How Dangerous Is Lead Solder In Plumbing

Introduction

How Dangerous Is Lead Solder In Plumbing: Lead solder has been widely used in plumbing for many years due to its favorable properties, such as low melting point, malleability, and durability. However, its use has raised concerns regarding public health and safety. Lead is a highly toxic metal that can cause severe health issues, particularly when it enters the human body through drinking water contaminated by lead solder.

Lead solder used in plumbing pipes can gradually leach into the water supply, especially in older homes where lead-based materials were commonly used. When consumed over extended periods, even low levels of lead exposure can lead to serious health problems, particularly among infants, young children, and pregnant women. The effects of lead poisoning include developmental delays, impaired cognition, kidney damage, and an increased risk of cardiovascular diseases.

Recognizing the hazards associated with lead solder, regulatory bodies and governments have implemented measures to reduce lead exposure in plumbing systems. Many countries have banned or restricted the use of lead solder in new construction and plumbing fixtures, promoting alternative materials that are considered safer.

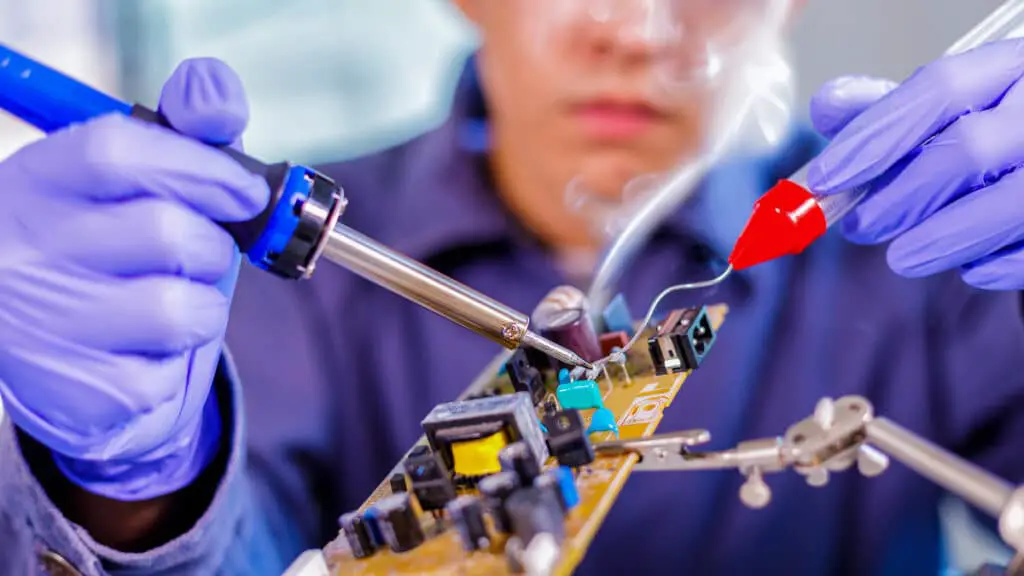

Is It Dangerous To Work With Lead Solder?

When people solder, they can be introduced to lead. If lead is handled poorly, it can cause long-term health problems like reproductive issues, digestive issues, memory and focus issues, and pain in the muscles and joints.

Lead solder can be very dangerous to work with if the right safety measures are not taken. Lead is a dangerous metal that can hurt people’s health very badly. Especially if they breathe it in or eat it. Poisoning with lead can hurt many parts of your body, like your nervous system, kidneys, and reproductive system. It can also hurt kids’ growth and make it hard for them to learn.

The breathing in of lead fumes is one of the main risks of using lead solder. Lead solder gives off poisonous fumes when heated, which are easy for people working with it to breathe in. Lead poisoning can happen if you are exposed to these fumes for a long time. To keep from breathing in too many lead fumes, it is important to work in a well-ventilated area or with a local air ventilation system.

There is also the risk of coming into close contact with lead solder. It is possible for lead to get into your bloodstream through your skin if you work with lead solder without keeping yourself safe by wearing gloves. If you have cuts or scrapes on your hands, this could be very dangerous.

Is Lead Solder Safe For Plumbing?

But until 1986, copper lines were often joined together with solder that was made of lead. New plumbing in homes and plumbing repairs must now use lead-free solder and materials. This is the law at the government level. Scratching the pipe with a key or knife is one way to find out if the plumbing in a house has lead in it.

