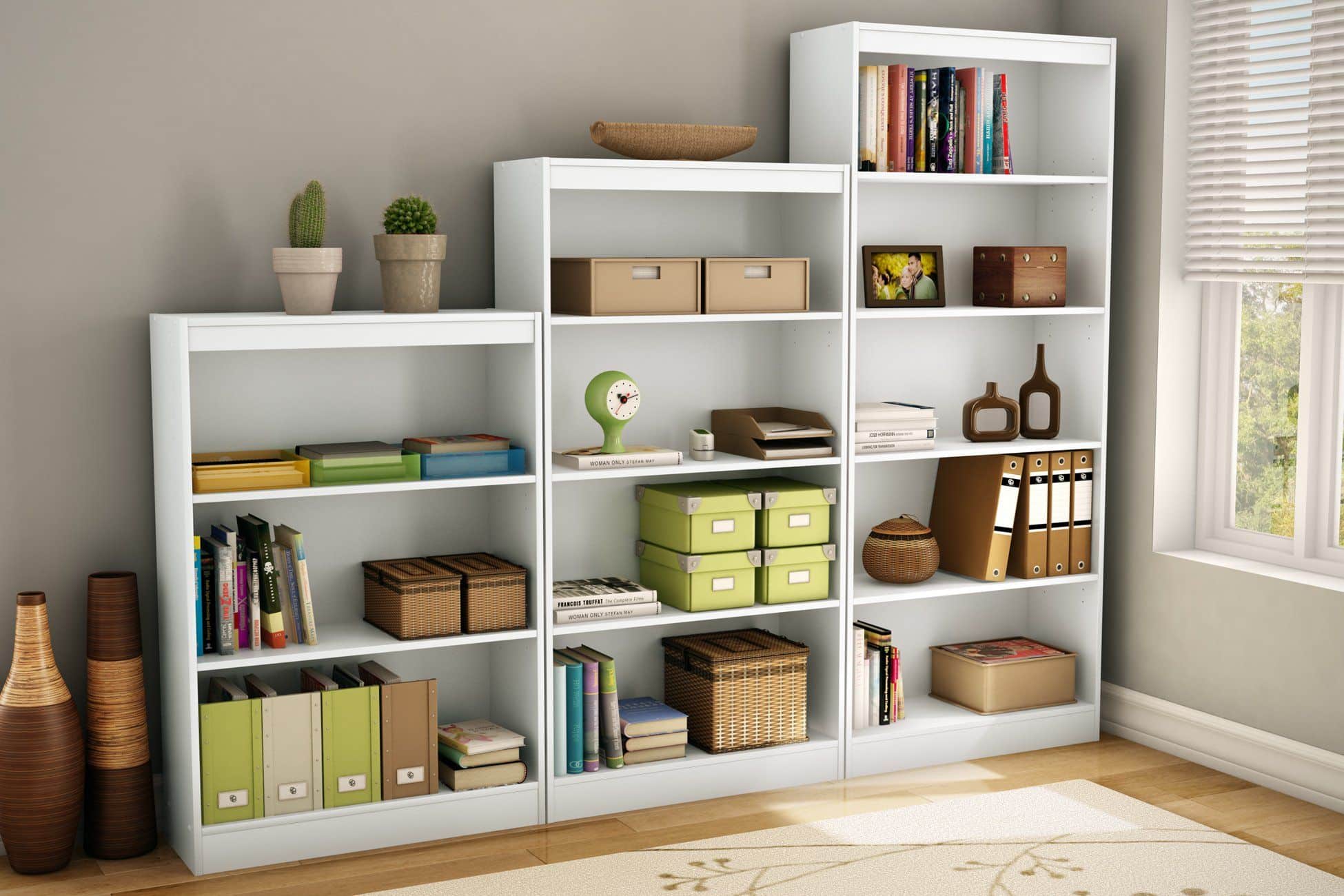

How To Make Shelves For Storage: First and foremost, take measurements of the area where you plan to install the shelves. Consider the height, width, and depth you’ll need to accommodate your items. This crucial step will help you determine the amount of materials required and guide you in designing shelves that perfectly fit your space. Whichever option you choose, we’ll guide you step-by-step, from preparing the materials to assembling the final product.

Next, let’s talk about materials. Depending on your preference and budget, you can choose from a range of kitchen cabinets materials such as wood, plywood, MDF (Medium-Density Fiberboard), or metal. Each material has its strengths and characteristics, so select the one that best suits your storage needs and complements your decor. Finally, don’t hesitate to get creative with the finishing touches of your shelves. You can choose to paint, stain, or varnish the wood to match your decor, or leave them natural for a rustic charm. The possibilities are endless, and the sense of accomplishment you’ll feel once you’ve completed your custom-made storage shelves will be truly gratifying.

Furthermore, investing in the right tools is essential for a successful shelf-building project. Basic tools like a measuring tape, level, hammer, screwdriver, and power drill will be invaluable throughout the process. Don’t forget to prioritize safety by wearing appropriate protective gear, including safety goggles and gloves. Freestanding shelves are versatile and easy to move around, while wall-mounted shelves save floor space and provide a clean, modern look.

What material do you use for shelves?

Plywood

First and foremost, the wood you use for making bookshelves will impact the design as well as the cost of your project. ¾-inch plywood is considered the industry standard, thanks to it being strong yet inexpensive—especially when compared with some solid woods.

Acrylic or Lucite

Solid wood is a timeless and popular choice for shelves due to its natural beauty and strength. Oak, pine, maple, and walnut are commonly used hardwoods, each offering unique grain patterns and colors. Solid wood shelves can hold a substantial amount of weight and are ideal for displaying books, decor, and heavier items.

They also lend warmth and elegance to any space, making them a versatile option for both traditional and contemporary settings. However, solid wood shelves can be more expensive than other materials, and they may require regular maintenance to prevent warping or splitting.

Plywood

Plywood is an affordable and versatile option for building shelves. It consists of several layers of thin wood veneers glued together, making it durable and resistant to warping. Plywood shelves are lighter than solid wood, making them easier to install and move around.

They come in various grades, with higher grades offering smoother surfaces for a more polished look. While plywood can be painted or stained, its edges may require veneer or edge banding for a finished appearance.

MDF (Medium-Density Fiberboard)

MDF is a type of wood that is made by pressing wood fibers, glue, and wax together. It is a cheap option for shelves, and the smooth, even surface is great for painting. MDF shelves don’t expand and shrink as much when the temperature or humidity changes, so they can be used in places with different conditions. MDF, on the other hand, is not as strong as solid wood or plywood, and it can sag under heavy loads if it is not properly supported.

Particleboard, which is made of wood chips, shavings, and resin pressed together, is another cheap choice for shelves. Even though it isn’t as strong as board or solid wood, it can still be used to store light things. Since moisture can damage the raw sides of particleboard, it is best to use it for shelves with a veneer or laminate finish.

What can I use instead of shelves?

5 alternative shelving solutions

- 1 Steel Shelving Mezzanines. These are self-supporting types of industrial shelving.

- 2 Floating Shelves. As the name suggests, these shelves look as if they’re floating.

- 3 Shelves Held Up By Chains.

- 4 Slanted Wire Shelving With Bins.

- 5 Wire Shelving.

Floating wall cubes are a great way to replace regular shelves. These structures that look like boxes can be placed on the wall for a modern and simple look. They come in different sizes and shapes, which lets you make patterns that look good. Floating cubes are great for showing off small pieces of decor, books, and collectibles. They work especially well in small areas or as an alternative to a traditional bookshelf.

Pegboards are useful and flexible ways to store things. A pegboard is a flexible way to store tools, craft items, kitchen tools, and more. It’s easy to add hooks, baskets, and shelves. Pegboards are a great way to organize and show off things you use often and want to keep close by. They are also a great thing to have in garages, workshops, and hobby rooms.

Sizes and shapes

By turning an old ladder into shelves, you can turn it into an eye-catching way to store things. Just lean the ladder against the wall and use the rungs as homemade shelves. This charming and rustic display is a great way to show off plants, photo frames, and other decorating items. You can paint the ladder to match your style, or you can leave it as is for a more natural look.

With a little imagination, wooden crates can be turned into rustic wall shelves. You can stain or paint the crates any color you want and then hang them on the wall in different ways. These crates are great for keeping books, magazines, and other things. Because they are open, you can show off their contents in a way that is neat and looks good.