People don’t think lead solder is safe for use in pipes, especially in systems that handle drinking water. Lead solder has been used in pipes for a long time, but its use has gone down a lot since people learned how dangerous it is to your health. Lead is a dangerous metal that can get into the water system . And is very bad for your health if you drink or eat it.

When pipe joints are sealed with lead solder, the lead could dissolve and get into the water that is flowing through the system. This is especially scary for drinking water, because lead poisoning has been linked to kids being less developed. Having higher blood pressure, kidney damage, and other health problems.

Several rules and laws have been put in place to limit or ban the use of lead solder in plumbing systems in response to these worries. Lead solder is either tightly regulated or not allowed at all in many places where potable water is used. People are now more interested in lead-free solder options, like tin-antimony, tin-copper, or silver-based solders, which are safe for plumbing uses.

Is Lead Solder On Copper Pipes Dangerous?

Plumbing installed before 1930 is most likely to contain lead. Copper pipes have replaced lead pipes in most residential plumbing. However, the use of lead solder with copper pipes is widespread. Experts regard this lead solder as the major cause of lead contamination of household water in U. S. homes today.

Lead solder on copper pipes can potentially be dangerous, particularly if the pipes are used for carrying potable water. Lead is a toxic metal that can leach into the water, leading to health risks when ingested. Therefore, it is important to understand the potential dangers and take appropriate measures to mitigate them.

When lead solder is used on copper pipes, there is a risk of lead leaching into the water over time. This is especially true for older plumbing systems that may have used lead solder in the past. As water flows through the pipes, it can come into contact with the solder. Causing the lead to dissolve and contaminate the water supply. Prolonged exposure to lead-contaminated water can result in lead poisoning. Which can have detrimental effects on human health, particularly in children.

To address this concern, regulations and standards have been established in many jurisdictions to limit or prohibit the use of lead solder in plumbing systems, especially those carrying potable water. The focus has shifted towards lead-free solder alternatives, which are considered safer for plumbing applications.

How Do You Identify Lead Solder?

Rub the test area with an activated LeadCheck® Swab. If the tip of the LeadCheck® Swab is pink or red, there is lead. Swab tips exposed to leaded solder will turn pink or red instantly. Any remaining dye, if negative, will become pale yellow to colorless.

Identifying lead solder can be done through visual inspection and by examining the markings on the solder or its packaging. Here are some ways to identify lead solder:

Visual Inspection: Lead solder typically has a dull, silver-gray color. It may appear slightly darker than other types of solder. However, visual inspection alone may not be sufficient to determine if the solder contains lead, as lead-free solders can also have a similar appearance.

Markings on the Solder: Manufacturers often label their solder with specific markings or codes that indicate its composition. Look for markings such as “Pb-Sn” or “60/40,” which signify the presence of lead. These markings indicate that the solder contains lead (Pb) and tin (Sn) in a 60/40 ratio. Which is a common composition for lead solder. However, it’s important to note that not all lead solders may have explicit markings indicating their composition.

Packaging Information: The packaging of the solder may provide information about its composition. Check for labels or descriptions that mention the presence of lead. It is worth noting that lead-free solders are often clearly labeled as such, indicating that they are free from lead or contain minimal lead content.

Testing: If you want to be absolutely sure about the presence of lead in the solder, you can use lead testing kits or consult professional testing services. These tests involve collecting a small sample of the solder. And using specialized tools or chemicals to determine its lead content accurately.

Is Lead Solder Legal?

Section 1417(a)(3) of the Safe Drinking Water Act (SDWA) prohibits the sale of solder and flux that is not lead-free unless the solder or flux bears a prominent label stating that it is illegal to use the solder or flux in the installation or repair of any plumbing providing water for human consumption.

The legality of lead solder varies depending on the jurisdiction and its specific regulations. In many countries, the use of lead solder in certain applications, particularly those involving potable water systems, has been heavily restricted or outright banned. This is due to the recognized health hazards associated with lead exposure.

Regulations regarding lead solder often aim to protect public health and the environment. These regulations may set maximum allowable limits for lead content in solder or outright prohibit its use in specific applications. The restrictions typically focus on areas where lead can leach into drinking water. Such as plumbing systems or products that come into contact with food or beverages.

In the United States, for example, the Safe Drinking Water Act (SDWA) establishes limits on lead content in plumbing materials, including solder. The Environmental Protection Agency (EPA) has set a limit of 0.2% lead for solder and flux used in plumbing systems.