How thick should plywood be for shelves?

3/4 inch

For shelves, the plywood should be at least 3/4 inch thick. Plywood pieces come in thicknesses of 1/4 inch, 3/8 inch, 1/2 inch, 5/8 inch, and 3/4 inch. Usually, you have to place a special order for plywood pieces that are thicker than 3/4 inches.

The weight potential of your shelves is the first thing to think about when choosing the thickness of your plywood. Think about what you want to store, how much it will all weigh, and how evenly it will be spread across the shelves.

For lighter things like books, small home art, and clothing, 1/2-inch (12mm) plywood may be enough. But for heavier things like tools, electronics, or food appliances, it’s best to choose thicker plywood, like 3/4-inch (18mm) or even 1-inch (25mm), to make sure there’s enough support.

Plywood Shelves

The space between the supports or brackets that hold the shelves up is called the span. The wider the span, the more likely it is that big loads will cause the plywood to bend and sag. For longer spans, you need thicker boards to keep the structure strong. If you can’t add more supports or brackets, you might want to use stronger plywood to make up for the longer span.

Different kinds of plywood have different strengths and ways of holding things together. For example, Baltic birch plywood is known for being strong and stable, which makes it good for shelves that are smaller but can hold more weight. On the other hand, a standard construction-grade plywood panel may need to be thicker to be as strong.

When picking the thickness of plywood for shelves, it is also important to think about how the shelves will look. Thicker plywood can look stronger and more solid, which may be better for some kinds of design. On the other hand, thinner plywood can be used to make shelves that look sleek and simple, especially when they are floating or fixed on the wall.

Can you use plywood for shelves?

Plywood is ideal for pantry shelves because its edges can be finished with wood trim or iron-on veneer banding. Because plywood is strong (yet inexpensive compared to other solid woods), ¾-inch is usually considered the industry standard.

One of the primary reasons to use plywood for shelves is its exceptional strength and durability. Plywood is made by gluing together multiple layers of thin wood veneers, called plies or lamina, with each layer’s grain direction alternating at right angles.

This cross-grain construction gives plywood excellent dimensional stability, reducing the likelihood of warping or twisting over time. The layers also provide strength, making plywood shelves capable of supporting heavy loads without sagging or bowing.

Compared to solid wood or other engineered materials, plywood is a cost-effective option for shelving projects. It is more affordable than solid wood while still offering similar strength and stability. This cost-effectiveness allows you to build sturdy and reliable shelves without breaking the bank, making plywood a practical choice for those on a budget.

Plywood’s versatility allows it to be used for various shelving applications. Whether you need freestanding bookshelves, wall-mounted display shelves, or functional storage units, plywood can be easily cut and shaped to meet your specific needs. Additionally, plywood can be painted, stained, or finished to match any decor style, giving you the freedom to customize your shelves to suit your space.

Plywood is relatively easy to work with, even for those with minimal carpentry experience. It cuts cleanly with basic woodworking tools, and its uniform surface ensures a smooth finish. If you plan to undertake a DIY shelf-building project, plywood is a beginner-friendly material that allows you to achieve professional-looking results with some basic skills and tools.

What size should shelves be?

The shelves shouldn’t be too deep.

The standard depth of most shelves is 16 to 20 inches deep. The highest shelf should be shallower, like 12 inches deep, to make those items easier to access. If you find that stuff seems to get pushed to the back and forgotten about, you should consider even shallower shelves.

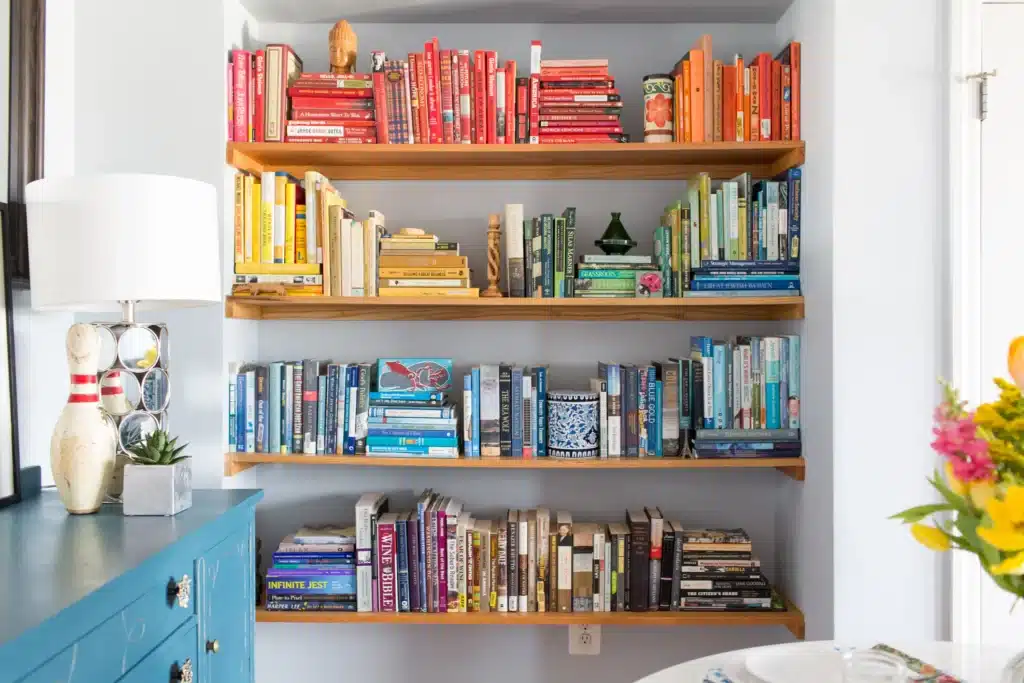

The first step in determining shelf size is understanding the purpose and function they will serve. Are the shelves intended for displaying decorative items, storing books, organizing kitchen supplies, or holding heavy equipment in a garage? Different items have different space requirements, so considering the intended use of the shelves is crucial in determining their size.

The dimensions of the space where the shelves will be installed play a significant role in determining their size. Measure the height, width, and depth of the area where you plan to place the shelves. Ensure that the shelves fit comfortably within the space without overwhelming or obstructing the surrounding furniture or traffic flow.

Consider the size and quantity of items you wish to store on the shelves. For example, if you plan to display large decorative items or store oversized kitchen appliances, you’ll need larger and sturdier shelves. On the other hand, smaller shelves are suitable for organizing books, decor pieces, or smaller items like spices or toiletries.

The thickness and quality of the shelf material, such as plywood or solid wood, affect the weight capacity of the shelves. Thicker and stronger materials can support heavier loads. Be sure to choose shelf dimensions that can safely accommodate the weight of the items you intend to store without causing sagging or instability.

What can I use instead of wood for shelves?

7 Smart Alternatives to Wood

- 1- Melamine. At Diplomat Closet Design, melamine is our #1 choice as a wood alternative.

- 2- Engineered Wood.

- 3- Modern Plywood, OSB, and MDF.

- 4- Bamboo.

- 5- Cork.

- 6- Textured/Colored Concrete.

- 7- Wood-Effect Tiles.

- Fast Lead Times and Lower Prices.

Glass shelves provide a sleek and modern look that can enhance the visual appeal of any space. They are perfect for displaying decor items, collectibles, or even creating a minimalist storage solution. Glass shelves are easy to clean, don’t warp, and allow light to pass through, adding a sense of openness to a room. They are ideal for areas where you want to create an airy and uncluttered atmosphere.

Metal shelves are durable, sturdy, and can withstand heavy loads, making them a practical alternative to wood for storage solutions. Steel, aluminum, and wrought iron are common materials used for metal shelves. They are often used in garages, workshops, and industrial-style spaces due to their industrial look and high weight capacity. Metal shelves are resistant to moisture and pests, making them suitable for outdoor or damp environments.

Plastic or acrylic shelves are lightweight, affordable, and resistant to water, making them suitable for bathrooms, kitchens, and outdoor spaces. They are available in various colors and styles, allowing you to find options that match your decor. Plastic shelves are easy to clean and low-maintenance, making them an excellent choice for busy households.