Similarly, the European Union has implemented the Restriction of Hazardous Substances (RoHS) directive. Which restricts the use of certain hazardous substances, including lead, in electrical and electronic equipment. Lead solder is specifically addressed in this directive, and its use is restricted for most electronic applications.

How Strong Is Lead Solder?

as a function of processing temperature and time. The pull strengths are in the range of 70 MPa (10.2 ksi) to 140 MPa (20.4 ksi), which are considerably higher than the bulk tensile strength of Sn-Pb solder, which is 30 MPa (4.4 ksi) [11].

Lead solder is not particularly strong compared to other solder alloys. Its primary purpose is to provide a low melting point and facilitate the joining of metals through a process called soldering. The strength of lead solder primarily depends on the specific composition and the intended application.

Lead solder typically consists of a combination of lead and tin. With a common composition being 60% tin and 40% lead (60/40 solder). The addition of lead to the alloy lowers the melting point, making it easier to work with. However, lead solder is relatively soft and has a lower tensile strength compared to other solder alloys.

The strength of lead solder can be sufficient for many electronic and electrical applications where mechanical stress or load-bearing requirements are not significant. It is commonly used in circuit board assembly, electrical connections, and various other low-stress applications.

How Does Lead Solder Contaminate Water?

Lead solder can contaminate water when it corrodes or leaches into the plumbing system. Over time, acidic or alkaline water, as well as water with high chlorine levels, can cause the solder joints to deteriorate. Leading to the release of lead particles into the water supply.

Lead solder can contaminate water through a process called leaching. Leaching occurs when water comes into contact with lead-soldered joints or surfaces, causing the lead to dissolve and mix with the water supply. This contamination can pose serious health risks when the water is consumed or used for cooking, as lead is a toxic metal.

There are a few key factors that contribute to lead solder leaching:

Corrosion: Over time, the water flowing through plumbing systems can corrode the soldered joints. Causing the protective layer on the solder to deteriorate. This corrosion allows water to directly contact the lead solder, increasing the potential for lead to dissolve into the water.

Low pH and high acidity: Water with low pH or high acidity is more likely to cause lead solder to leach. Acidic water can corrode the protective layer on the solder, facilitating the release of lead into the water.

Extended contact time: The longer the water remains in contact with the lead solder, the higher the likelihood of lead leaching. Stagnant water or water that sits in the plumbing system for extended periods can increase the risk of contamination.

How Can I Determine If My Plumbing System Contains Lead Solder?

If your plumbing system was installed before the 1980s, there is a higher likelihood that lead solder was used. You can have your water tested for lead by contacting a certified laboratory or a local health department. Additionally, a professional plumber or home inspector can help identify the presence of lead solder in your plumbing system.

Determining if your plumbing system contains lead solder can be done through a few methods:

Visual Inspection: Examine visible soldered joints in your plumbing system. Lead solder typically has a dull, silver-gray color and may appear slightly darker than other types of solder. However, visual inspection alone may not be conclusive, as lead-free solders can also have a similar appearance.

Age of the Plumbing System: If your plumbing system was installed before the late 1980s or early 1990s, there is a higher likelihood that it contains lead solder. During that period, the use of lead solder in plumbing systems became less common due to growing awareness of its health hazards.

Water Testing: Conduct water testing to determine the lead levels in your water supply. This can be done through a professional testing service or by using a lead testing kit. Testing water samples from various faucets in your home can help identify if lead is present and whether it is originating from the plumbing system.

Consultation with a Professional: Seek advice from a professional plumber or a qualified inspector. They can examine your plumbing system, assess the solder used, and provide insights on the presence of lead solder.

Conclusion

Lead solder used in plumbing systems poses a significant danger to human health due to its ability to contaminate drinking water with toxic lead particles. The ingestion of lead-contaminated water can result in severe health issues. Particularly among vulnerable populations such as infants, young children, and pregnant women. The long-term effects of lead poisoning include developmental delays, impaired cognition, kidney damage, and an increased risk of cardiovascular diseases.

Many countries have implemented bans or restrictions on the use of lead solder in new construction and plumbing fixtures. These measures promote the adoption of safer alternative materials, ensuring the provision of clean and uncontaminated drinking water.

However, it is essential to recognize that the dangers of lead solder in plumbing leads persist in older buildings where lead-based materials were commonly used. In such cases, homeowners should consider testing their water for lead contamination and take appropriate measures to mitigate the risk, such as installing water filters or replacing plumbing components containing lead solder.