Wire shelves are versatile and practical alternatives to wood. They are lightweight, allowing for easy installation and flexibility in shelving configurations. Wire shelves are commonly used in closets, pantries, and storage rooms. The open design allows for proper ventilation and prevents dust accumulation. Additionally, wire shelves are an excellent solution for organizing clothing, kitchen supplies, and other items with different shapes and sizes.

What material are lightweight shelves?

The aluminum gives light shelves their conductive and lightweight properties. Additionally, aluminum and ACM provide a metallic surface that is easy to paint or coat with protective finishes. Frosted glass has also been used for light shelf materials.

Particleboard is a cost-effective and lightweight option for shelves. It is made from compressed wood particles and adhesive, resulting in a relatively lightweight yet sturdy material. Particleboard is easy to cut and shape, making it ideal for DIY projects or quick shelving solutions. However, it is essential to consider the weight capacity, as particleboard may not be suitable for heavy loads or long spans without proper support.

MDF is similar to particleboard but made from finer wood fibers, resulting in a smoother and denser surface. MDF is lightweight, easy to work with, and offers a more refined look compared to particleboard. It is commonly used for shelving in areas where appearance matters, such as living rooms, bedrooms, or home offices. Like particleboard, MDF has limitations on weight capacity and may require additional supports for heavy items.

Honeycomb core shelves consist of a cardboard or paper honeycomb structure sandwiched between two outer panels, often made of wood or laminate. This construction provides exceptional strength and stability while keeping the overall weight of the shelves low. Honeycomb core shelves are a popular choice for portable or modular shelving systems due to their lightweight and easy assembly.

Plastic and acrylic shelves are among the lightest options available for shelving. These materials are perfect for situations where water resistance and easy maintenance are important factors. Plastic and acrylic shelves are commonly used in bathrooms, kitchens, and outdoor spaces, as they are not susceptible to moisture damage and are effortless to clean.

What is the strongest type of plywood?

Marine plywood

What Is the Strong Plywood Type? The strongest plywood is marine plywood, of which the layers are glued together with excellent quality adhesives.

Marine plywood is made from high-quality wood veneers, usually from tropical hardwoods such as Okoume, Meranti, or Sapele. These hardwoods possess superior strength and resistance to decay and are well-suited for marine-grade applications. The veneers are bonded together with waterproof glue using a specialized manufacturing process, resulting in a plywood panel that is highly resistant to delamination, warping, and splitting.

One of the most significant advantages of marine plywood is its excellent waterproof and moisture-resistant properties. The special adhesive used in its construction provides exceptional resistance to water, making it ideal for use in marine environments, outdoor furniture, and areas prone to high humidity or wet conditions.

Marine plywood is often subjected to a boiling water test, which further demonstrates its strength and resistance to moisture. This test involves boiling the plywood panel for several hours and assessing its structural integrity afterward. Marine plywood passes this test with flying colors, confirming its ability to withstand water exposure without compromising its strength.

Due to its construction and high-quality materials, marine plywood is incredibly durable and long-lasting. It is resistant to rot, insects, and fungal attacks, making it a top choice for applications where wood is continuously exposed to the elements or moisture.

Conclusion

Remember, the key to a successful shelf-building project lies in accurate measurements, using appropriate tools and materials, and prioritizing safety at all times. Whether you opted for freestanding shelves for versatility or wall-mounted shelves to maximize space, your dedication and attention to detail will shine through in the final product. Remember, the beauty of DIY projects is not only in the final product but also in the journey itself.

Now that you’ve mastered the art of making shelves, the possibilities are endless. You can apply these newfound skills to tackle other DIY projects, customize furniture, or even create more complex storage solutions. The DIY world is your oyster, and there’s no limit to what you can achieve with your newfound knowledge. Embrace any challenges you encountered along the way as valuable learning experiences, and celebrate your ability to overcome them. Each step you took, from planning and measuring to cutting and assembling, has contributed to your growth as a DIY enthusiast.

As you continue on your DIY journey, don’t be afraid to experiment, explore new designs, and seek storage rack inspiration from other crafters and creators. Embrace the joy of building and crafting with your own hands, and remember that every project is an opportunity to learn and grow. Now that you have the skills and confidence to build shelves for storage, consider sharing your knowledge with friends, family, or fellow DIY enthusiasts. Inspire others to embark on their own crafting adventures, and support one another in this exciting world of hands-on creativity.